High-accuracy universal adjustable V-shaped positioning tool

A positioning tooling, high-precision technology, applied in the field of machining, can solve the problems of difficult to align the horizontal center of the V-shaped block, unable to meet the positioning requirements, and large adjustment torque, so as to reduce the input cost and process preparation period, and ensure the product Stable and reliable effect of processing quality and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, technical solution of the present invention will be further described:

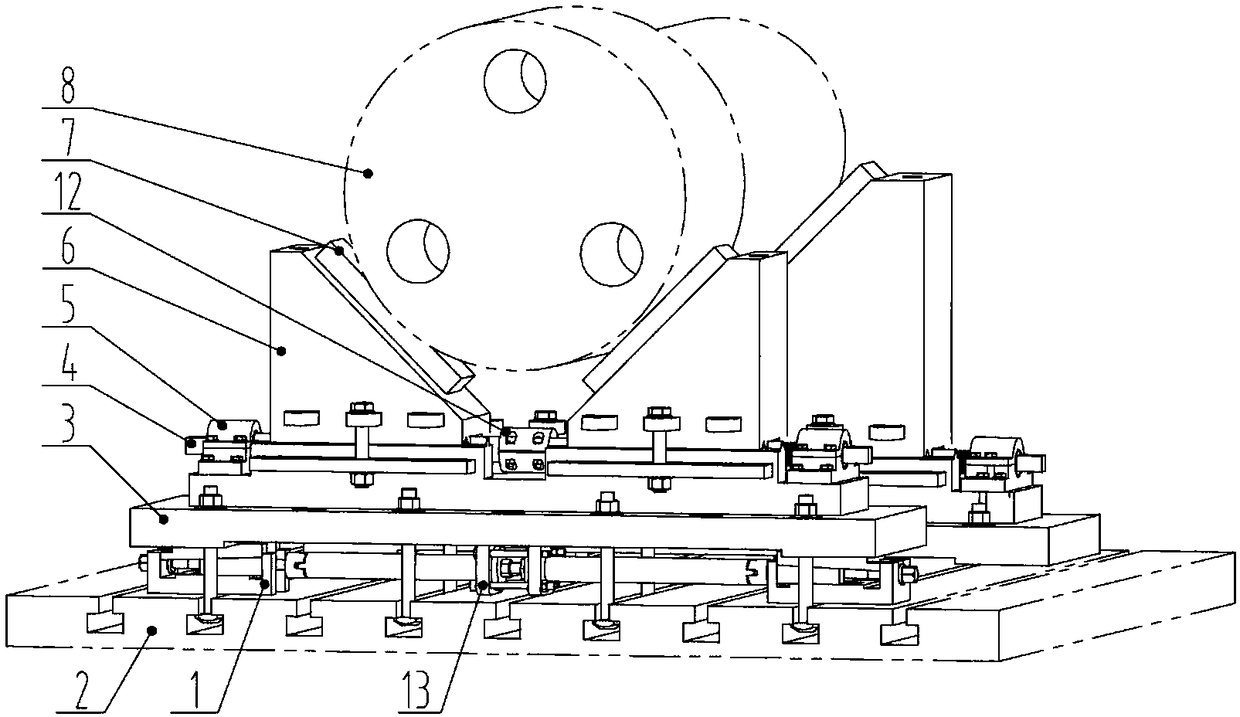

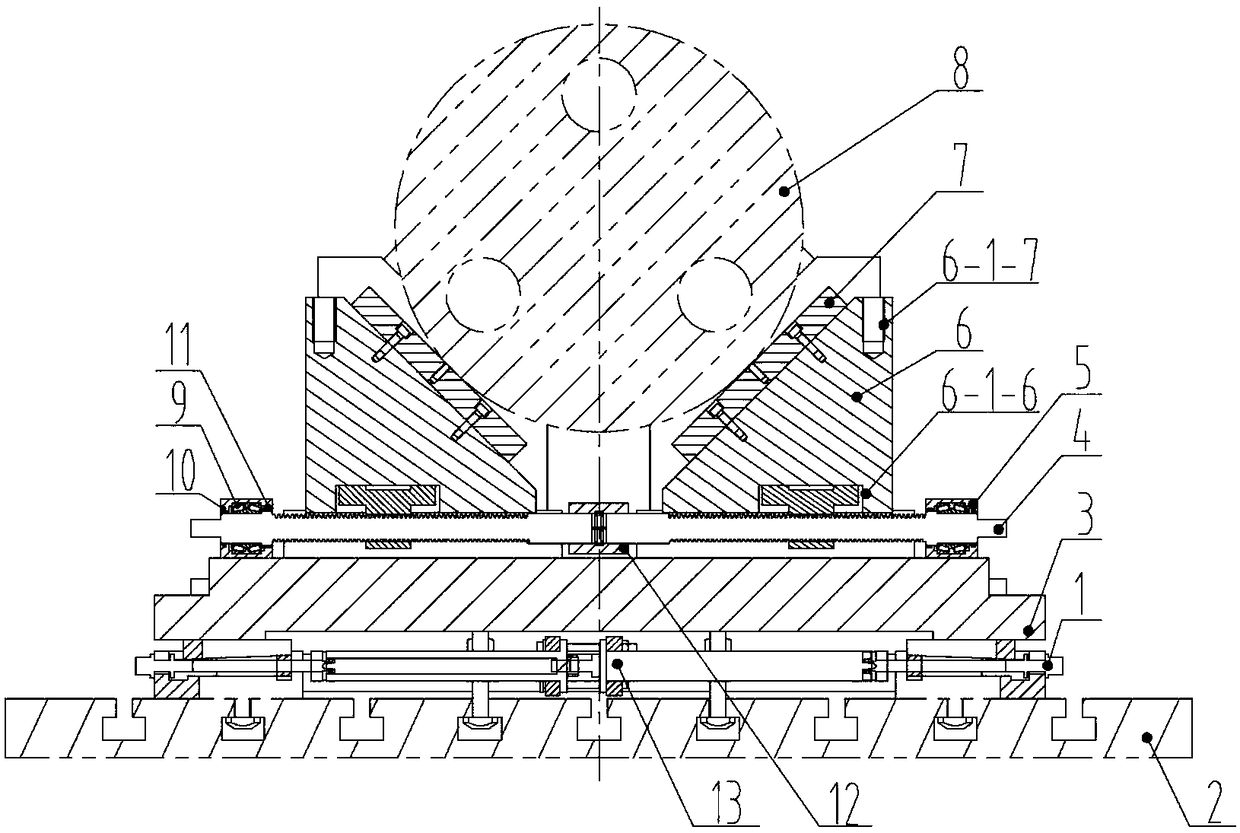

[0035] Such as Figure 1-18 As shown, the high-precision universal adjustable V-shaped positioning tool of this embodiment includes two sets of