Servo conveying mechanism for baby's pull-up pants folded in half

A technology for baby pull-up pants and a conveying mechanism, which is applied in the directions of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of inclination of the crotch of pull-up pants, affecting the flatness of finished products, unfavorable compaction, etc. Stability, not easy to fall off, increase the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

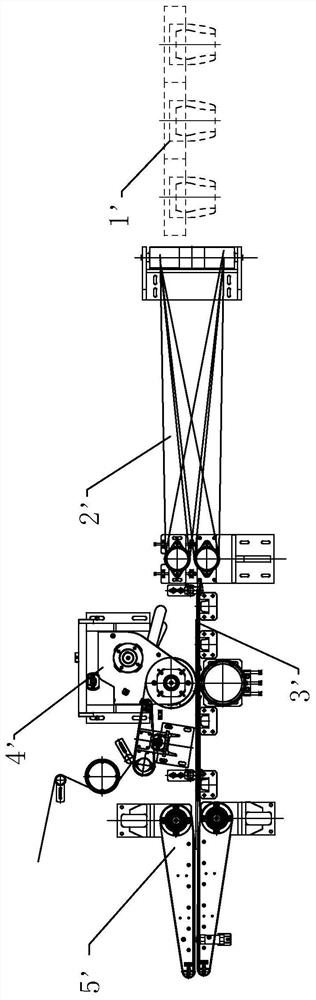

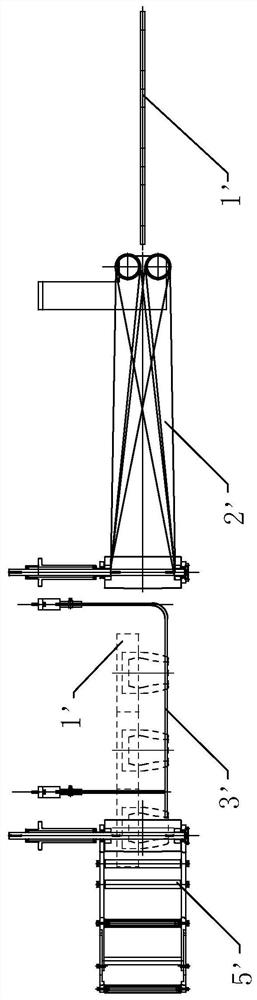

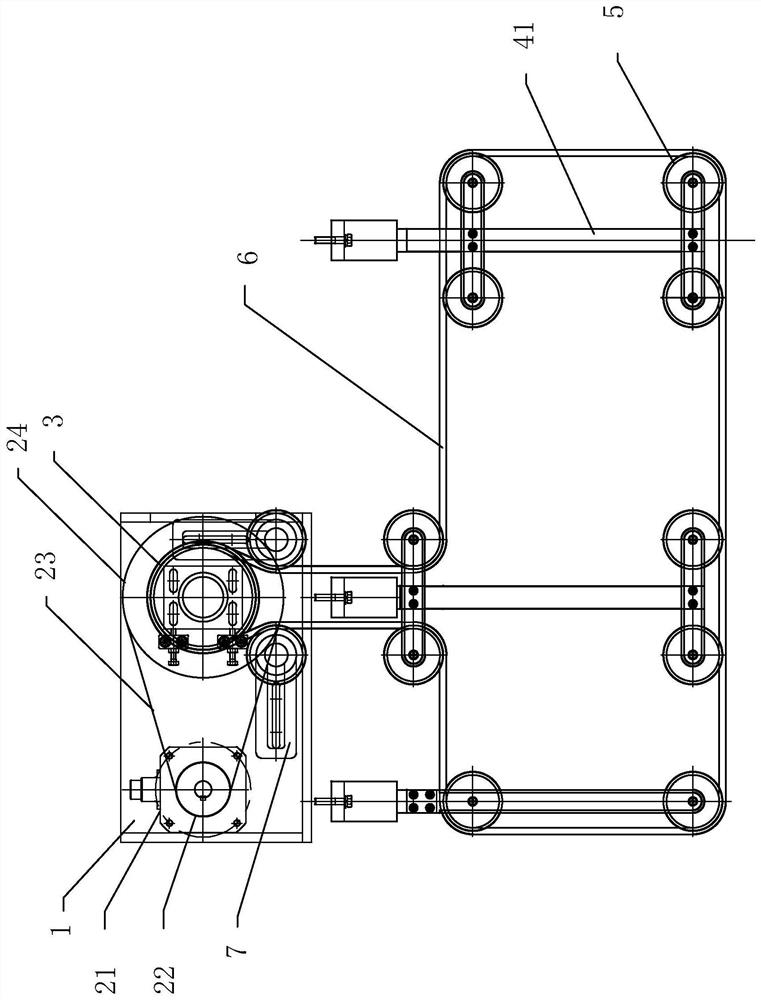

[0034] refer to Figure 3 to Figure 9 , this embodiment provides a servo conveying mechanism after the baby's pull-up pants are folded in half, including a frame 1, and the frame 1 is provided with a transmission assembly 2, an active guide wheel 3, a support frame and a plurality of passive guide wheels 5, A round belt 6 in a closed-loop state is stretched on the active guide pulley 3 and each passive guide pulley 5. The diameter of the round belt 6 is consistent with the thickness of the passive guide pulley 5. The frame 1 is provided with a round belt tensioner. Institution 7.

[0035] The transmission assembly 2 includes a servo motor 21 , a first synchronous pulley 22 arranged at the output end of the servo motor 21 , and a second synchronous pulley 24 driven by a belt 23 with the first synchronous pulley 22 . The rotating shaft 25 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com