Prefabricated curtain board and protecting wall formwork construction trolley for viaduct surface of high-speed train

A technology for elevated bridge decks and construction trolleys, which is applied in the direction of erecting/assembling bridges, bridges, and load-carrying blocks. It can solve problems such as high cost, high safety risk, and large space occupation, and achieve wear-resistant and damaged repairs and improve overall efficiency. , very little damage repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

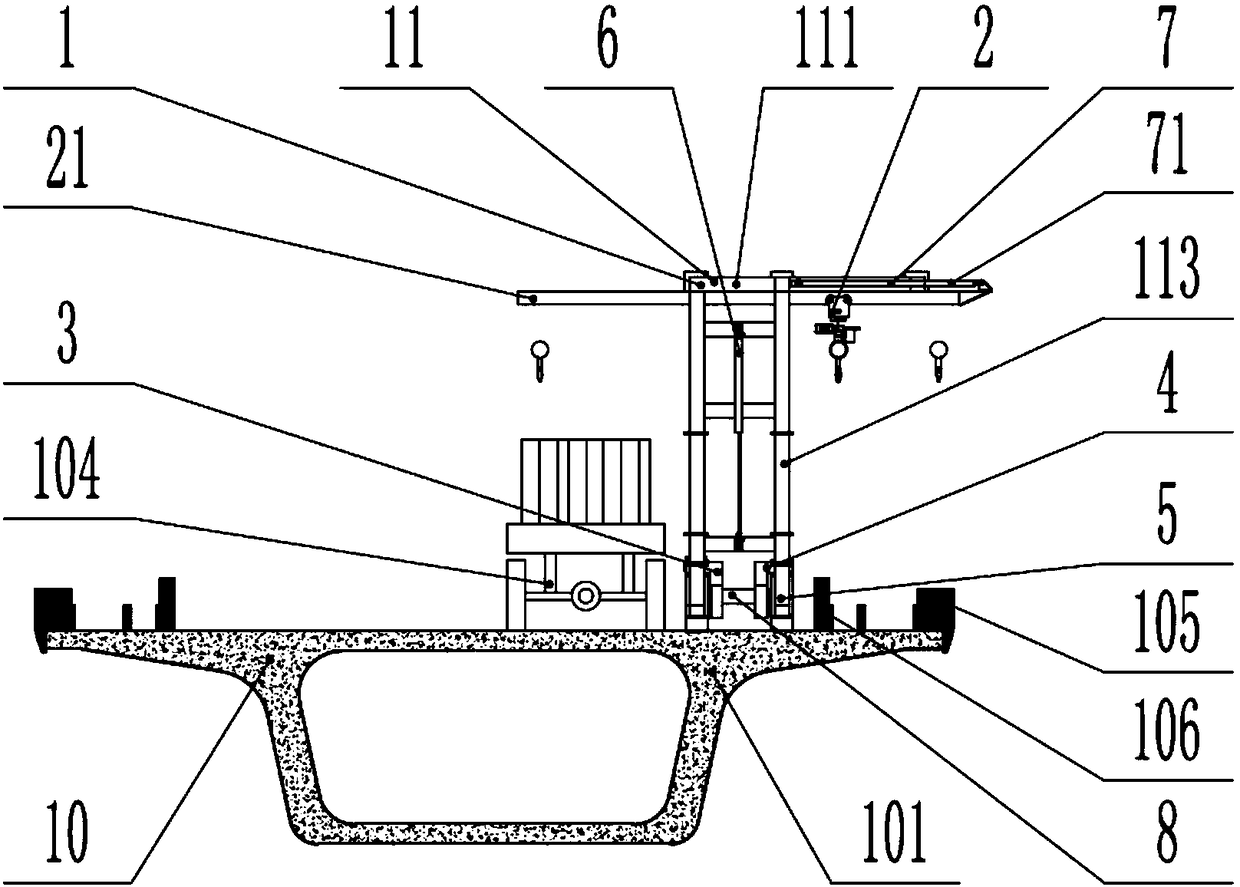

