Rim-suspended chain-spring-vibration absorber compound mechanical-elastic safety wheel structure

A shock absorber, a composite technology, applied in the direction of the wheel hub, vehicle parts, tire parts, etc., can solve the problems affecting the ride comfort of the vehicle, the weakening of the wheel's buffering and vibration reduction ability, etc., and achieve the effect of superior smooth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

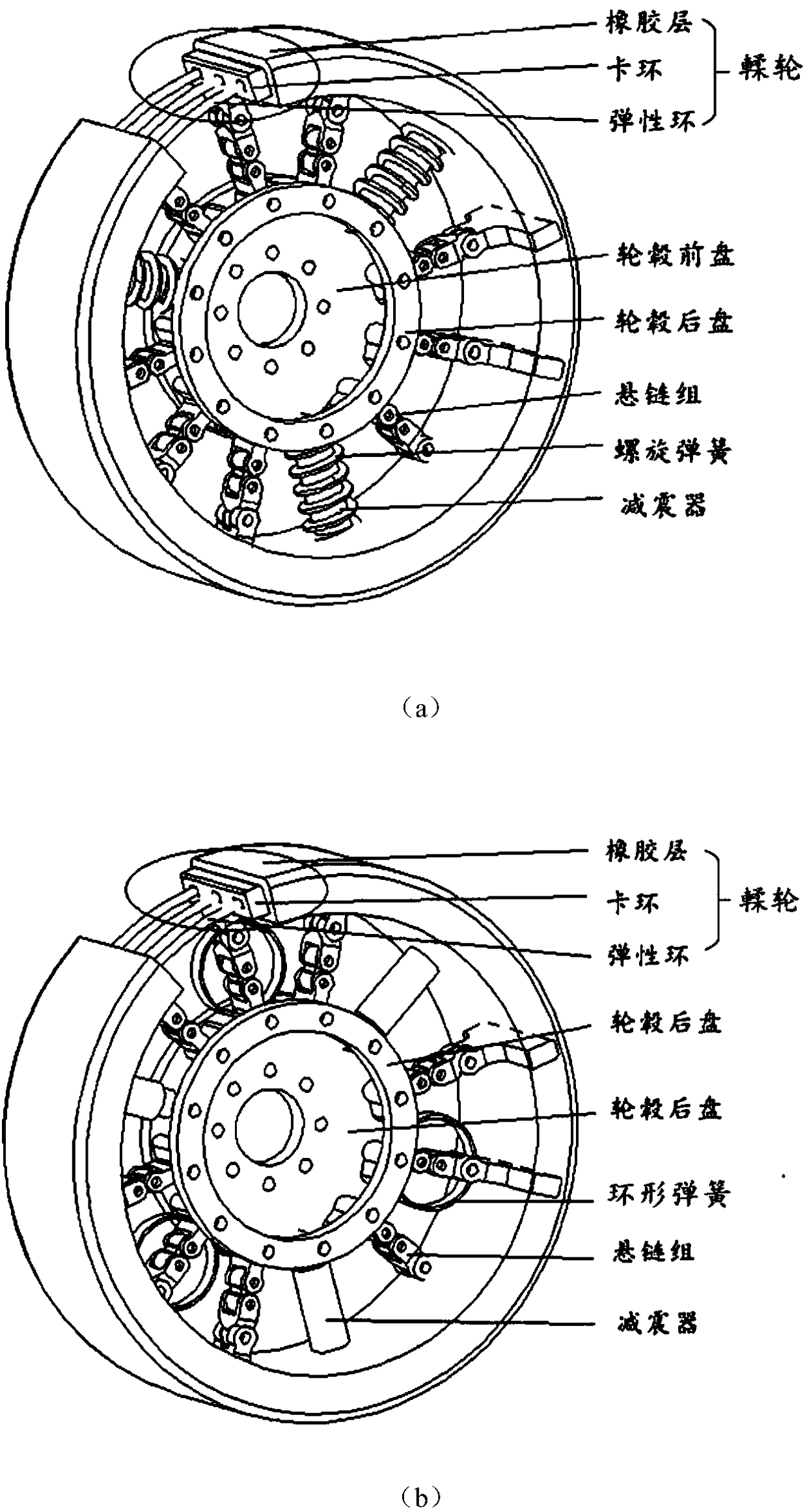

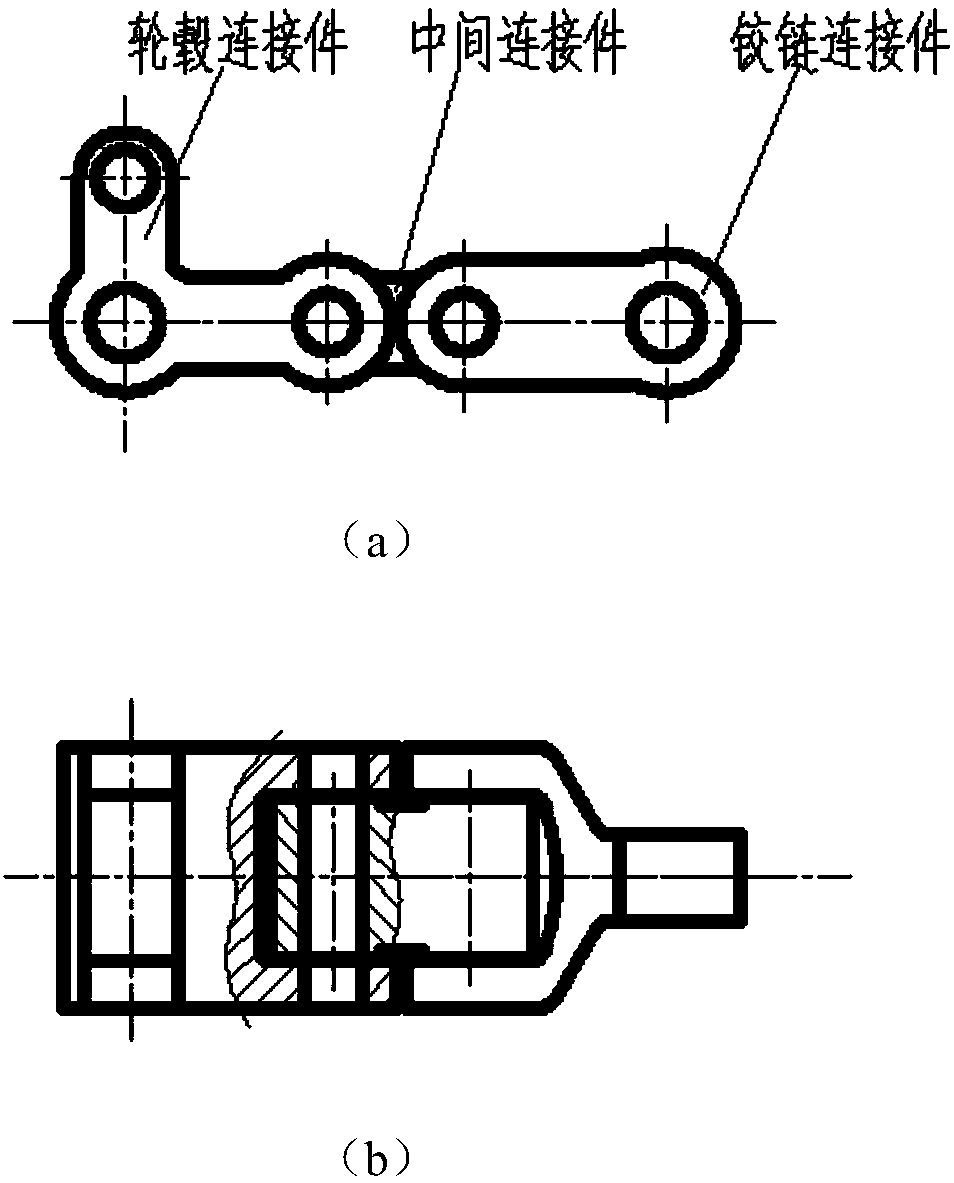

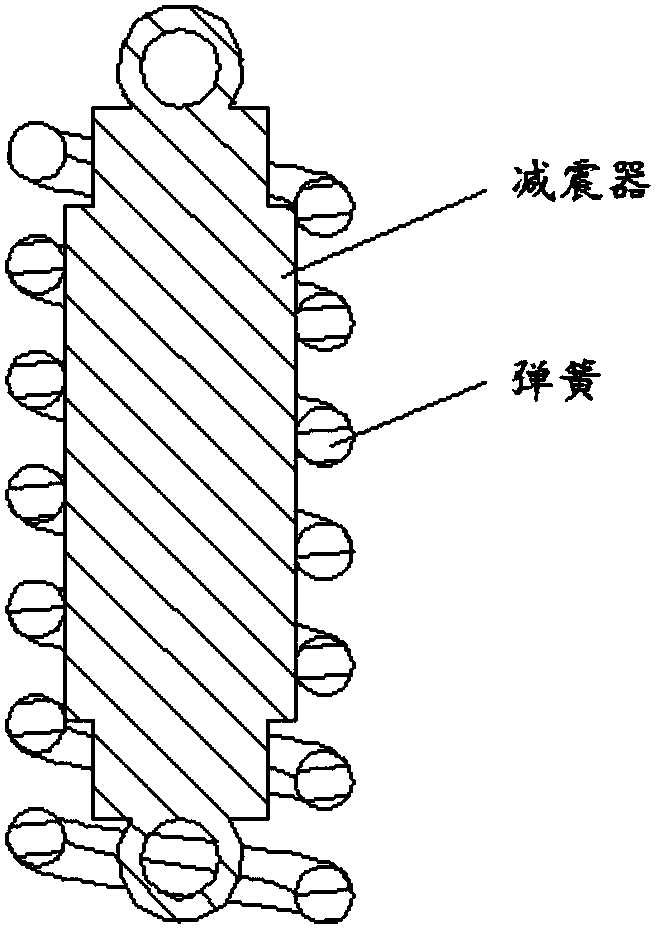

[0027] Such as figure 1 (a) As shown in (b), the present invention discloses a wheel-catenary-spring-shock absorber with multiple buffering and damping functions comprising parts such as a wheel, a catenary, a shock absorber, a spring and a wheel hub Composite mechanical elastic safety wheel structure. The wheel and the hub are connected by a catenary-spring-shock absorber group uniformly distributed in the circumferential direction, and the helical spring is sleeved outside the shock absorber to form a spring-shock absorber group, or a combination of an annular spring and a catenary Constitute a catenary-spring group, the number of catenary chains, springs, and shock absorbers has the same non-1 positive integer greatest common divisor, evenly and alternately distributed between the hub and the wheel in the circumferential direction, and alternately arranged axially symmetrically, during the movement process The four-fold flexible structure of wheel-catenary-spring-shock abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com