Straight-pipe pressure balanced expansion joint with three-direction compensations

An expansion joint, balanced technology, which is applied to expansion compensation devices, pipe components, pipes/pipe joints/fittings for pipelines, etc., can solve the problems of excessive outer diameter, high manufacturing cost, heavy weight, etc. Weight, simple structure, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

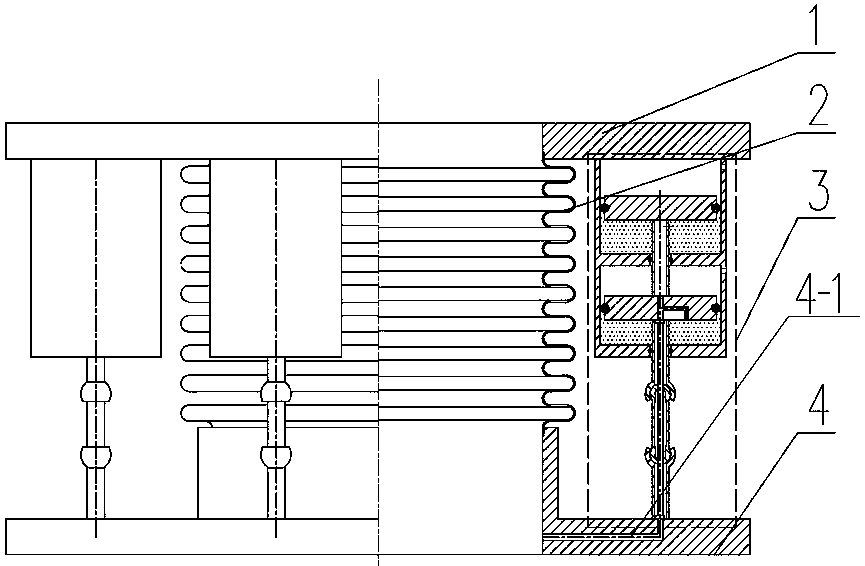

[0018] The preferred embodiments of the invention are given below in conjunction with the accompanying drawings to describe the technical solutions of the present invention in detail. Here, the present invention will be described in detail with reference to the accompanying drawings. It should be noted that the preferred implementation examples described here are only used to illustrate and explain the present invention, and are not used to limit or limit the present invention.

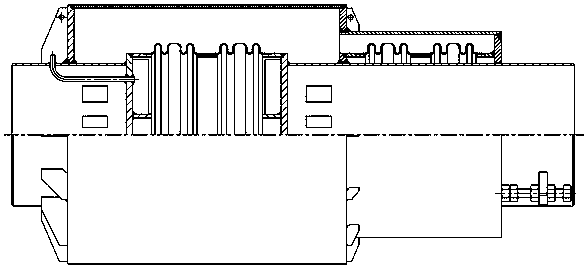

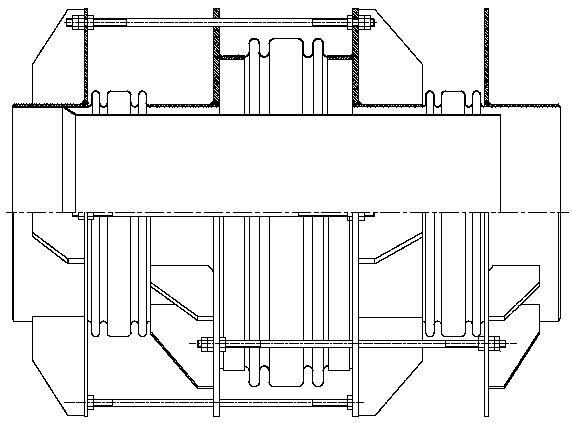

[0019] Such as image 3 As shown, a straight pipe pressure balance expansion joint with three-way compensation is composed of flange A1, working bellows 2 and flange B4 connected in sequence, and the working bellows between flange A1 and flange B4 2 There are a plurality of balance members 3 on the outer circumference, and the number pointed out in the patent is at least two. When flange A 1 is used as a medium inlet, flange B 4 is used as a medium outlet, or when flange A 1 is used as a medium When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com