Metal hard film antirust agent and preparing method thereof

A rust inhibitor and hard film technology, applied in the direction of metal material coating process, etc., can solve the problems of increased adhesion, short rust prevention period, harmful to health, etc., and achieves enhanced rust prevention ability, fast coating drying, and easy construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A metal hard film antirust agent, which is synthesized and compounded by petroleum cracking C5 fraction, organic polyol, imidazoline stearic acid quaternary ammonium salt compound, oleic acid triethanolamine, potassium molybdate and sodium pyrophosphate Obtain, it is characterized in that the mass parts of described raw material are as follows:

[0036] Petroleum cracking C5 fraction 10.0;

[0037] Pentaerythritol 4.0;

[0038] 1,2-Propanediol 4.0;

[0039] 12-Hydroxystearic acid imidazoline quaternary ammonium salt 10.0;

[0040] Triethanolamine Oleate 8.0;

[0041] Potassium molybdate 3.0;

[0042] Potassium pyrophosphate 1.0.

[0043] A method for preparing the above-mentioned metal hard film antirust agent, comprising the following steps:

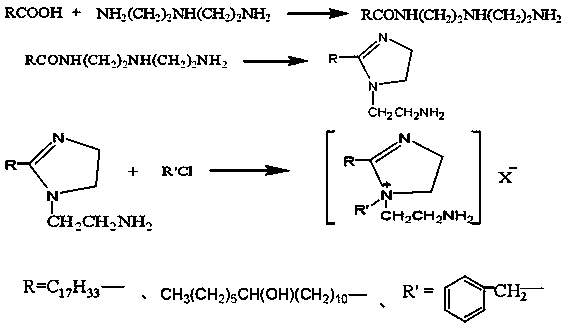

[0044] A, first prepare 12-hydroxystearic acid imidazoline quaternary ammonium salt according to the requirements, first add diethylenetriamine and 12-hydroxystearic acid into the reactor according to the molar ratio of 1.1...

Embodiment 2

[0048] A metal hard film antirust agent, which is synthesized and compounded by petroleum cracking C5 fraction, organic polyol, imidazoline stearic acid quaternary ammonium salt compound, oleic acid triethanolamine, potassium molybdate and sodium pyrophosphate Obtain, it is characterized in that the mass parts of described raw material are as follows:

[0049] Petroleum cracking C5 fraction 12.5;

[0050] Pentaerythritol 8.5;

[0051] 12-Hydroxystearic acid imidazoline quaternary ammonium salt 14.0;

[0052] Triethanolamine Oleate 10.5;

[0053] Potassium molybdate 3.8;

[0054] Potassium pyrophosphate 1.5.

[0055] Its preparation method etc. are the same as embodiment 1.

Embodiment 3

[0057]A metal hard film antirust agent, which is synthesized and compounded by petroleum cracking C5 fraction, organic polyol, imidazoline stearic acid quaternary ammonium salt compound, oleic acid triethanolamine, potassium molybdate and sodium pyrophosphate Obtain, it is characterized in that, the mass parts of described raw material is as follows:

[0058] Petroleum cracking C5 fraction 15.0;

[0059] Pentaerythritol 3.0;

[0060] 1,3-Propanediol 3.0;

[0061] Glycerol 3.0;

[0062] 12-Hydroxystearic acid imidazoline quaternary ammonium salt 18.5;

[0063] Triethanolamine Oleate 13.0;

[0064] Potassium molybdate 4.5;

[0065] Potassium pyrophosphate 2.0.

[0066] Its preparation method etc. are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com