Manual rapid construction railway transport armored vehicle unloading temporary platform

A temporary platform and fast technology, applied in the loading and unloading of railway vehicles, railway car body parts, stations, etc., can solve the problems of being unsuitable for emergency use, etc., achieve short construction and assembly time, light overall weight, and prevent rollover accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments and drawings described here are only used to explain the general structure and working principle of the present invention, and do not represent a limitation to the present invention.

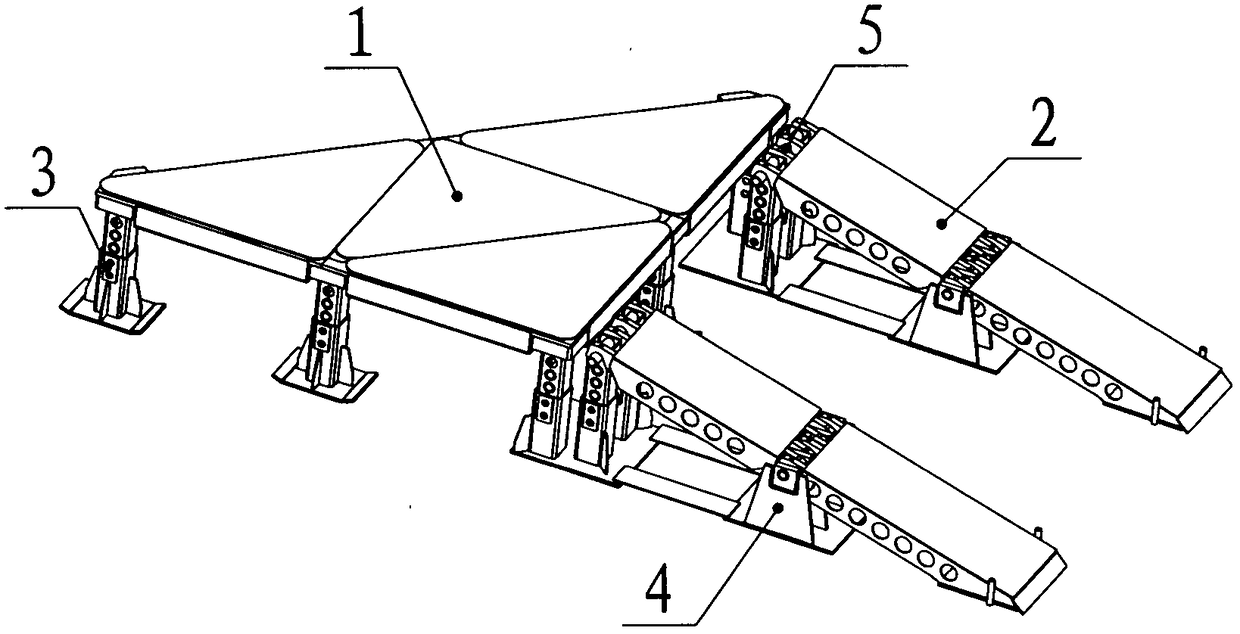

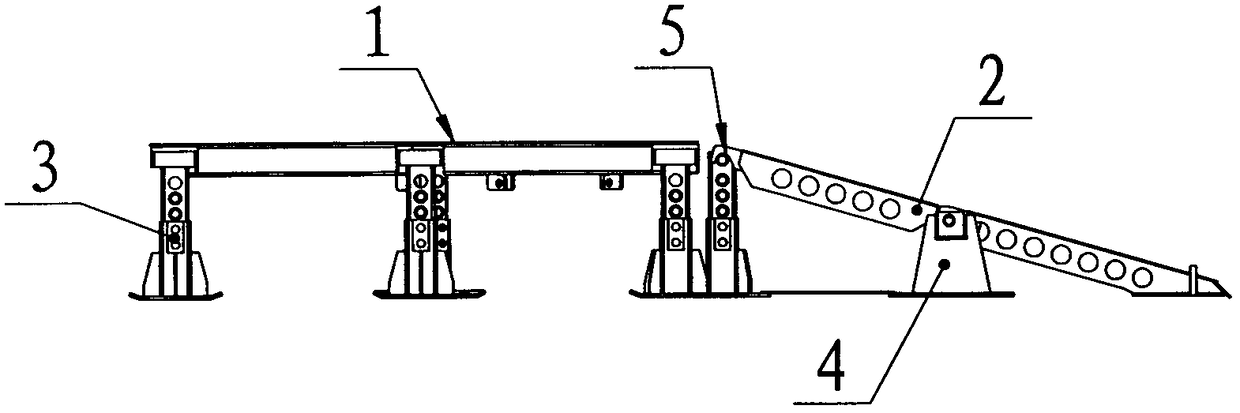

