Plate bumping type processing method and device for metal silicon powder

A technology of metal silicon powder and a processing method, which is applied in the processing field of silicon powder, can solve the problems such as the inability of equipment to produce and output qualified products, the high requirements for wear-resistant materials of the pulverizer, and the difficulty in controlling the total amount of fine powder. The effect of promotion, simple and reasonable structure and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

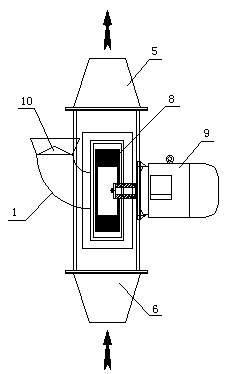

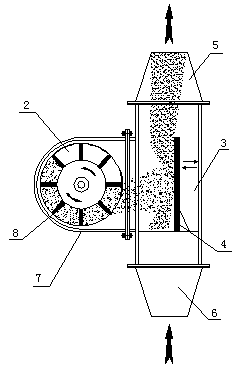

[0023] Embodiment one: see figure 1 and figure 2 , in the figure, 1-feed inlet, 2-impeller type material rejection mechanism, 3-cylindrical crushing chamber, 4-wear-resistant impact plate, 5-upper half, 6-lower half, 7-impeller shell, 8-impeller, 9-motor, 10-conical distributor.

[0024] The metal silicon powder processing device mainly includes an elbow-shaped feed inlet 1 and an impeller-type material rejection mechanism 2. The material rejection mechanism 2 is connected with a cylindrical crushing chamber 3, and a wear-resistant impact plate 4 is arranged in the middle of the crushing chamber 3. The upper half 5 and the lower half 6 of the cylindrical crushing chamber 3 are connected by vertebral bodies and have an opening. The upper half 5 is connected with the fan, and the lower half 6 is an air inlet. The material throwing mechanism 2 is made up of parts such as impeller casing 7, impeller 8, motor 9, elbow shape feed inlet 1. One side of the impeller 8 is connected...

Embodiment 2

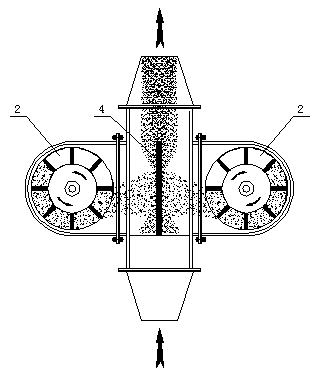

[0027] Embodiment two: see image 3 , this embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that: the throwing mechanism 2 is a symmetrical group or two groups, and the materials thrown out by the throwing mechanism 2 on both sides are simultaneously with the resistant The impact of the two board surfaces of the grinding impact plate 4 improves the efficiency and improves the stability of the wear-resistant impact plate 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com