Transcatheter cardiac valve pre-assembly system and pre-assembly method

A heart valve and catheter technology, applied in the field of transcatheter heart valve preinstallation system, can solve the problems of valve leaflet deformation, affecting the normal function and service life of the valve, damage, etc., to prevent irreversible deformation or damage, prolong service life, Guarantee the effect of normal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

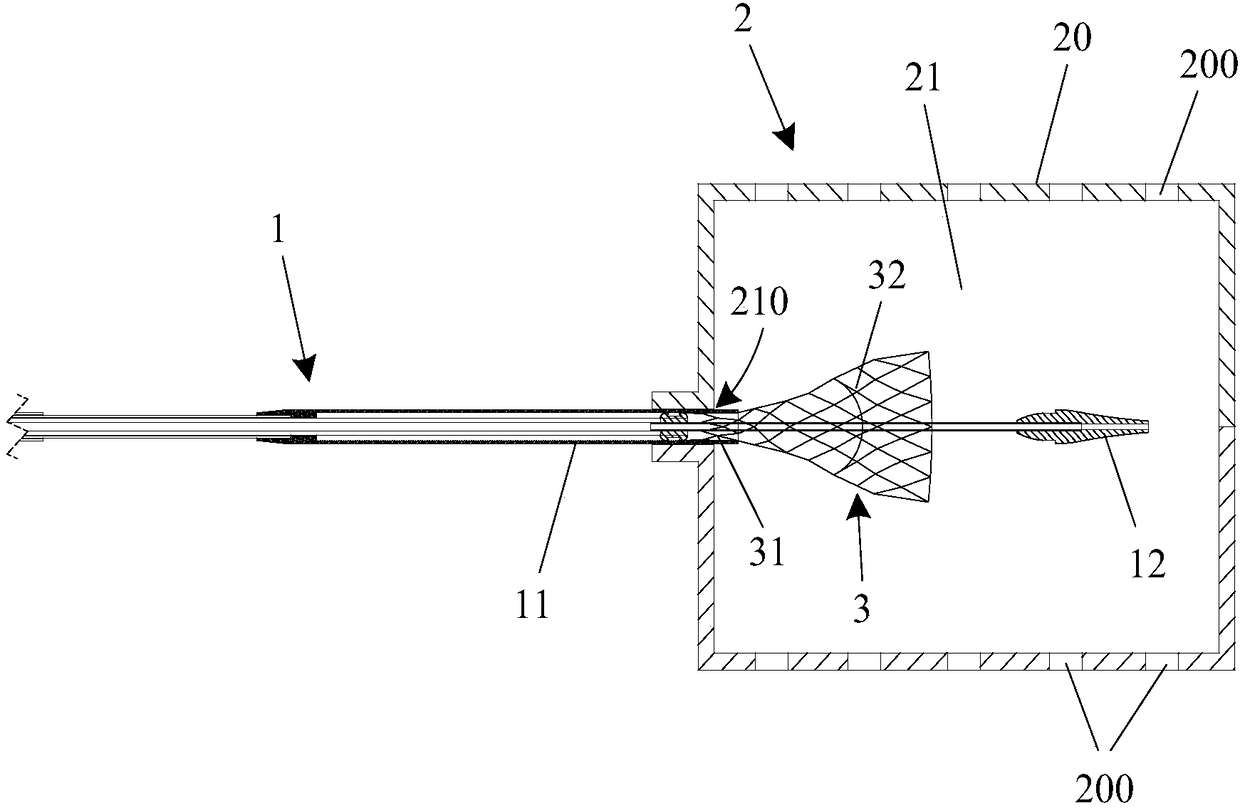

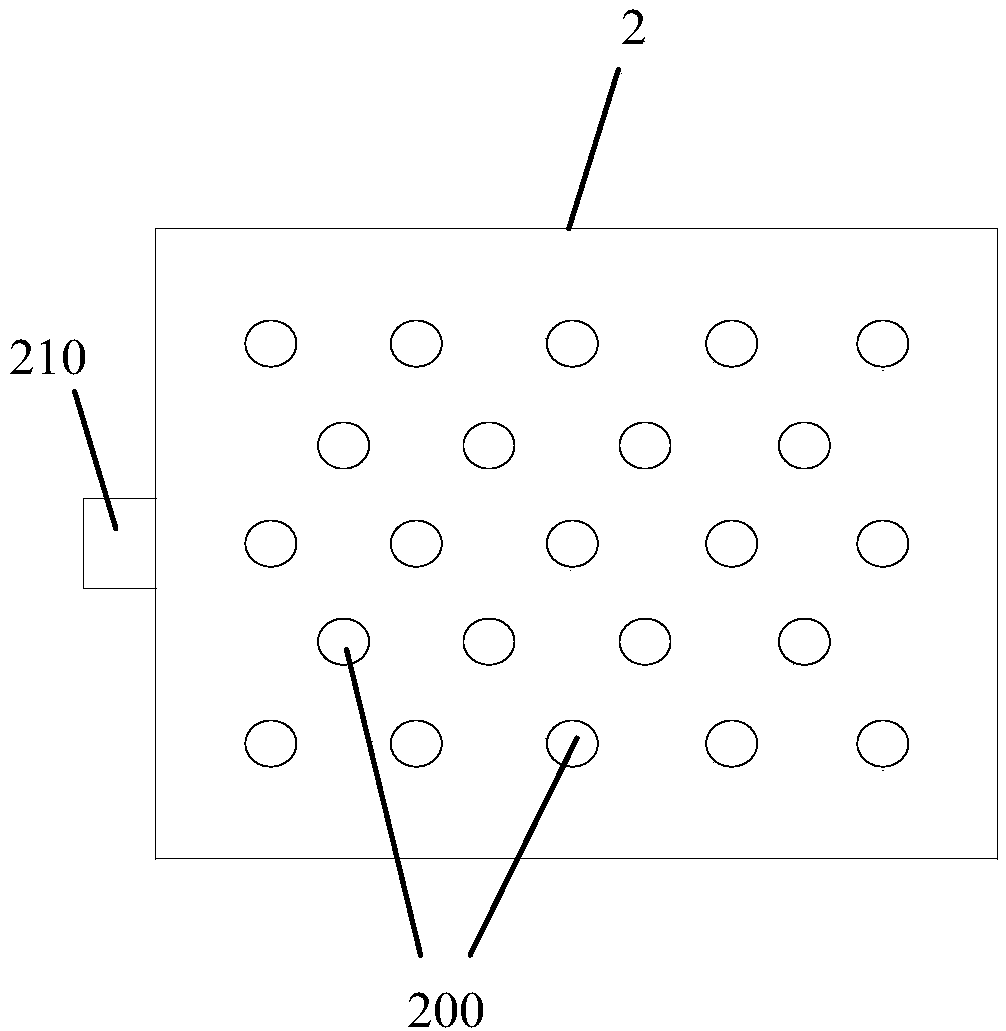

[0058] figure 1 It is a schematic structural diagram of a valve installed in the transcatheter heart valve preinstallation system provided by Embodiment 1 of the present invention. figure 2 It is a side structural view of the protective device of the transcatheter heart valve preinstallation system provided by Embodiment 1 of the present invention. refer to Figure 1 to Figure 2 As shown, the present embodiment provides a transcatheter heart valve preinstallation system.

[0059] The transcatheter heart valve preinstallation system includes: a delivery system 1, the delivery system 1 includes a catheter 11 for installing the valve 3 and an operating handle (not shown in the figure). Wherein, the catheter 11 can realize the delivery of the valve 3 in the human body. In order to reduce the damage to blood vessels during the process of implanting the valve 3 into the human body. The smaller the diameter of the catheter 11 the better, generally smaller than the inner diameter...

