Hoisting-free self-loading and unloading hydraulic box

A self-loading and unloading, hydraulic technology, used in packaging, lifting devices, transportation and packaging, etc., can solve the problems of cumbersome operation steps, inability to avoid lifting and disassembly, inconvenient wireless control, etc., to ensure convenience, improve shock absorption effect, Guaranteed quickness and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

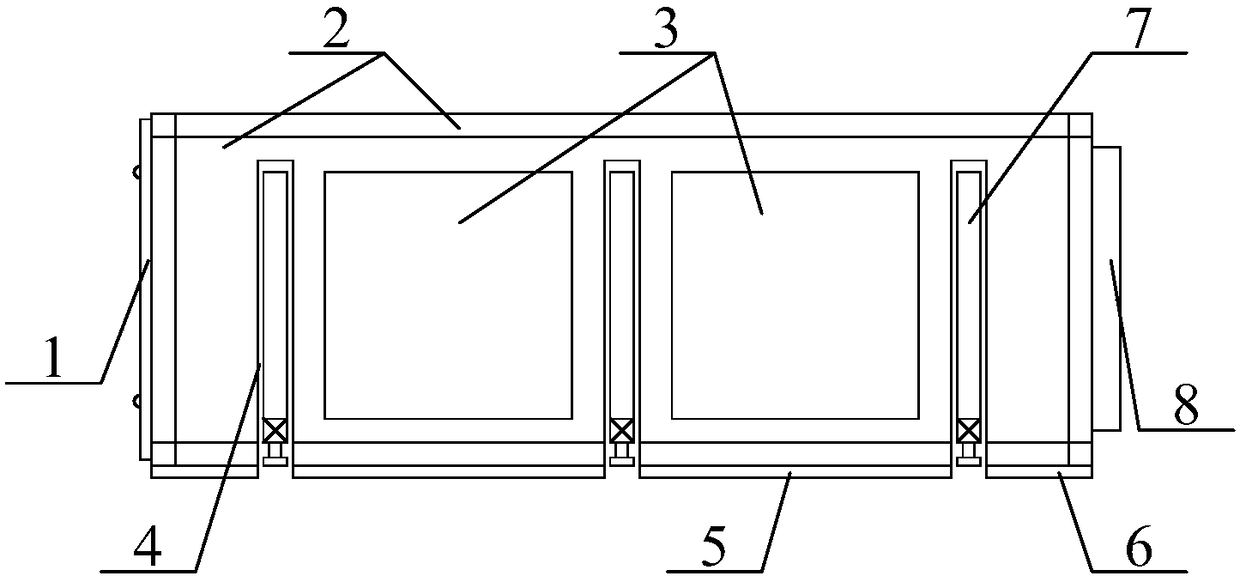

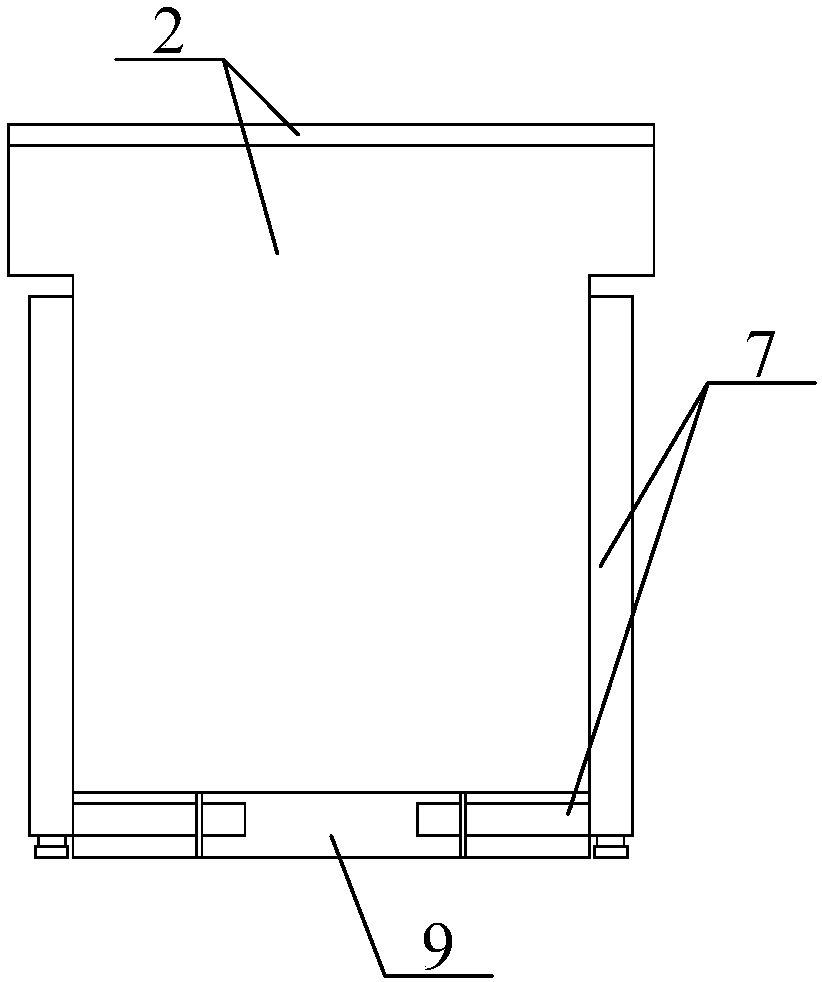

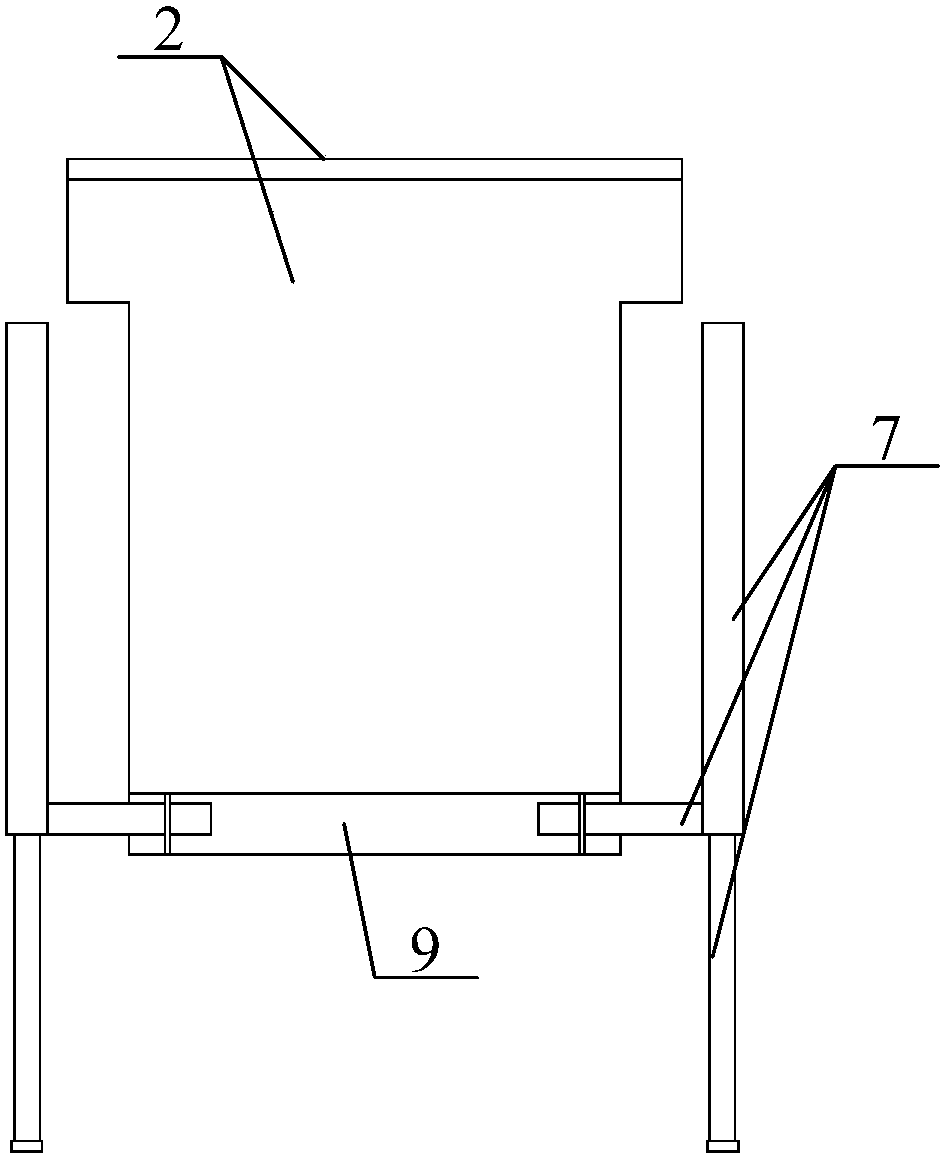

[0034] as attached figure 1 to attach Figure 5 shown

[0035] The invention provides a lifting-free self-loading and unloading hydraulic box body, which includes a container door 1, a container body 2, a container side door 3, an installation groove 4, a protective pad 5, an anti-skid pad 6, an L-shaped hydraulic jacking rod structure 7, and a hydraulic pump station 8 and bottom groove 9, the hinge of the container door 1 is installed at the entrance of the left end of the container body 2; The middle position of the upper part; the installation grooves 4 are set longitudinally on the left side of the front surface of the container body 2, the middle position and the middle position on the right side; side position, middle position and middle position on the right side; the protective pad 5 is respectively mounted on the left and right sides of the bottom of the container body 2 by horizontal bolts; positions at both ends; the L-shaped hydraulic jacking rod structure 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com