Press-fitting device and press-fitting method for scaling wheel shaft

A press-fitting device and axle technology, which is used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that the reduced-scale axle model cannot guarantee the quality of press-fitting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

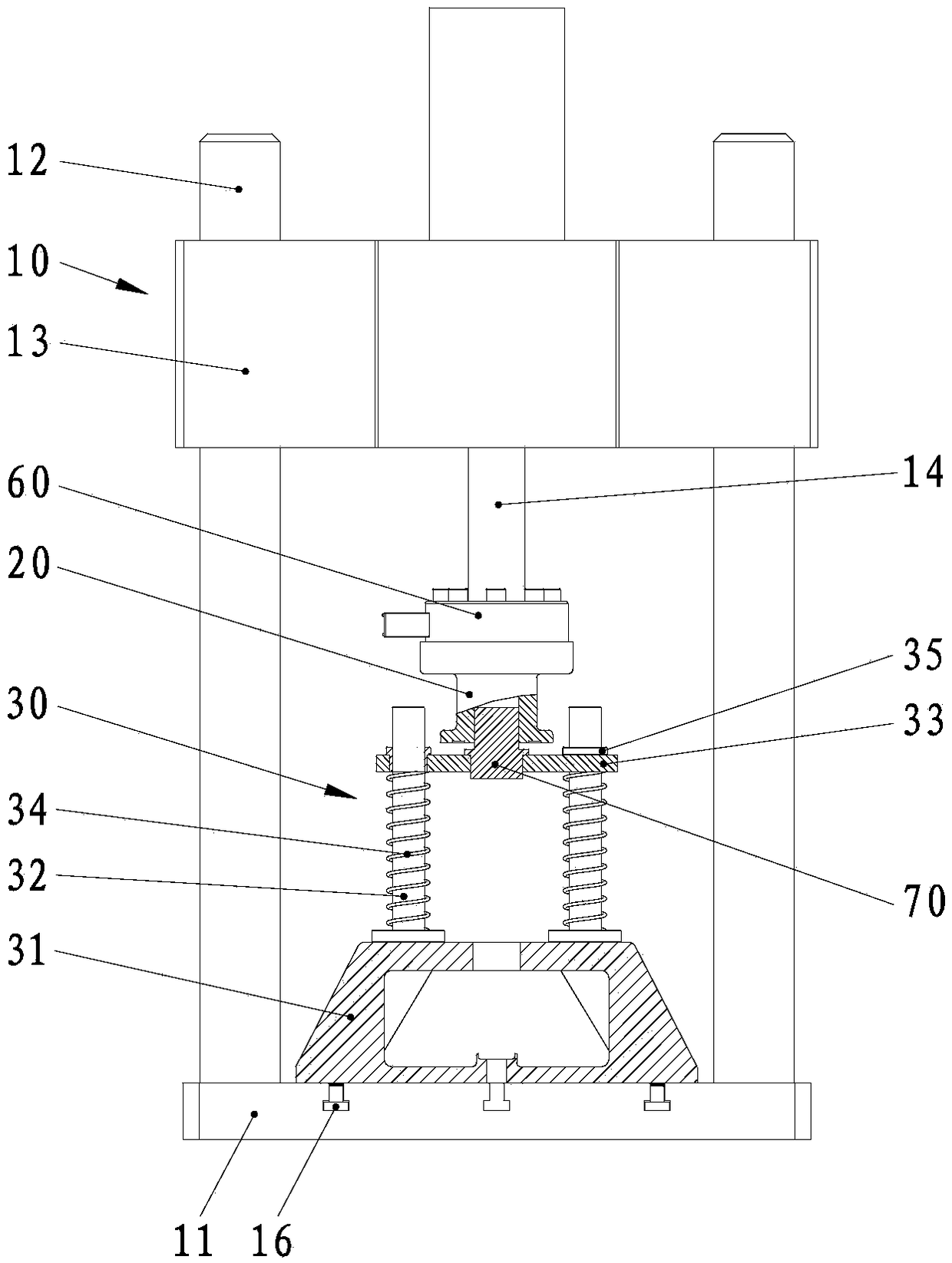

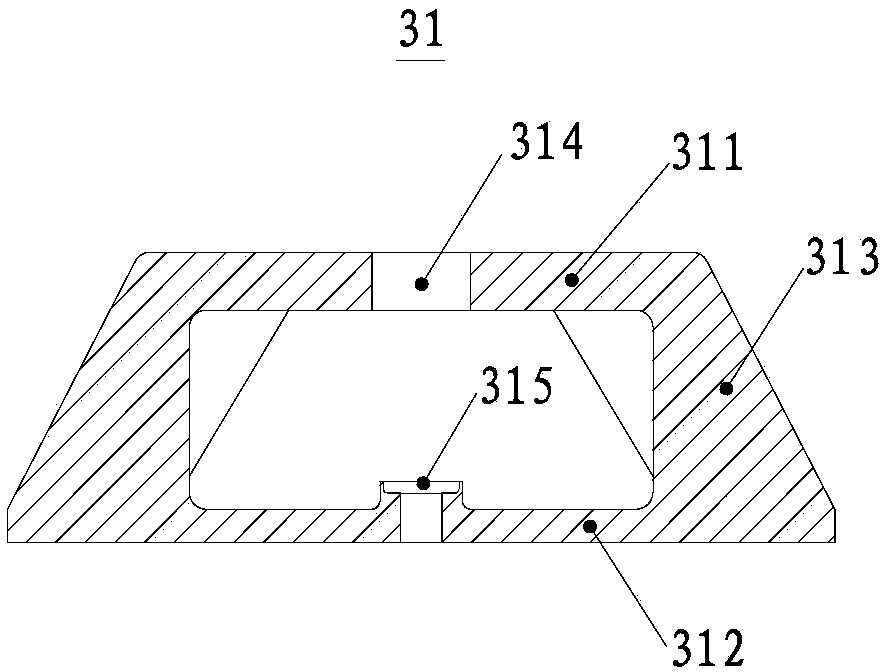

[0053] Please refer to figure 1 , the scaled wheel shaft pressing device, including the press 10, the wheel shaft pressing head 20, the fixing device 30 and the positioning pin 70. Both the axle pressing head 20 and the fixing device 30 are installed on the press 10 , the wheel axle pressing head 20 is arranged opposite to the fixing device 30 , and the positioning pin 70 is installed on the fixing device 30 .