adjustable pad iron components 1, two bases 3, four sets of slider components 6, four adjusting screws 4, and two sets of clamping shell couplings Device assembly 12, a set of coupling body assembly 13, four fixed pad irons 7, four bearing housing assemblies 5, eight tapered roller bearings 9, four dust-proof seal rings 1 10, four dust-proof seal rings 2 11 and supporting connecting bolts.

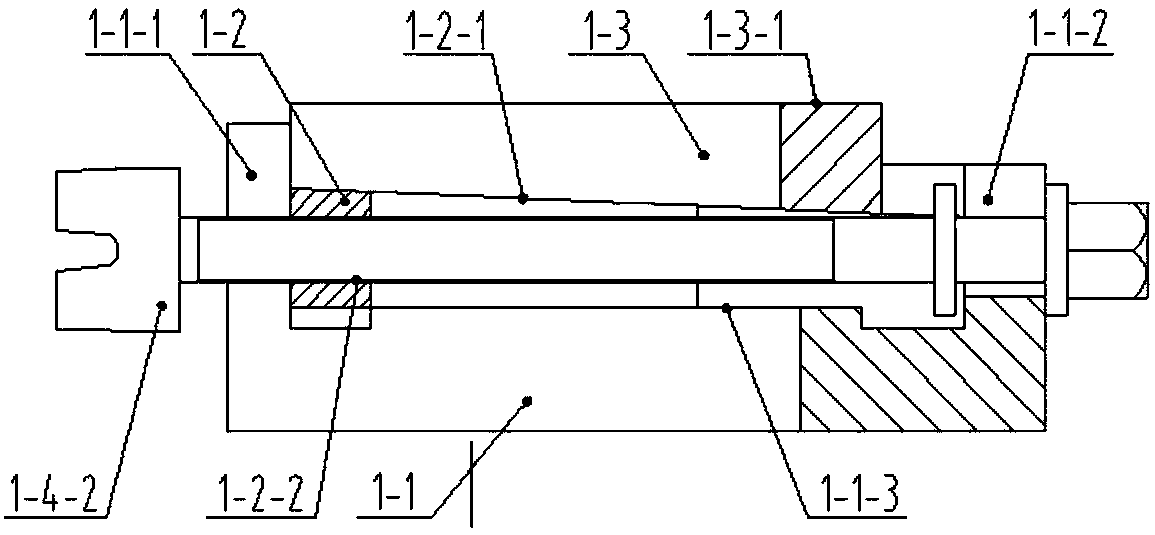

[0036] The adjustable shim assembly 1 includes a lower base 1-1, a middle slide block 1-2, an upper pressing block 1-3 and an adjusting bolt 1-4, and the adjustable shim assembly 1 is symmetrically and movablely placed on the machine table 2. The base 3 is symmetrically provided with four positioning bosses 3-1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com