Protective flange plate structure parameter extraction method

An extraction method and a technology for structural parameters, which are applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of flange weight, etc., and achieve the effect of reducing weight and facilitating on-site application and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

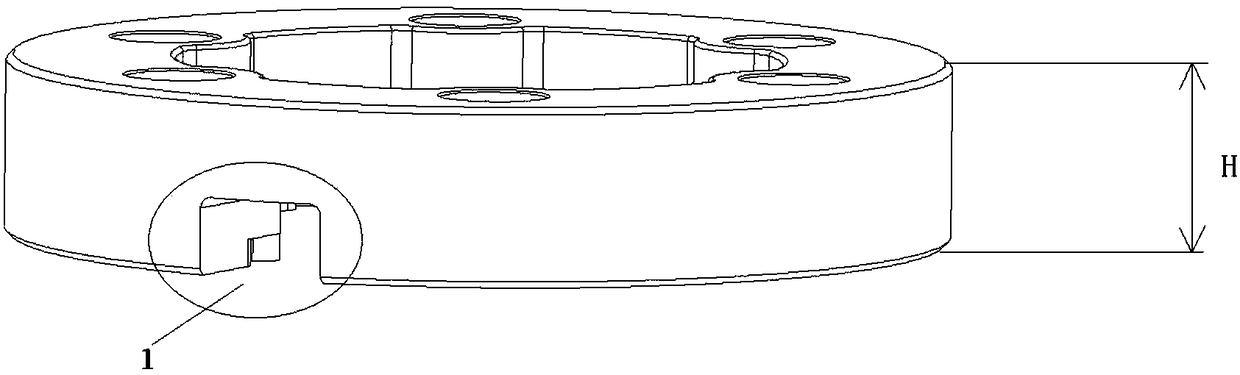

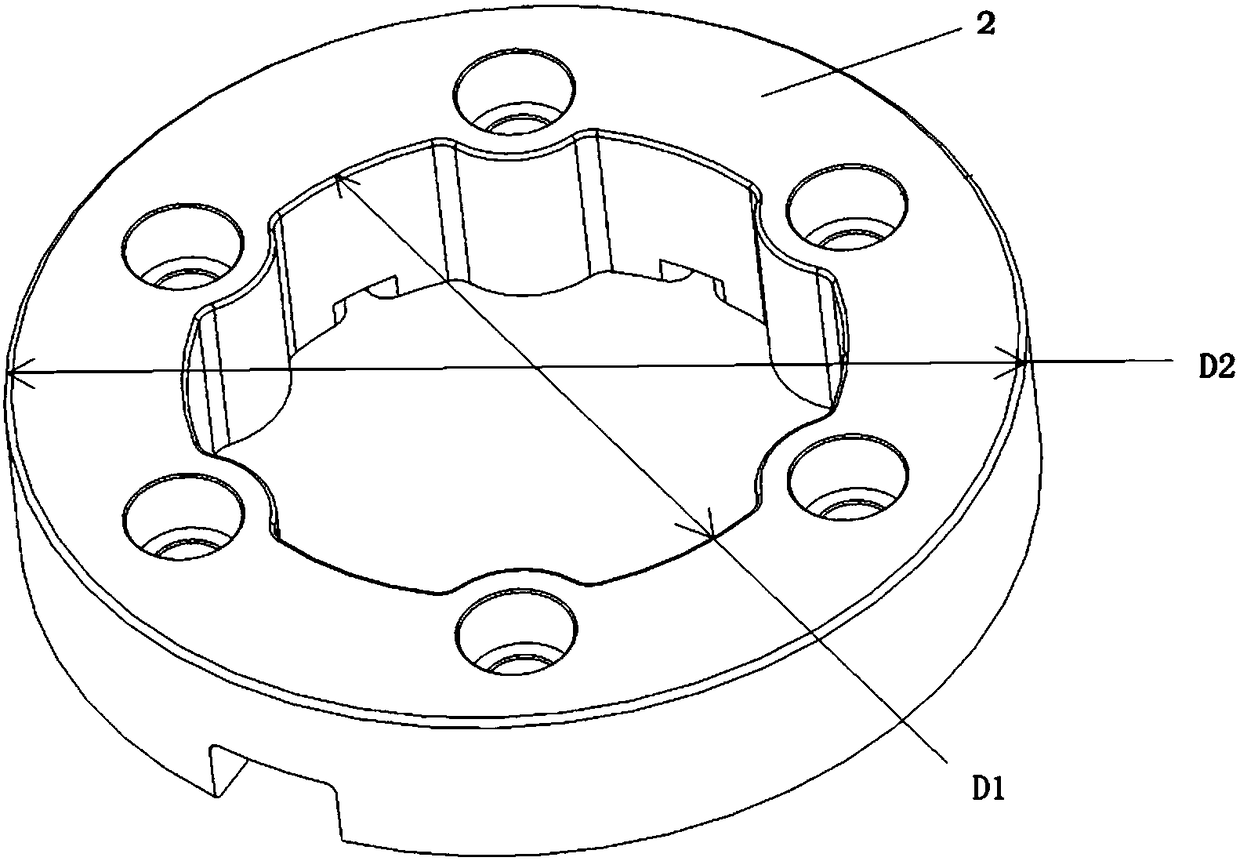

[0028] as attached figure 1 and 2 As shown in the figure, the design object of the present invention is a conformal protective flange 2 for installing a wellhead electronic label reader. The structure of the flange is a hollow circular ring. The bottom surface of the conformal protective flange 2 is processed with electronic Label reader interface installation slot 1, which is a rectangular slot.

[0029] The invention provides a method for extracting structural parameters of a protective flange, and the specific implementation steps of the method are as follows:

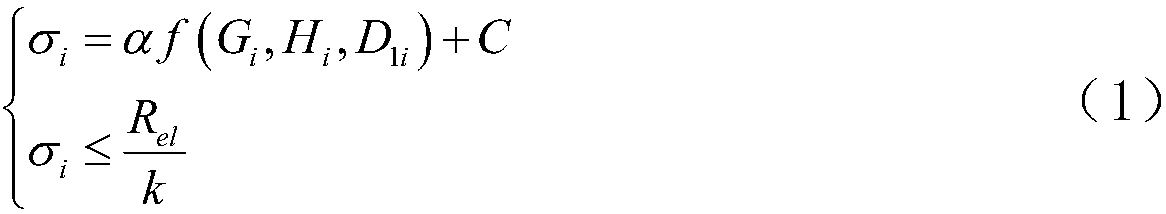

[0030] Step 1, the stress analysis of the flange can be concluded that there are three factors that affect the stress of the flange during the pressure-bearing process: load-bearing G, flange thickness H, flange inner diameter D 1 ; For safety reasons, the stress generated after the flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com