Hinged four-wheel drive tractor

An articulated, tractor technology, applied in the direction of control device, transportation and packaging, vehicle parts, etc., can solve the problems of easy damage to the universal joint, the articulated tractor skips gears, and it is difficult to output equal angular velocity, so as to reduce the transmission loss, The effect of compact structure and good drive capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] The present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limitation on the protection scope of the present invention. In addition, according to the description of this document, those skilled in the art can correspondingly combine the features in the embodiments in this document and in different embodiments.

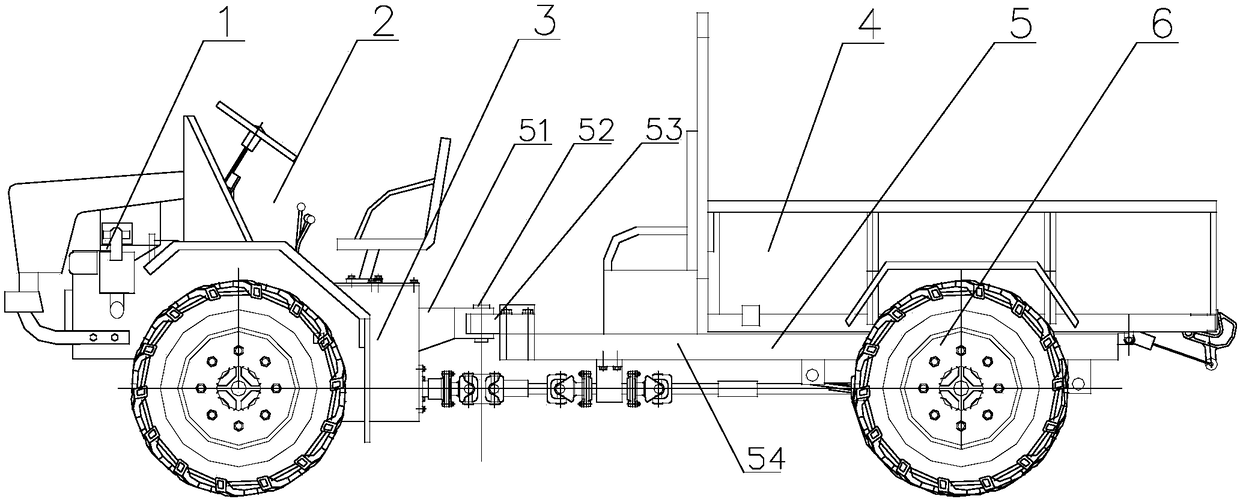

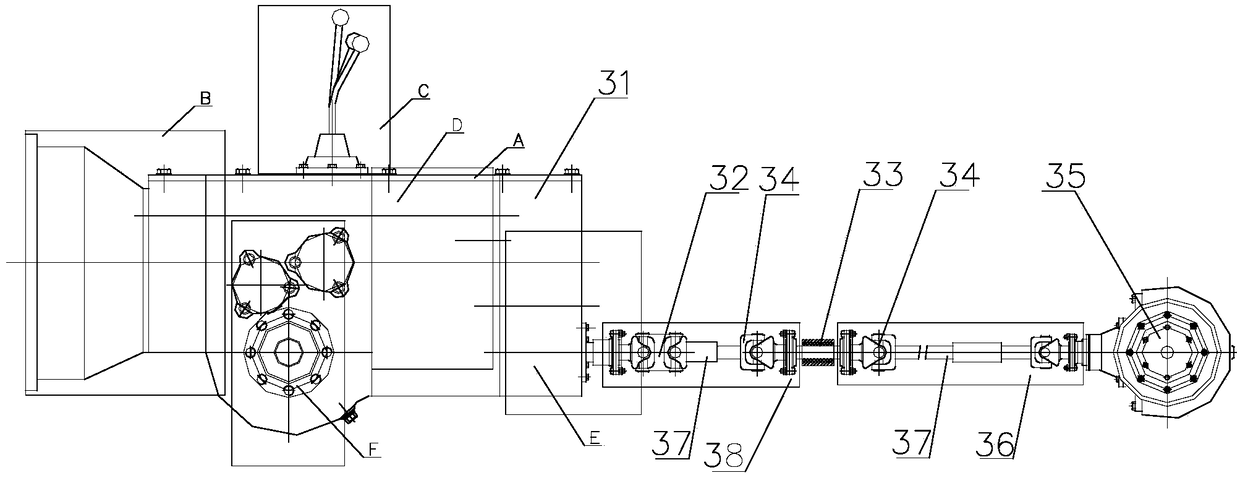

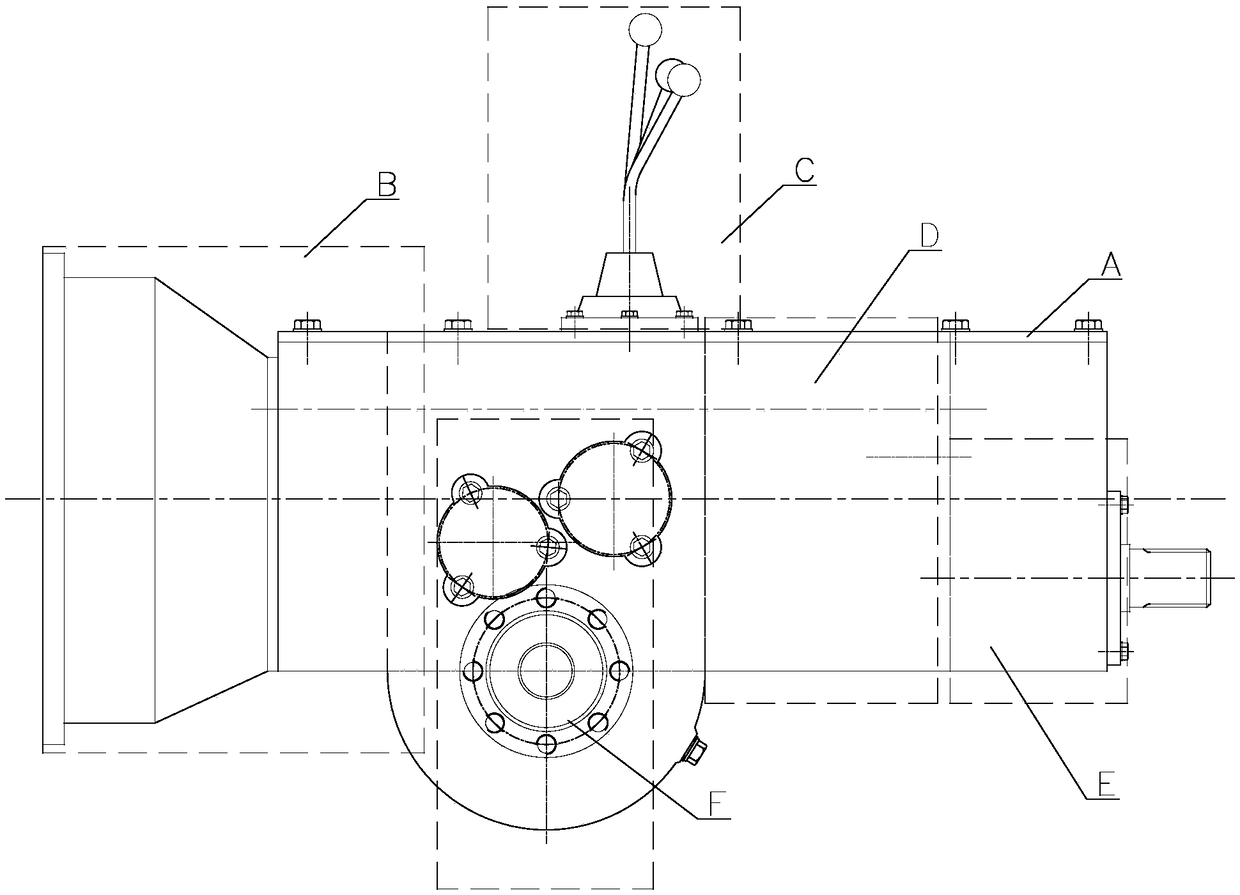

[0104] The embodiment of the present invention is as follows, refer to figure 1 with figure 2 , An articulated four-wheel drive tractor, including an engine 1, a cab 2, a cargo box 4, a frame 5, a driving system 6 and a transmission system 3. The frame 5 includes a traction seat 51, a connecting pin 52, and a traction shaft 53 and frame 54, the transmission system 3 includes a transmission 31, a universal transmission support 33, a rear drive axle 35, a universal transmission rear section 36 and a universal transmission front section 38,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com