Constant-temperature pot

A constant temperature, outer pot technology, applied in the field of kitchen utensils, can solve the problems of chocolate burning sticking to the pot, difficult temperature control, inability to keep warm, etc., and achieve the effects of long heat preservation time, constant temperature, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

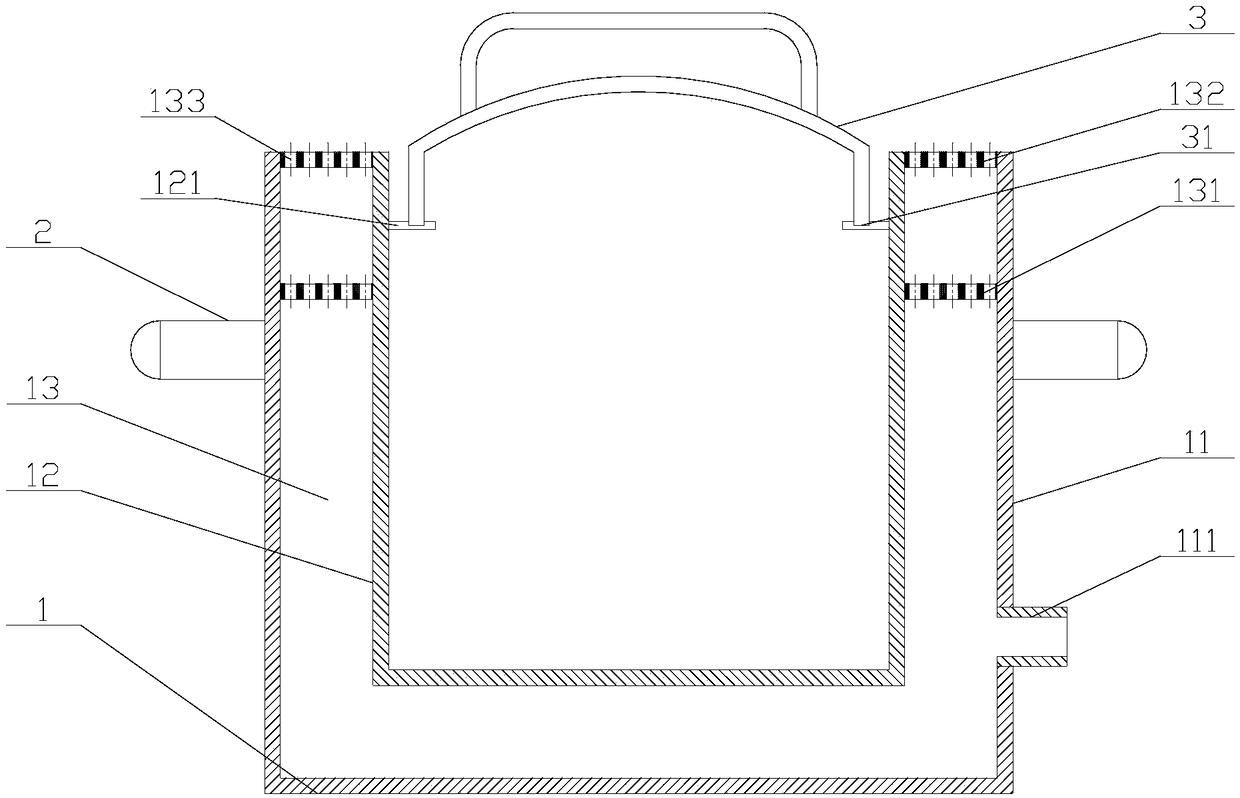

[0012] The present invention as figure 1 As shown, a constant temperature pot includes a pot body 1 with an upper opening and a handle 2 arranged on the outer wall of the pot body 1, the top of the pot body 1 is covered with a pot cover 3, and the pot body includes an outer pot 11 and an inner pot 12, the inner pot 12 is located inside the outer pot 11, a cavity 13 is provided between the outer pot 11 and the inner pot 12; the cavity 13 is filled with liquid, such as water, When in use, heat the outer pot to make the water in the cavity boil, and use boiling water as the heat source to heat the inner pot so that the inner pot is always kept at the boiling point of the water. When using melted chocolate, it can achieve a constant temperature, and the melting effect is good without sticking pot. And when not heating, due to the residual temperature of the water, the food placed in the inner pot is kept warm, and the heat preservation time is long and the effect is good.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com