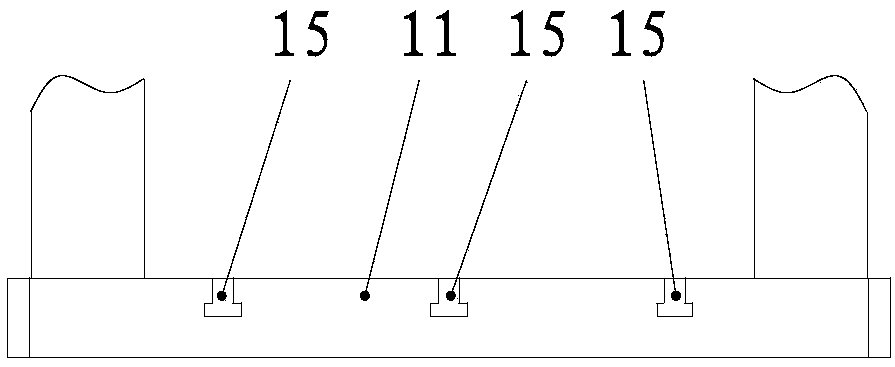

[0054] The press 10 comprises a base 11, a press guide column 12, a fuselage 13 and an actuator 14, the press guide column 12 is vertically installed on the base 11, the fuselage 13 is sleeved on the press guide column 12 and The fuselage 13 is slidably connected with the press guide column 12, and the actuator cylinder 14 is vertically installed in the middle of the fuselage 13 and faces the machine base 11. The actuator cylinder 14 can reciprocate in the vertical direction.

[0055] The top of the axle press-fitting head 20 is connected with the cylinder 14, and it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com