A lithium-sulfur battery diaphragm and preparation method thereof

A lithium-sulfur battery and diaphragm technology, applied in the field of lithium-sulfur battery diaphragm and its preparation, can solve the problems of poor mechanical strength and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

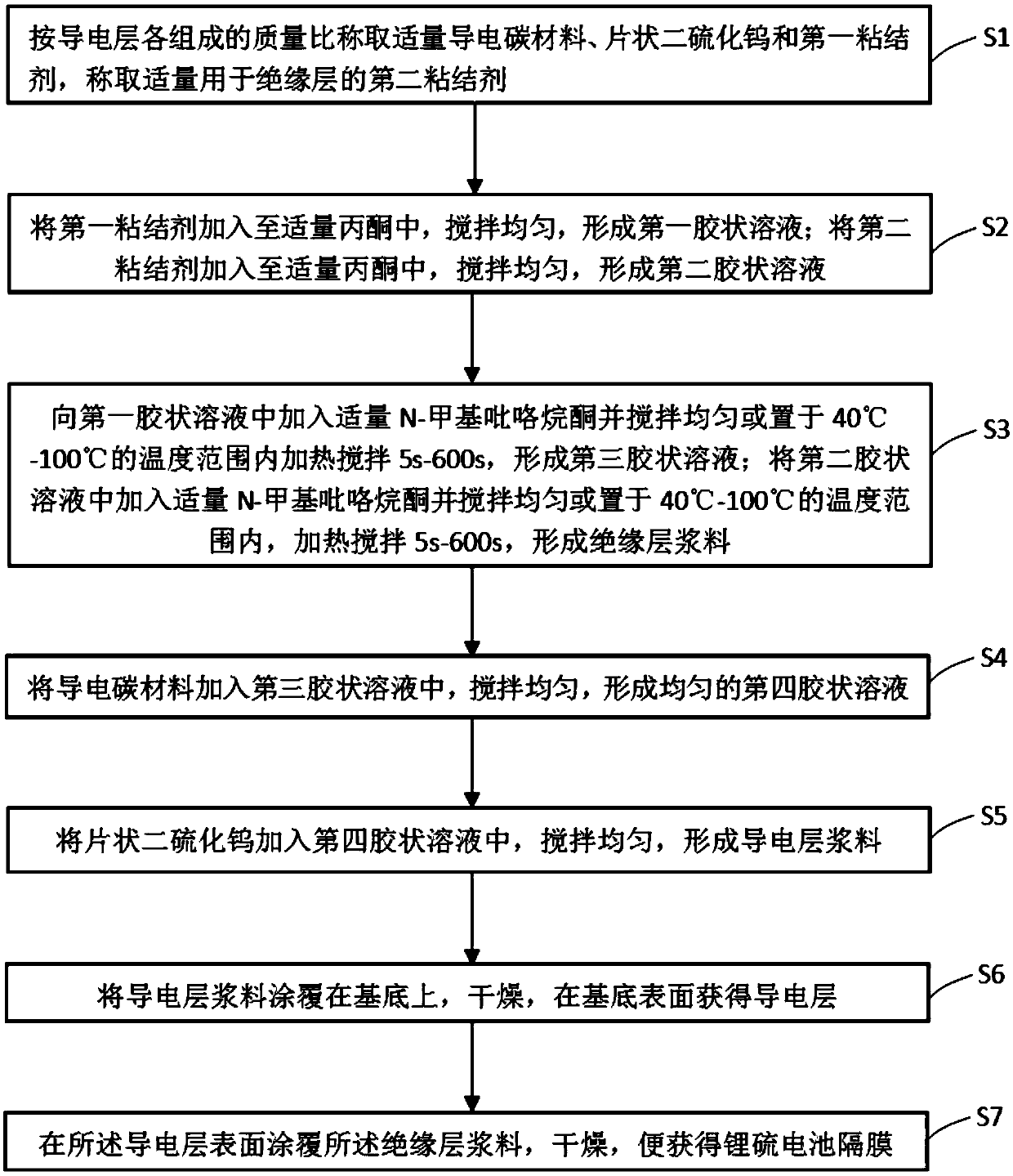

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] The invention provides a separator for a lithium-sulfur battery, comprising: a conductive layer and an insulating layer arranged on one side of the conductive layer. The composition of described conductive layer is:

[0041] Conductive carbon material 20wt%,

[0042] Flake tungsten disulfide 10wt%,

[0043] The first binder is 70wt%.

[0044] The composition of the insulating layer is: the second binder.

[0045] The conductive carbon material is super-p.

[0046] Both the first binder and the second binder are PVDF-HFP.

[0047] The thickness of the conductive layer is 20um, and the thickness of the insulating layer is 10um.

[0048] The particle size range of the conductive carbon material is: 0.01um-1um, the particle size range of the flaky tungsten disulfide is: 0.1um-10um, and the specific surface range is: 5m 2 / g-110m 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com