Anti-freezing wearing layer and maintenance construction method of asphalt pavement

A technology of asphalt pavement and construction method, which is applied in the direction of coagulation pavement paved on site, roads, roads, etc., to achieve the effects of ensuring stability, reducing costs, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

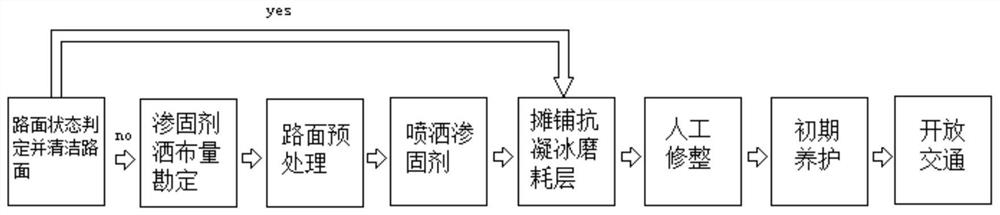

Method used

Image

Examples

Embodiment 1

[0059] The road surface of the present embodiment is not good, the road surface layer is aging, the asphalt softening point is increased by 8 ° C, the needle is 65% of the new paved asphalt, so the anti-codble wear layer is added Pre-spraying the perfiltration agent.

[0060] The anticoagulant wear layer of the present embodiment is formulated from the following weight ratio of the raw material mixed: anti-coagulation ice abrasive layer special assembly 85%; anti-coagulation wear layer dedicated emulsified asphalt 15%.

[0061] Among them, the anti-codble wear layer special assembly is mixed by the following weight ratio of raw materials: basalt, 85%; temperature-sensitive anticoagulant 5%, model is inner dicing antifreeze, using temperature sensing nanomaterials to ordinary The salt anticoochastic anticogenic acid is made of coating, thereby achieving anti-condensive ice with different release rates, thereby extending the use period, and relatively low in cost; 1% of the filler, ...

Embodiment 2

[0092] The road surface of the present embodiment is not good in survey, and the pavement surface is leaned, and the asphalt aging is severe. The original road surface asphalt is delayed at 10 ° C. The softening point is 10 ° C, which is increased by 10 ° C. Pre-spraying agent is sprayed before the ice cohesial wear layer.

[0093] The maintenance construction method of the anticoagulant wear layer asphalt pavement of the present embodiment is substantially the same, and the difference is that the anticoagulant abrasive layer and the formulation of the percolator employed are different.

[0094] The anticoagulant ice abrasive layer of the present embodiment is formulated from the following weight ratio of raw materials: 88% special assembly of anti-coagulation wear layer; 12% of the anticoagulant abrasive layer dedicated to 12%.

[0095] Among them, the anti-codble wear layer special collector is mixed by the following weight ratio of raw materials: 90% basal; 3% of the temperature-...

Embodiment 3

[0099] The road surface of the present embodiment is not good to survey. Although the road surface layer asphalt is slightly aging, there is a capillary crack in the road surface, so it is necessary to spray the permeability prevention agent before adding the anti-codble wear layer.

[0100] The maintenance construction method of the anticoagulant wear layer asphalt pavement of the present embodiment is substantially the same, and the difference is that the anticoagulant abrasive layer and the formulation of the percolator employed are different.

[0101] The anticoagulant wear layer of the present embodiment is formulated from the following weight ratio of the raw material mixture: 92% of the anticoagulant wear layer dedicated; anti-coagulating abrasive layer special emulsified asphalt 8%.

[0102] Among them, the anti-codble wear layer special collector is mixed by the following weight ratio of raw material: 95% basal; temperature-sensing anticoagulant 1%, model is inner dicing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com