Copolymer, preparation method thereof, antistatic agent containing copolymer, and application of antistatic agent

A technology of copolymers and derivatives, used in fuel additives, liquid carbon-containing fuels, fuels, etc., can solve the problems of substandard water separation index, environmental pollution, and little production and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

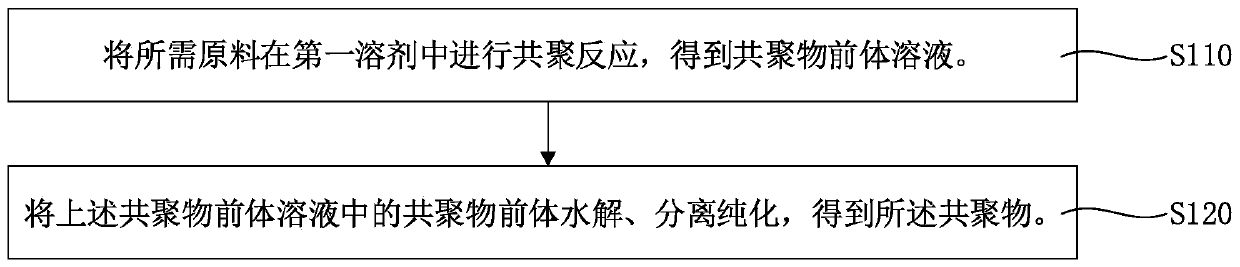

[0038] Such as figure 1 Shown, the preparation method of the copolymer of one embodiment, comprises the following steps:

[0039] Step S110: Copolymerize the raw materials in the first solvent to obtain a copolymer precursor solution.

[0040] The raw materials in the above step S110 include maleic acid derivatives, carboxylic acid enester compounds, acrylamide compounds, ethylene and α-olefins, the above-mentioned maleic acid derivatives, carboxylic acid enester compounds, acrylamide compounds The molar ratio of ethylene and α-olefin is 1: (0~5): (0~5): (15~30): (5~15); above-mentioned maleic acid derivative is by maleic anhydride and amines The compound is reacted, the amine compound is selected from one of dibasic amines and alcohol amines, and the number of carbon atoms of the amine compound is 3 to 18; the above-mentioned carboxylic acid enester compound is selected from vinyl formate, propylene formate At least one of ester, vinyl acetate, propylene acetate, 3-butenyl ...

Embodiment 1

[0068] The preparation process of the antistatic agent of the present embodiment is as follows:

[0069] 1. Preparation of copolymer

[0070] (1) Add 0.1mol maleic anhydride and xylene (equal to the total mass of the reaction raw materials in this step) into the reactor, heat to dissolve, add a mol of amine compound A (abbreviated as A in Table 1), continue Heating to 90°C, acylation reaction for 4 hours, and desolvation to obtain maleic acid derivatives.

[0071] (2) Add the above-mentioned maleic acid derivatives, ethylene and 1-nonene at a molar ratio of 1:15:5 in xylene (equal to the total mass of the reaction raw materials in this step), and heat to At 45°C, add 0.2% azobisisobutyronitrile based on the total mass of the reaction raw materials, continue heating to 90°C, and react for 5 hours to obtain a copolymer precursor solution.

[0072] (3) Add an aqueous sodium hydroxide solution with a mass fraction of 15%, heat to 70° C. for hydrolysis for 30 minutes, then neutra...

