Spring fixing structure of rolling rotor compressor and rolling rotor compressor

A rolling rotor type, spring-fixed technology, applied in the field of compressors, can solve problems such as spring failure and deformation, and achieve the effect of ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

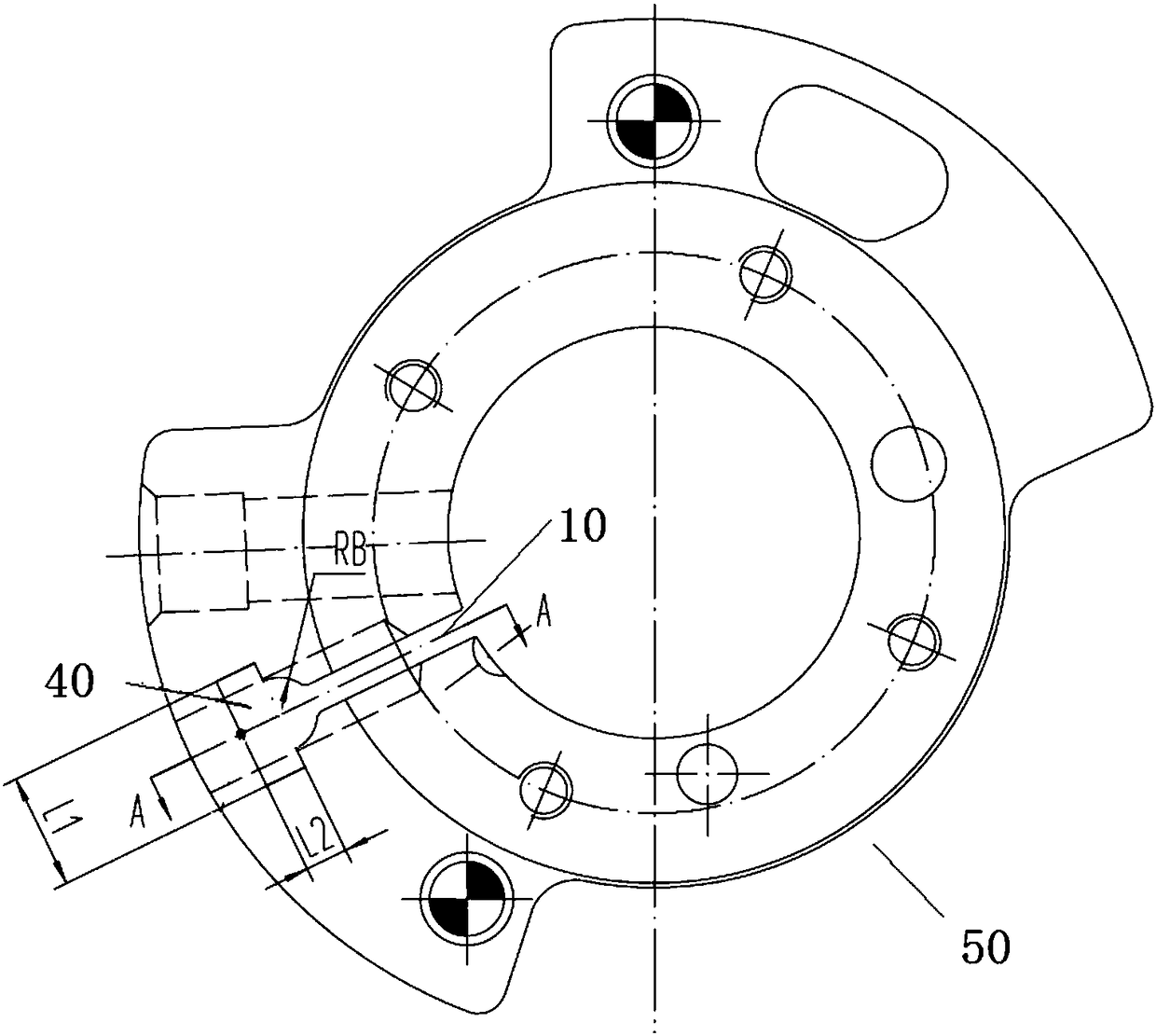

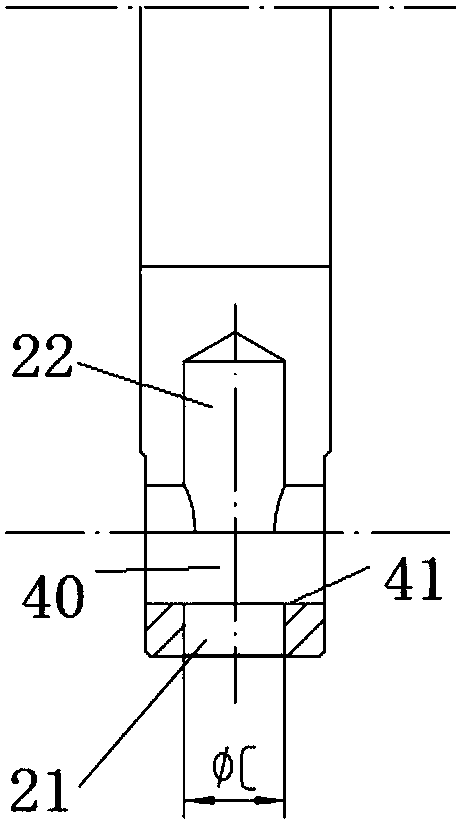

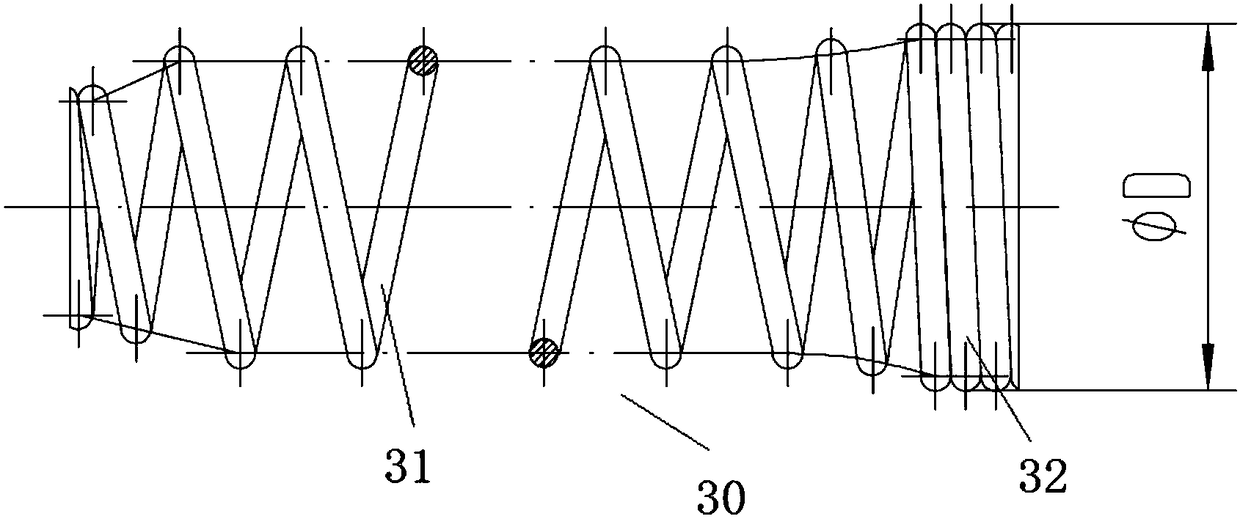

[0042] This embodiment provides a spring fixing structure for a rolling rotor compressor, such as figure 1 , figure 2 As shown, it includes: a spring hole 20 formed on the body of the cylinder 50, extending radially from the outer wall surface of the cylinder 50 to the slide groove 10 where the slide is installed; a fixed cavity 40 formed on the body of the cylinder 50, which is The spring hole 20 is close to the outer wall surface of the cylinder 50 and is composed of an enlarged part along the aperture; the spring 30 has a biasing part 31 which is arranged in the spring hole 20 and can be freely expanded and contracted, and a connected radially enlarged fixing part 32 , the biasing end of the biasing part 31 is against the sliding plate, the diameter of the fixing part 32 is larger than the diameter of the spring hole 20 and is supported in the fixing cavity 40; the fixing cavity 40 resists the The contact part 41 of the spring 30 is a plane, so that the fixed part 32 of t...

Embodiment 2

[0052] A rolling rotor compressor provided in this embodiment includes: a cylinder 50, rollers are arranged in the cylinder 50, a sliding vane groove 10 is opened on the cylinder 50, and a sliding vane groove 10 is arranged in the sliding vane groove 10. A spring hole 20 communicating with the slide groove 10 is formed on the outer wall of the cylinder 50. One end of the spring 30 is against the slide, and the other end is fixed in the spring hole by the spring fixing structure in Embodiment 1. 20, thereby having all the advantages described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com