Embodiment 2

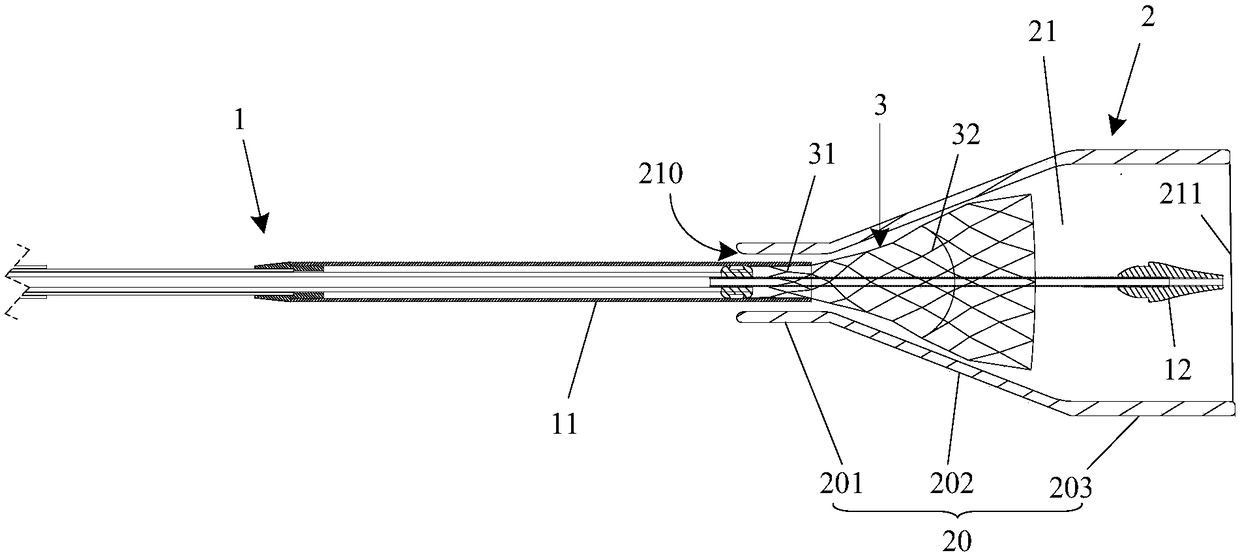

[0080] image 3 It is a schematic structural diagram of a valve installed in the transcatheter heart valve preinstallation system provided by Embodiment 2 of the present invention. refer to image 3 As shown, this embodiment provides a structural schematic diagram of a transcatheter heart valve preinstallation system with another structure. The difference between this embodiment and the first embodiment lies in the specific shape of the protective device 2 .

[0081] In this embodiment, the protective cylinder 20 specifically includes: a first cylindrical section 201 , a conical section 202 and a second cylindrical section 203 sequentially connected from the proximal end of the protective cylinder 20 to the distal end of the protective cylinder 20 . Wherein, the inner diameter of the first cylindrical section 201 is smaller than the inner diameter of the second cylindrical section 203 , and the inner diameter of the tapered section 202 gradually increases from an end close t...

Embodiment 3

[0087] Figure 4 A schematic structural diagram of a valve installed in the transcatheter heart valve preinstallation system provided by Embodiment 3 of the present invention. Figure 5 The three-dimensional structure diagram of the protective device in the transcatheter heart valve preinstallation system provided by the third embodiment of the present invention. Figure 6 A side view structural view of the protective device in the transcatheter heart valve preinstallation system provided by Embodiment 3 of the present invention. Figure 7 A side sectional view of the protective device in the transcatheter heart valve preinstallation system provided by Embodiment 3 of the present invention. Figure 8 A schematic structural diagram of the first locking member in the protective device of the transcatheter heart valve preinstallation system provided by Embodiment 3 of the present invention. Figure 9 A side sectional view of the first locking member in the protective device of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com