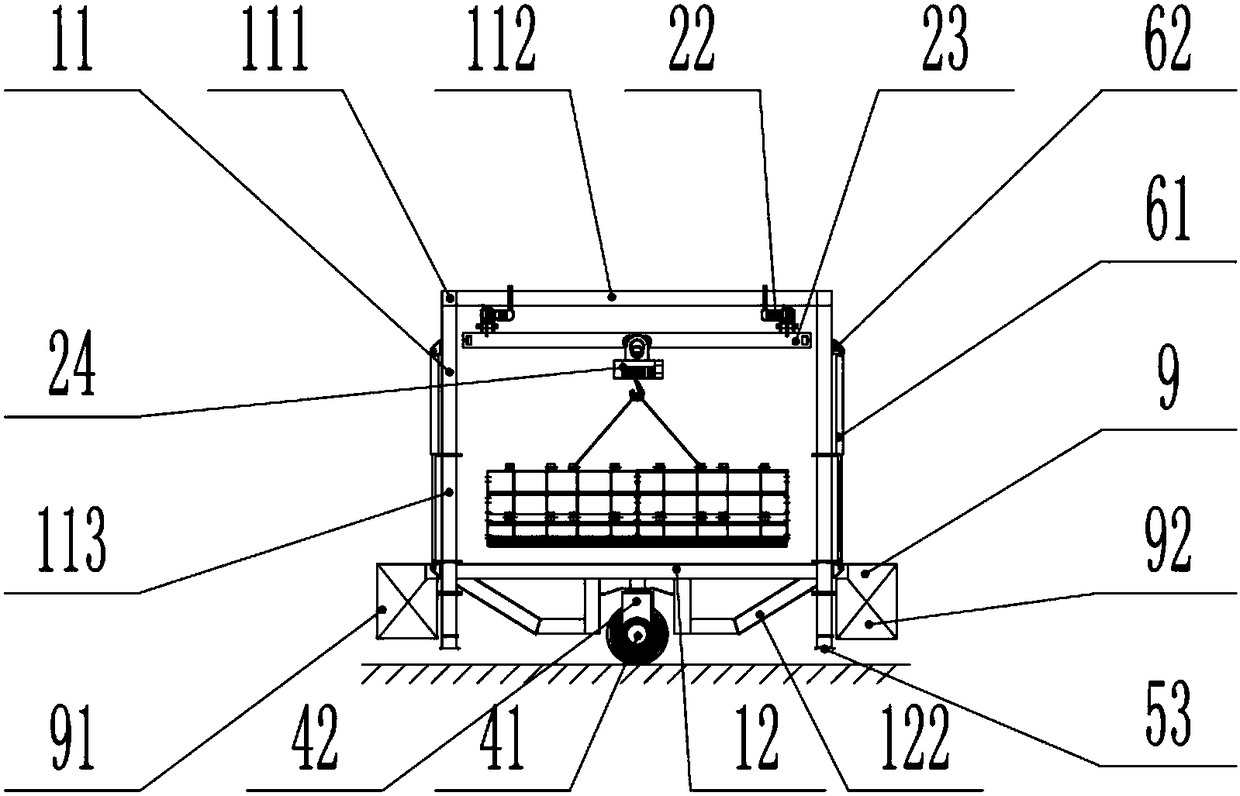

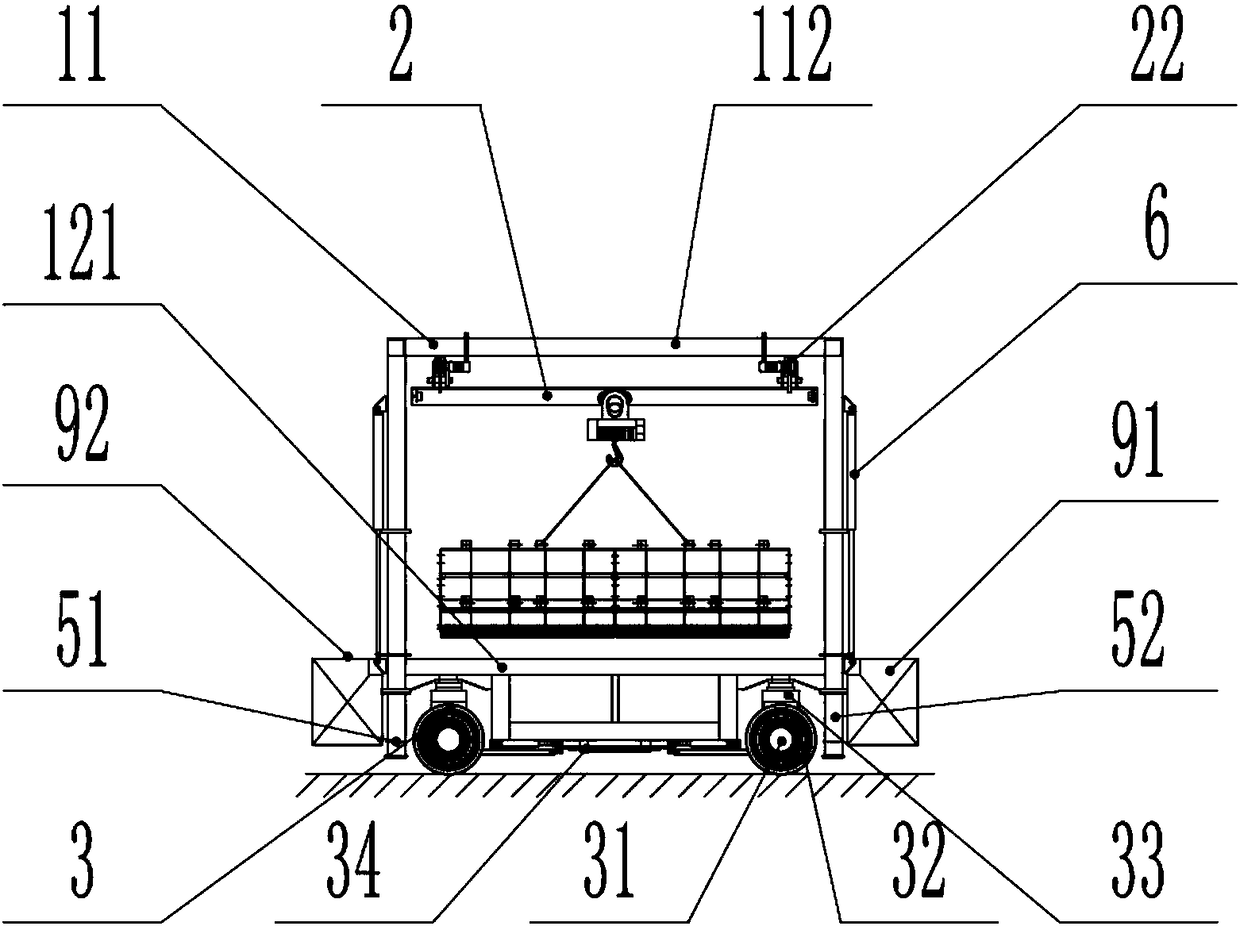

[0043] Such as Figure 1 to Figure 7 Shown is the high-speed railway viaduct prefabricated deck and protective wall formwork construction trolley of the present invention, including frame structure assembly 1, suspension crane assembly 2, double steering wheel assembly 3, fixed single wheel assembly 4, outrigger mechanism Assembly 5, frame lifting assembly 6, track beam telescopic assembly 7, bottom counterweight assembly 8, power electronic control assembly 9, etc. Among them, the frame structure assembly 1 is the mounting and carrying part of all mechanism devices, including the upper frame structure 11 and the lower frame structure 12 . The suspension crane assembly 2 includes a crane running track beam 21 , a crane running mechanism 22 , a crane carrying main beam 23 and a lifting electric hoist 24 . The double steering wheel assembly 3 comprises a double wheel driving mechanism 31, a steel ring solid wheel assembly 32, a double wheel side wheel support structure 33 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com