A kind of fireproof coating for steel structure surface and its application

A technology for fire-resistant coatings and steel structures, applied in fire-resistant coatings, anti-corrosion coatings, coatings, etc., can solve problems such as poor appearance, fire-resistant coatings on platform canopy columns, and potential safety hazards, achieving low solubility and improving fire protection. effect, the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The anti-freezing ultra-thin finish type fireproof coating of the present embodiment consists of the following components by weight: 12 parts of fluorosilicone emulsion (SD-5681), 35 parts of silicon acrylic emulsion (SD-528), 2 parts of fire retardant (Aluminum phenyl hypophosphite), 12 parts of carbon forming agent (expandable graphite), 15 parts of foaming agent (melamine resin coated ammonium polyphosphate (MF-APP)), 3 parts of 48# industrial grade white oil, filler 8 parts (5 parts of R-902 titanium dioxide, 1 part of KPore-G200 nano airgel powder, 2 parts of 1250 mesh 5S calcined kaolin), 10 parts of rust inhibitor (APW-I aluminum tripolyphosphate), 1 part of additive ( 0.4 part of NC polyphosphate sodium salt dispersant, 0.1 part of DH-202 defoamer, 0.5 part of RHEOLATE299 water-based rheological additive), 0.5 part of antibacterial agent (DEUADD MB-11 water-based preservative), 0.5 part of pH regulator (DEUADD MA-95pH regulator), 1 part of refractory fiber (ba...

Embodiment 2 to 6 and comparative example 1 to 5

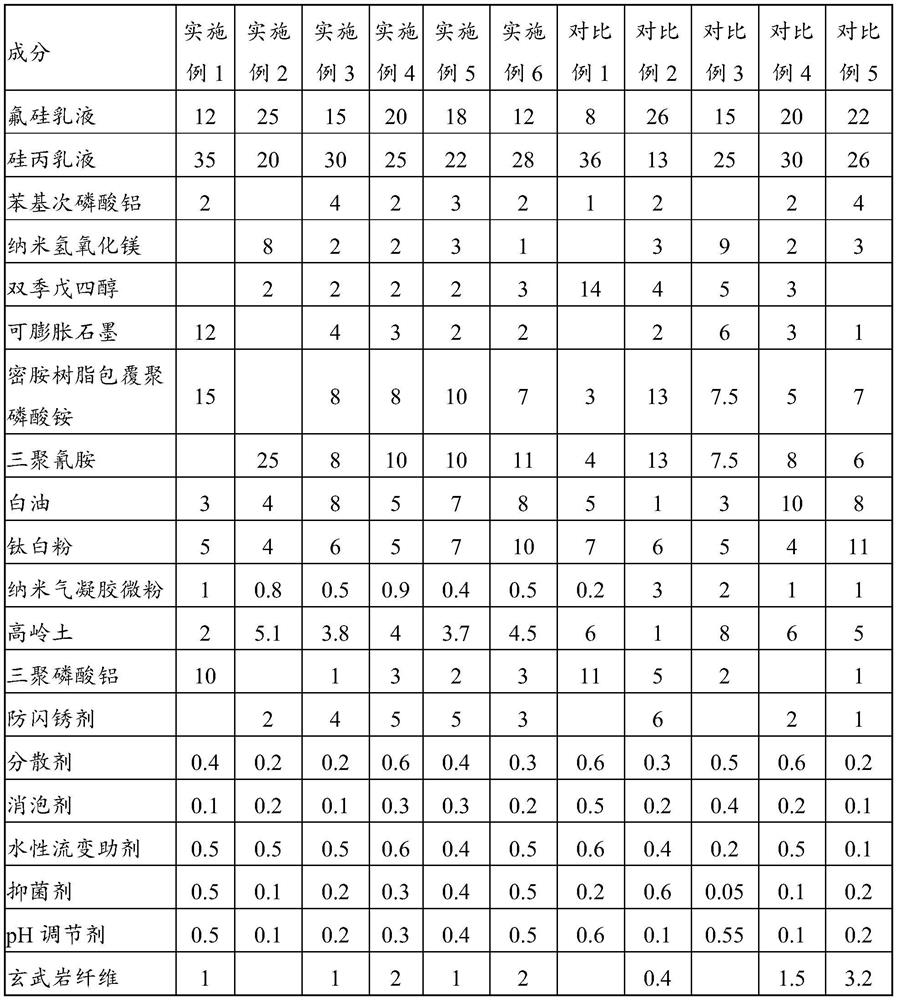

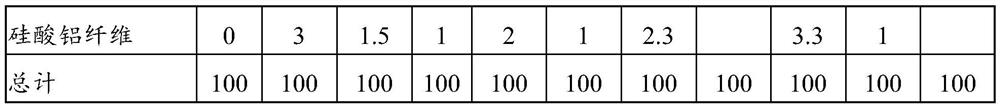

[0040] Examples 2 to 6 and Comparative Examples 1 to 5 were all prepared according to the preparation method in Example 1, and the specific raw material composition ratios are shown in Table 1. Among them, the anti-flash rust agent is SC2190Z anti-flash rust agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com