Embodiment 2

[0084] 1. Preparation of copolymer

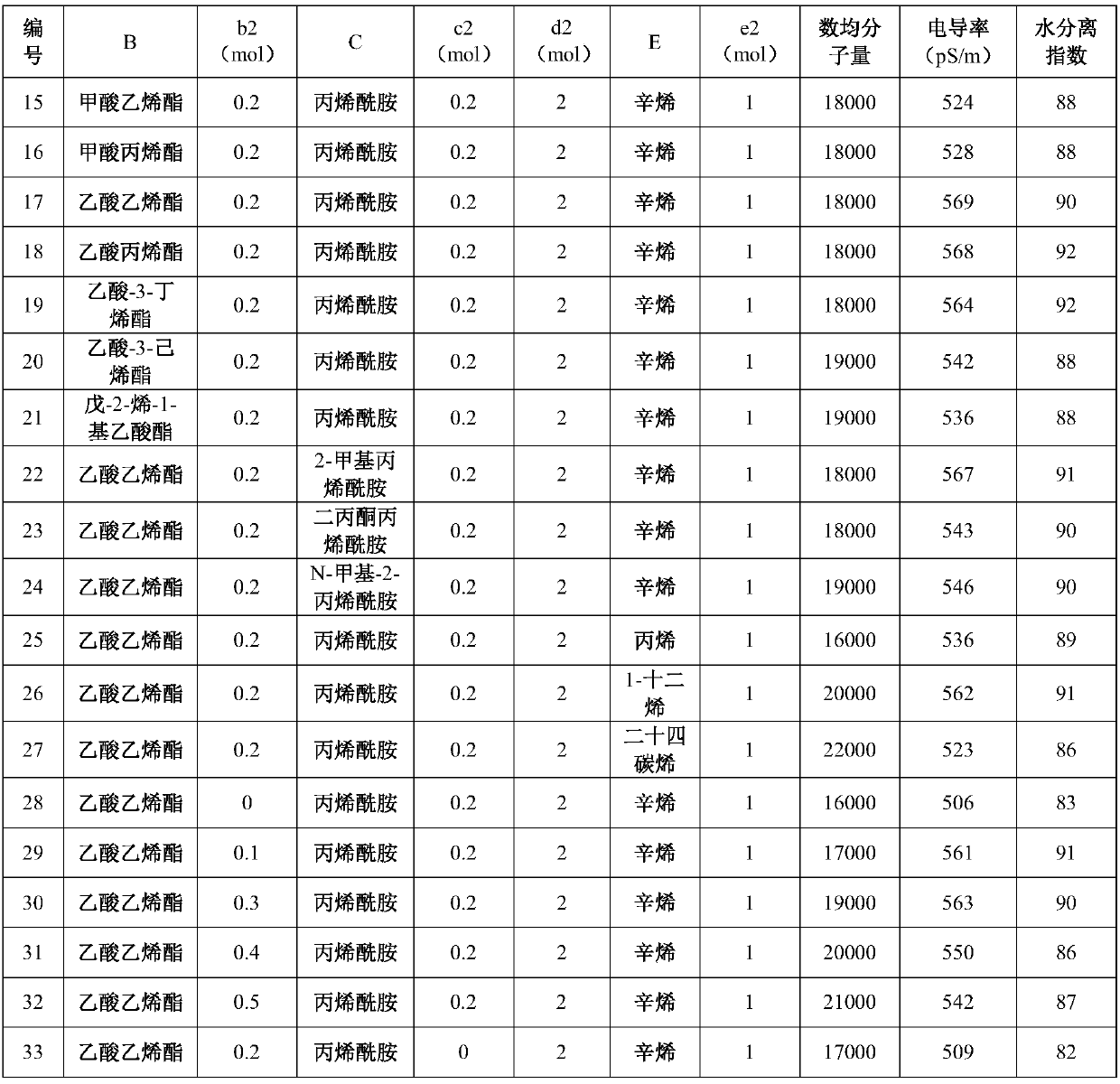

[0085] (1) The maleic acid derivative corresponding to antistatic agent #3 in 0.1mol embodiment 1, b2 mol carboxylate enyl compound B (abbreviated as B in Table 2), c2 mol acrylamide compound C (table 2 (referred to as C), d2 mol ethylene, e2 mol α-olefin (referred to as E in Table 2) were dissolved in trimethylbenzene (equal to the total mass of the reaction raw materials in this step), heated to 45°C under nitrogen protection, and added 0.3% dibenzoyl peroxide of the total mass of the reaction raw materials, continue to heat up to 100 ° C, and react for 3 hours to obtain a copolymer precursor solution;

[0086] (2) Add an aqueous sodium hydroxide solution with a mass fraction of 20%, heat up to 60° C. for hydrolysis for 50 minutes, then neutralize, wash with water, dry, and remove solvent to obtain a copolymer.

[0087] 2. Preparation of antistatic agent

[0088] Take 25 parts of the copolymer prepared above, 15 parts of stearamidoethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com