High-precision process of high-speed transmission shaft

A high-speed transmission, high-precision technology, applied in the field of high-precision technology, can solve the problems of inability to guarantee the precise size and low efficiency, and achieve the effect of improving the dimensional accuracy of the workpiece, improving the overheating structure, and improving the internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

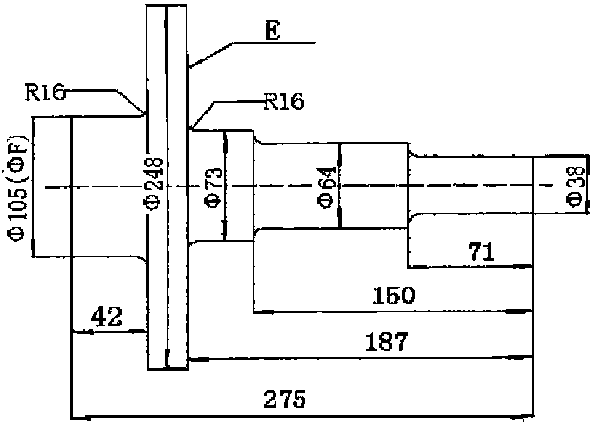

[0042] A high-precision process for a high-speed transmission shaft, comprising the following steps:

[0043] 1) Material preparation: forgings;

[0044] 2) Rough turning: processing according to the process sketch;

[0045] 3) heat treatment;

[0046] 4) Finishing: clamp the φ50 outer circle at the right end, and align the outer circle at the left end and the F surface;

[0047] ①Grind 0.3~0.4 and surface A of the outer circle φG of the car to ensure that there is a margin in the total length, and the grate teeth will not be processed temporarily;

[0048] ②For the φF and F surfaces of the outer circle of the car, ensure that there is a margin on the E surface, and the grinding amount of the two outer circles is 0. 3 to 0. 4, and the 13. 5° inclined plane and the tooth are not processed temporarily;

[0049] ③ Drill M24 × 1. 5 bottom hole, φ 22. 5 deep 185 , inner hole φD grinding amount 0. 2 ~ 0. 3. φE will not be processed temporarily, φD hole finish chamfering 2 × 60°; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com