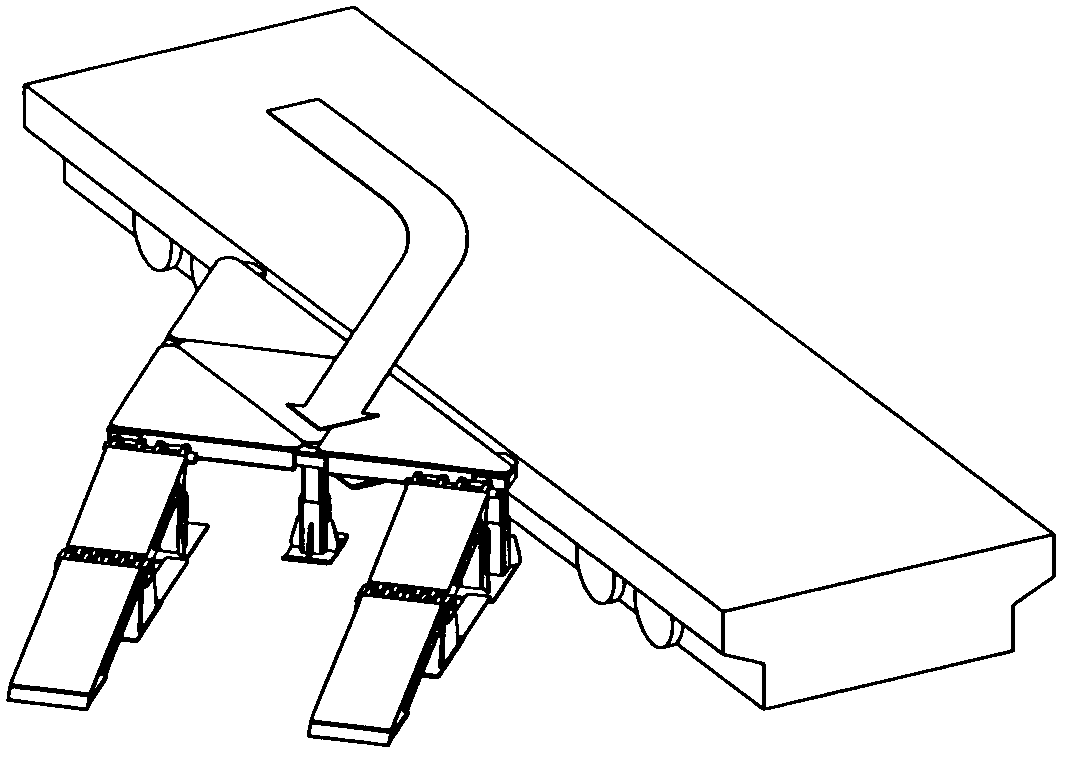

[0017] Examples of the present invention figure 1 and figure 2 Shown: the temporary platform for the unloading of armored vehicles by artificial rapid construction, including a guiding platform and at least two or more inclined tracks, is characterized in that a 45° right-angled triangular platform plate 1 is set between the flat car and the inclined track 2 . A plurality of height-adjustable vertical support feet 3 are arranged under the platform board 1 . The slope track 2 is composed of more than two track monomers with an inclination angle of 16° to 25° to the ground, and the hook type hinge 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com