Lifting tool for coach roof framework

A skeleton and tooling technology, which is applied in the field of lifting tooling for the roof frame of passenger cars, can solve problems such as damage to the skin surface and failure to ensure safety, and achieve the effects of simple tooling structure, improved transfer efficiency and safety, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

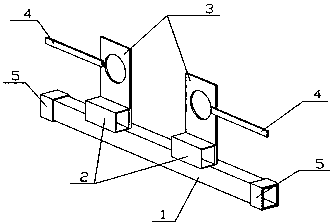

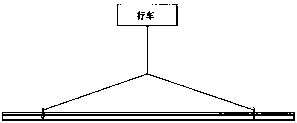

[0011] Structural schematic diagram of the present invention, see figure 1 ; The working schematic diagram of the present invention, see figure 2 .

[0012] As shown in the figure, the adjustable glue nozzle cutter disclosed by the present invention includes: a lower support beam (1) arranged in parallel for supporting and fixing the roof frame, two support blocks (2) welded on the support beam (1), Two support blocks (2) are respectively welded with a support backboard (3) with a round hole, each of the two support backboards (3) is welded with a handle (4), and each end of the support beam (1) is installed with a Anti-slip pads (5).

[0013] Place the two lifting tools of the top frame respectively in the front and rear skylight holes of the top frame, connect the lower support beam (1) with the skylight beam of the top frame, connect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com