Electricity distribution network tree branch obstacle automatic cleaning device

An automatic cleaning and distribution network technology, applied in the direction of electric pruning saws, signal transmission systems, instruments, etc., can solve the problems of complex structure, high cost, and inability to completely solve the problem of tree branch damage, so as to ensure flexibility and ease of use. operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

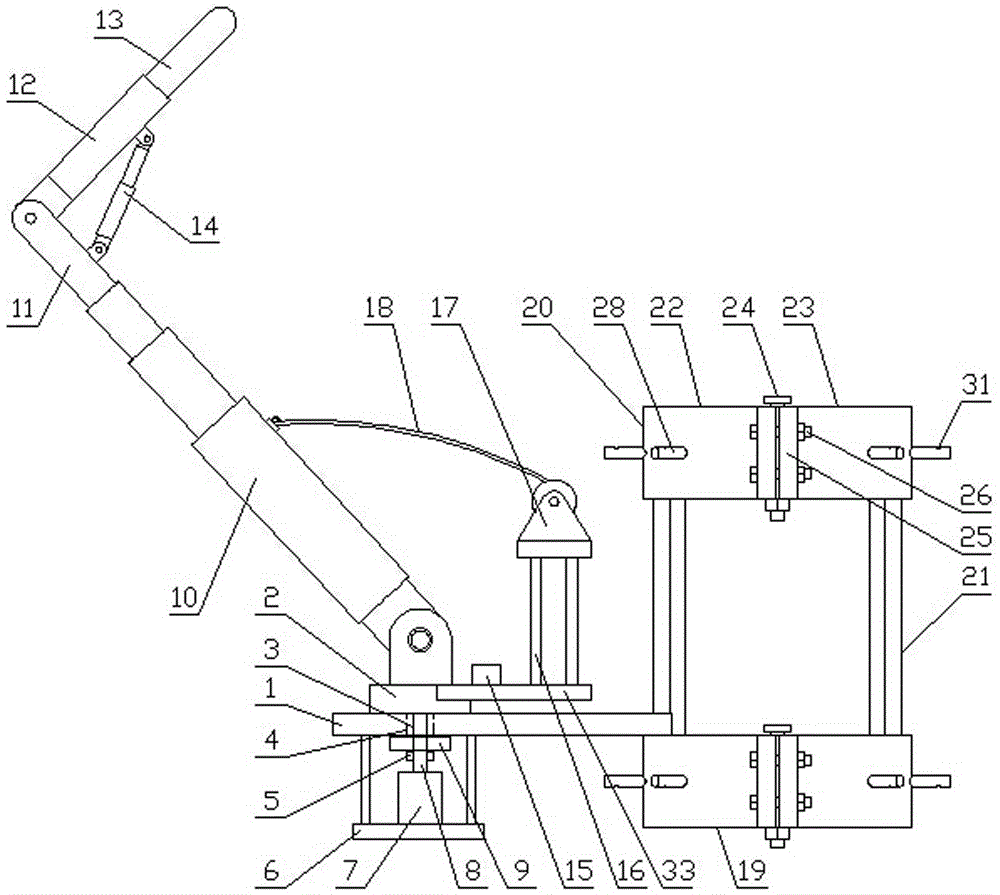

[0030] Embodiment one: if figure 1 , figure 2 and image 3 As shown, an automatic cleaning device for branch obstacles in a distribution network includes a platform 1, a hinge seat 2 is installed on the upper left side of the platform 1, a hinge seat 2 is provided on the bottom of the hinge seat 2, and a rotating shaft 3 is provided on the platform 1. The shaft hole 4 matched with the rotating shaft 3, the pinion 5 is arranged at the bottom of the rotating shaft 3, the hanging platform 6 is suspended at the left bottom of the platform 1 corresponding to the position of the rotating shaft 3, and the driving motor is arranged on the hanging platform 6 7. The output shaft 8 of the drive motor 7 is provided with a large gear 9 matched with the pinion 5 .

[0031] The first electric telescopic rod 10 is rotated on the hinge base 2, and the first support arm 11 is fixedly arranged on the upper end of the first electric telescopic rod 10, and the second support arm 12 is arranged ...

