Connection method of two connecting pipes

A connection method and a technology for connecting pipes, which are applied to welding equipment, tubular objects, aluminothermic welding equipment, etc., can solve the problems of difficult welding operation, long welding time, and limited position space, etc., and achieve good welding effect and high welding efficiency. The effect of short time and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

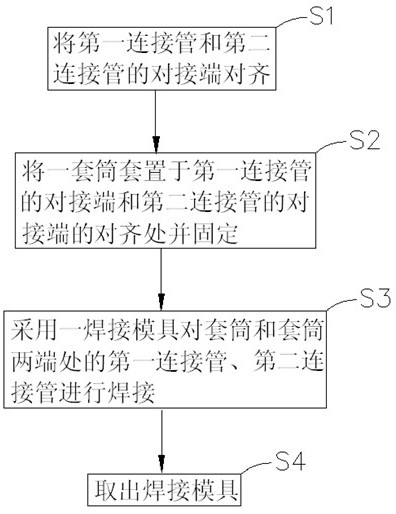

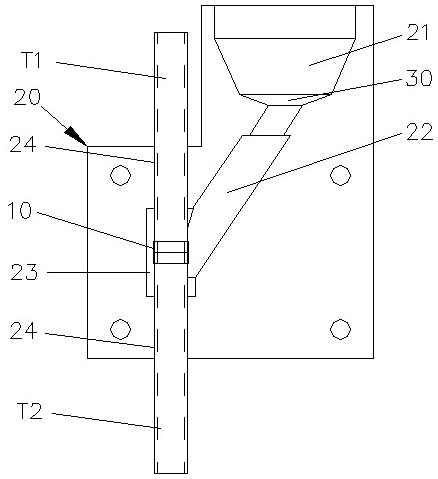

[0020] see figure 1 , figure 2 and image 3 , the method for connecting two connecting pipes of the present invention is used to connect the first connecting pipe and the second connecting pipe, comprising the following steps:

[0021] First S1, align the butt end of the first connecting tube T1 with the butt end of the second connecting tube T2;

[0022] Then S2, put a sleeve 10 in the alignment of the butt end of the first connecting pipe T1 and the butt end of the second connecting pipe T2 and fix it;

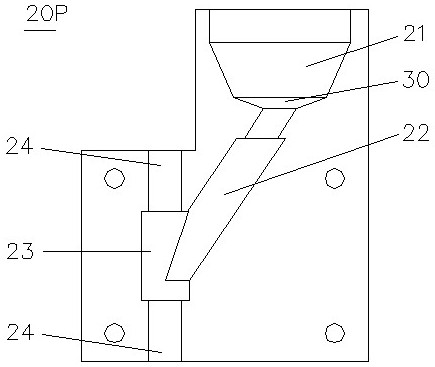

[0023] Next S3, using a welding mold 20 to weld the sleeve 10 and the first connecting pipe T1 and the second connecting pipe T2 at both ends of the sleeve.

[0024] The welding mold 20 is provided with a hopper 21, a flow channel 22, a cavity 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com