Method and device for disassembling segmented crankshaft of marine low-speed diesel engine

A diesel engine and crankshaft technology is applied in the field of disassembly and assembly of segmented crankshafts of marine low-speed diesel engines, which can solve problems such as difficulty in disassembling segmented crankshafts, and achieve the effects of ensuring torque transmission, reducing waste and returning rates, and avoiding strains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

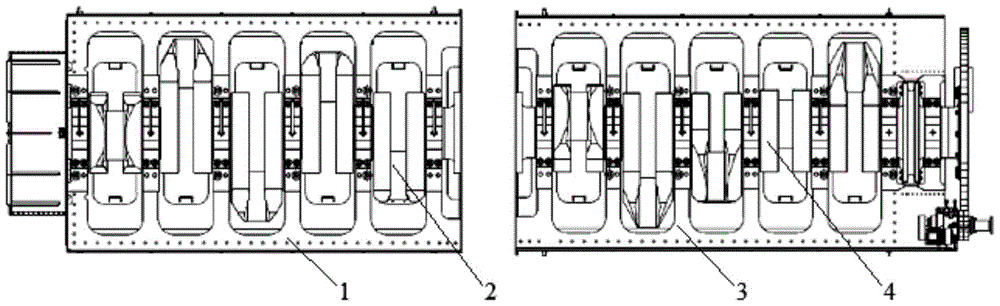

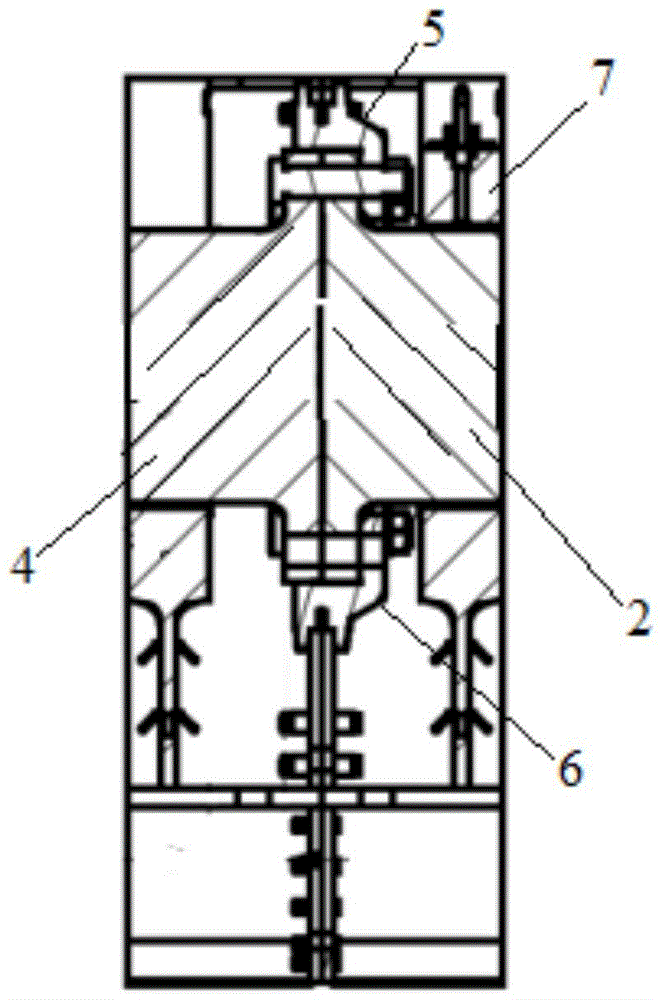

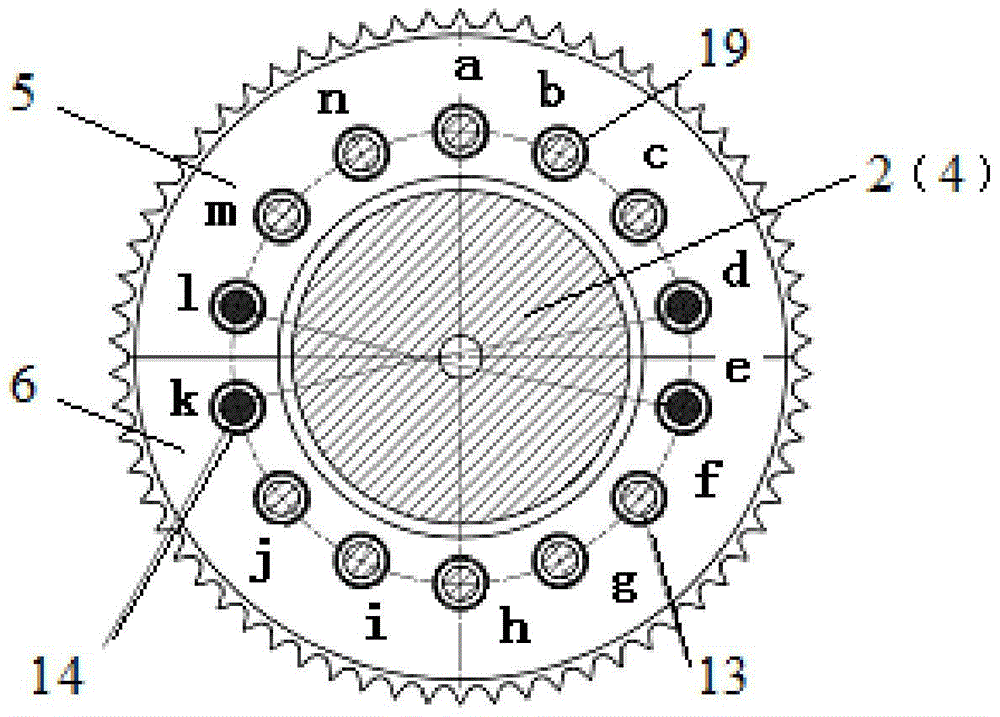

[0075] The 10S90MEC marine low-speed diesel engine includes a front frame 1, a rear frame 3, a front crankshaft 2, a rear crankshaft 4, an upper half sprocket 5, a lower half sprocket 6 and a main bearing cover 7, please refer to figure 1 , figure 2 and image 3 , wherein, the main bearing cap 7 installs the front crankshaft 2 on the front frame 1 at the journal to form the front frame crankshaft assembly, and installs the rear crankshaft 4 on the rear frame 3 to form the rear frame crankshaft assembly. become. The present invention is exactly the process flow method that proposes for solving the connection and disassembly of the front section crankshaft 2 and the rear section crankshaft 4. The upper half sprocket 5 and the lower half sprocket 6 are radially mounted on the junction of the front crankshaft 2 and the rear crankshaft 4 (see figure 2 ), the front section crankshaft 2, the rear section crankshaft 4, the upper half sprocket 5 and the lower half sprocket 6 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com