Embodiment 2

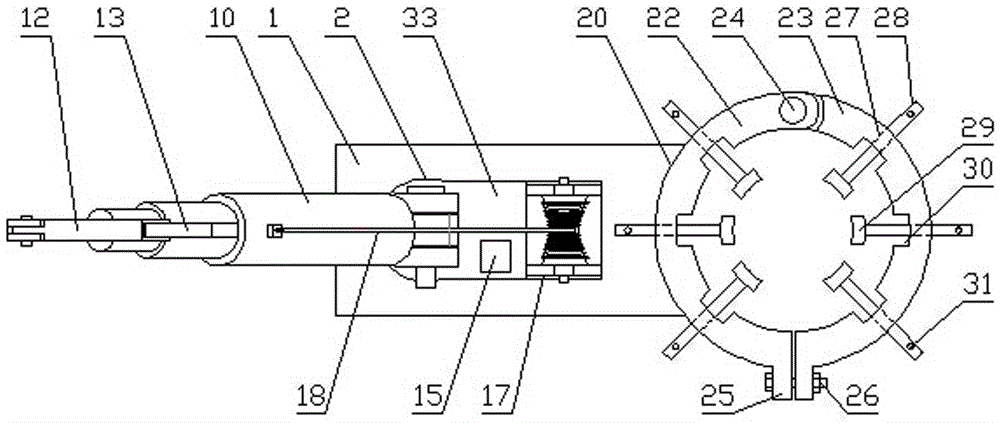

[0041] Embodiment two: if Figure 4 and Figure 5 As shown, an automatic cleaning device for branch obstacles in a distribution network includes a platform 1, a hinge seat 2 is installed on the upper left side of the platform 1, a hinge seat 2 is provided on the bottom of the hinge seat 2, and a rotating shaft 3 is provided on the platform 1. The shaft hole 4 matched with the rotating shaft 3, the pinion 5 is arranged at the bottom of the rotating shaft 3, the hanging platform 6 is suspended at the left bottom of the platform 1 corresponding to the position of the rotating shaft 3, and the driving motor is arranged on the hanging platform 6 7. The output shaft 8 of the drive motor 7 is provided with a large gear 9 matched with the pinion 5 .

[0042] The first electric telescopic rod 10 is rotated on the hinge base 2, and the first support arm 11 is fixedly arranged on the upper end of the first electric telescopic rod 10, and the second support arm 12 is arranged on the uppe...

Embodiment 3

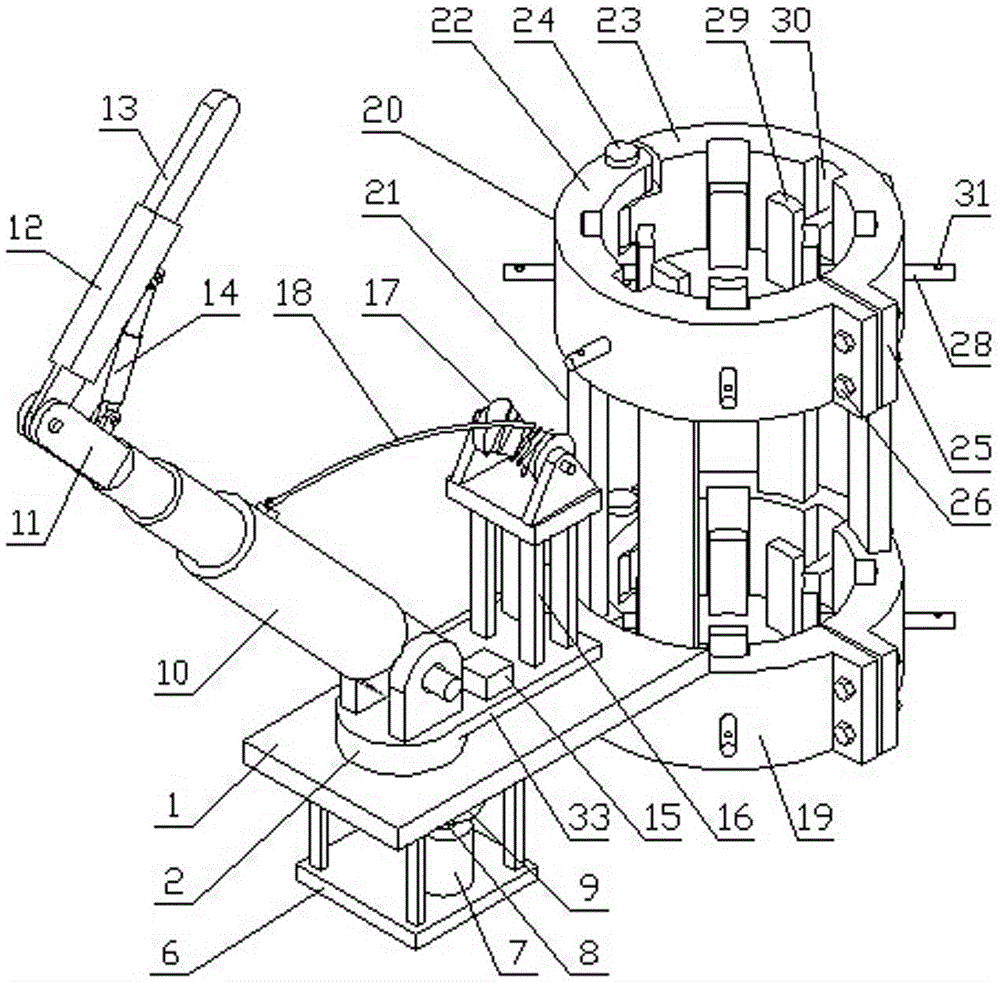

[0051] Embodiment three: as Figure 6 As shown, the difference between it and the second embodiment is that: the inner surface of the arc-shaped pressing plate 29 is provided with an elastic layer 33 .

[0052] The elastic layer 33 is made of wear-resistant rubber, and the wear-resistant rubber is prepared from the following raw materials in parts by weight: 48 parts of nitrile rubber, 10 parts of butadiene rubber, 14 parts of titanium dioxide, 7 parts of carbon fiber, carbon 4 parts of black, 1 part of nano-zinc oxide, 8 parts of stearic acid, 3 parts of anti-aging agent, 5 parts of microcrystalline wax. The wear-resistant rubber uses nitrile rubber and butadiene rubber with good wear resistance as the main material, and adds wear-resistant components such as titanium dioxide and carbon fiber with high strength and strong wear resistance. The wear-resistant rubber pad is low in cost and aging resistant Excellent performance and chemical corrosion resistance, good elasticity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com