Method for identifying bamboo fibers

A technology of bamboo fiber and fiber, which is applied in the field of cellulose fiber identification, can solve the problem of identifying less bamboo fiber, and achieve the effect of sensitive and accurate identification method, which is conducive to accurate identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Activate the cellulose fiber sample to be tested with a sodium hydroxide solution with a concentration of 20wt%. The treatment temperature is 25°C, the treatment time is 2h, and the bath ratio is 1:30. Wash until neutral, and then dry at 105°C for 12 hours to obtain an activated sample, which is sealed and stored for future use.

[0027] (2) Treat the activated sample obtained in step (1) with hydrogen peroxide, a strong oxidizing agent with a content of 5 g / L that does not dissolve cellulose fibers. The treatment temperature is 50 ° C, the treatment time is 1 h, and the bath ratio is 1:45 to obtain oxidized Processed samples.

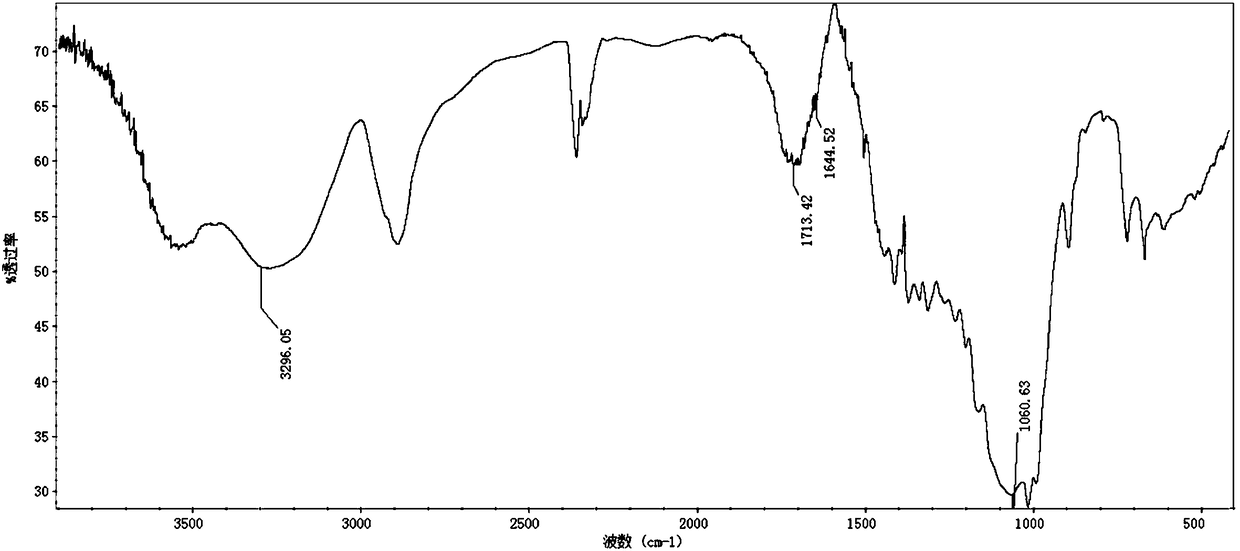

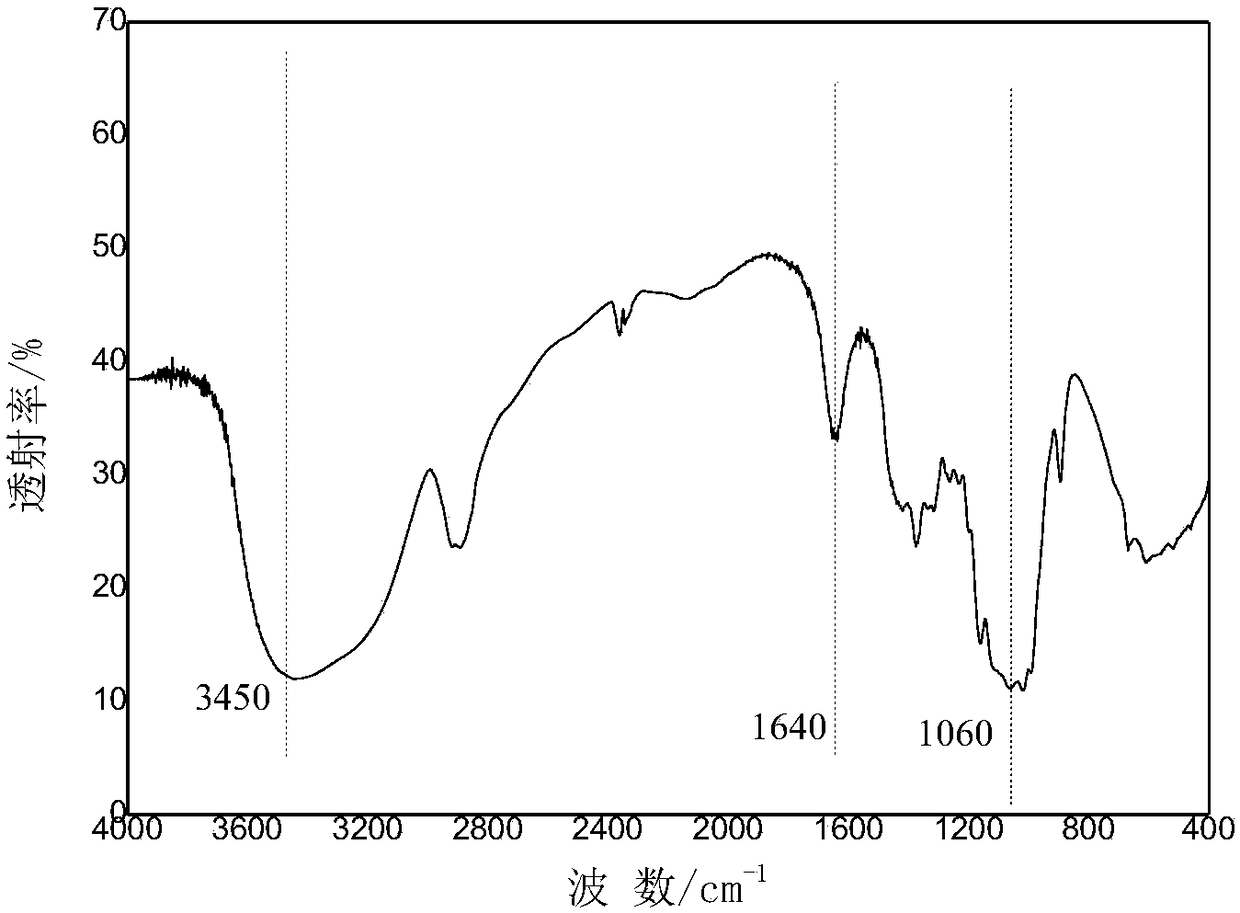

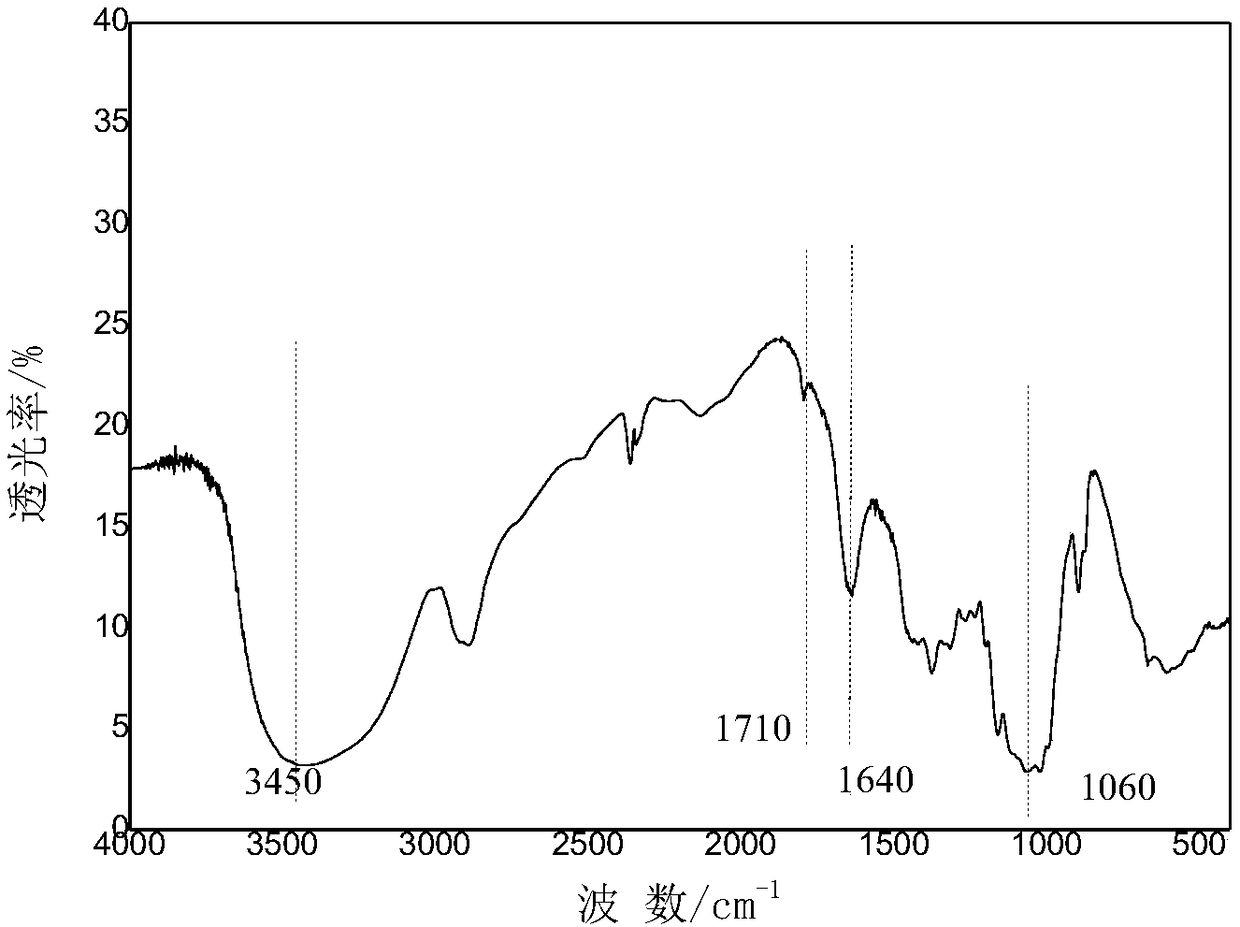

[0028] (3) The oxidized sample obtained in step (2) is made into a sample piece, and the spectral-grade KBr is crushed in an agate mortar and ground to a fine powder, dried in a vacuum oven, and placed in a desiccator for use ;Wash the oxidized sample with water at 80°C to neutral, put it in a vacuum oven and dry it for 16h to dryness; weig...

Embodiment 2

[0031] (1) Activate the cellulose fiber sample to be tested with a sodium hydroxide solution with a concentration of 20wt%. The treatment temperature is 25°C, the treatment time is 2h, and the bath ratio is 1:30. Wash until neutral, and then dry at 105°C for 12 hours to obtain an activated sample, which is sealed and stored for future use.

[0032] (2) Treat the activated sample obtained in step (1) with hydrogen peroxide, a strong oxidizing agent with a content of 5 g / L that does not dissolve cellulose fibers. The treatment temperature is 50 ° C, the treatment time is 1 h, and the bath ratio is 1:45 to obtain oxidized Processed samples.

[0033](3) The oxidized sample obtained in step (2) is made into a sample piece, and the spectral-grade KBr is crushed in an agate mortar and ground to a fine powder, dried in a vacuum oven, and placed in a desiccator for use ;Wash the oxidized sample with water at 80°C to neutral, put it in a vacuum oven and dry it for 16h to dryness; weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com