Tooling through hole detection method

A technology for tooling and workpieces, which is applied in the field of measuring round holes and evaluating using laser trackers, and can solve the problems of not being able to reflect the use status, error amplification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

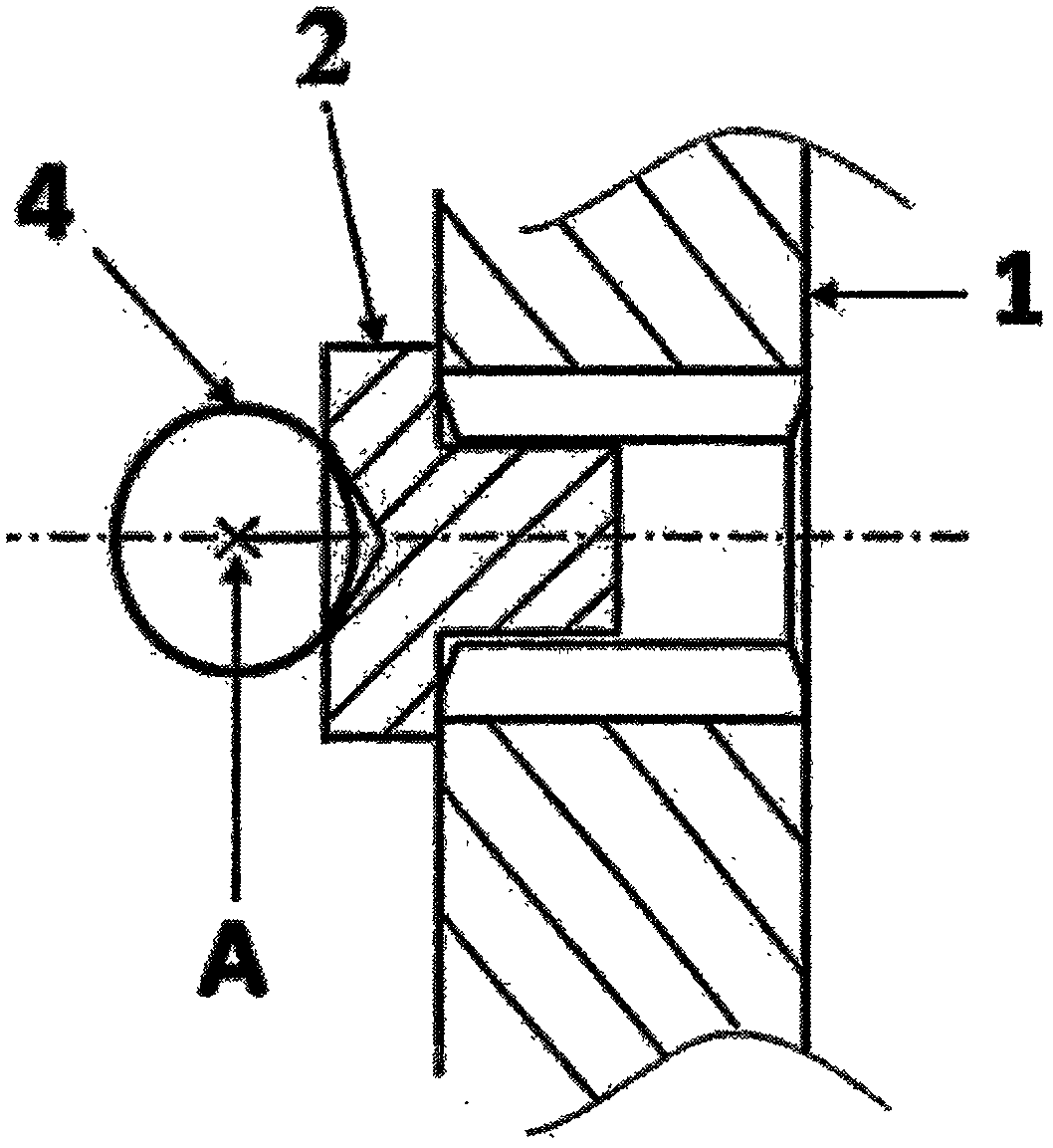

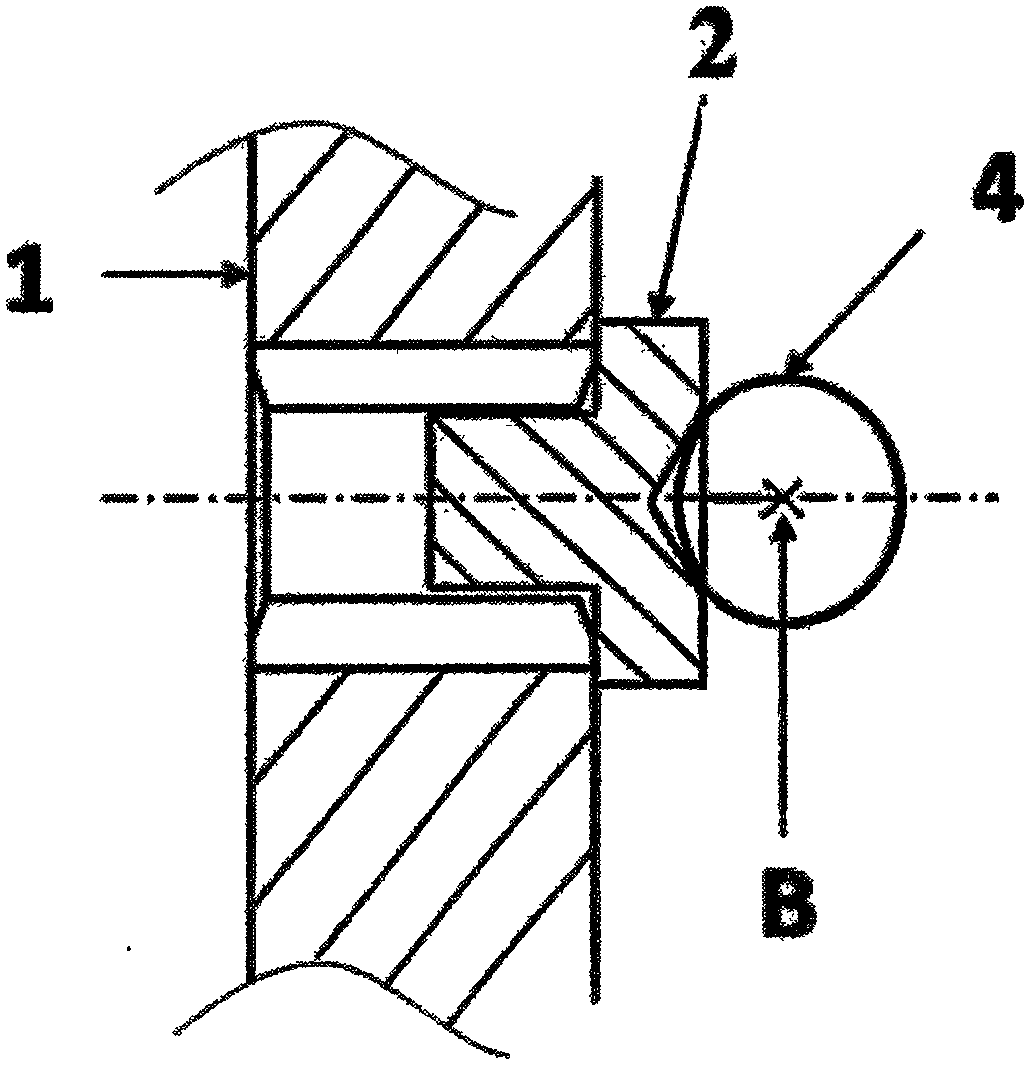

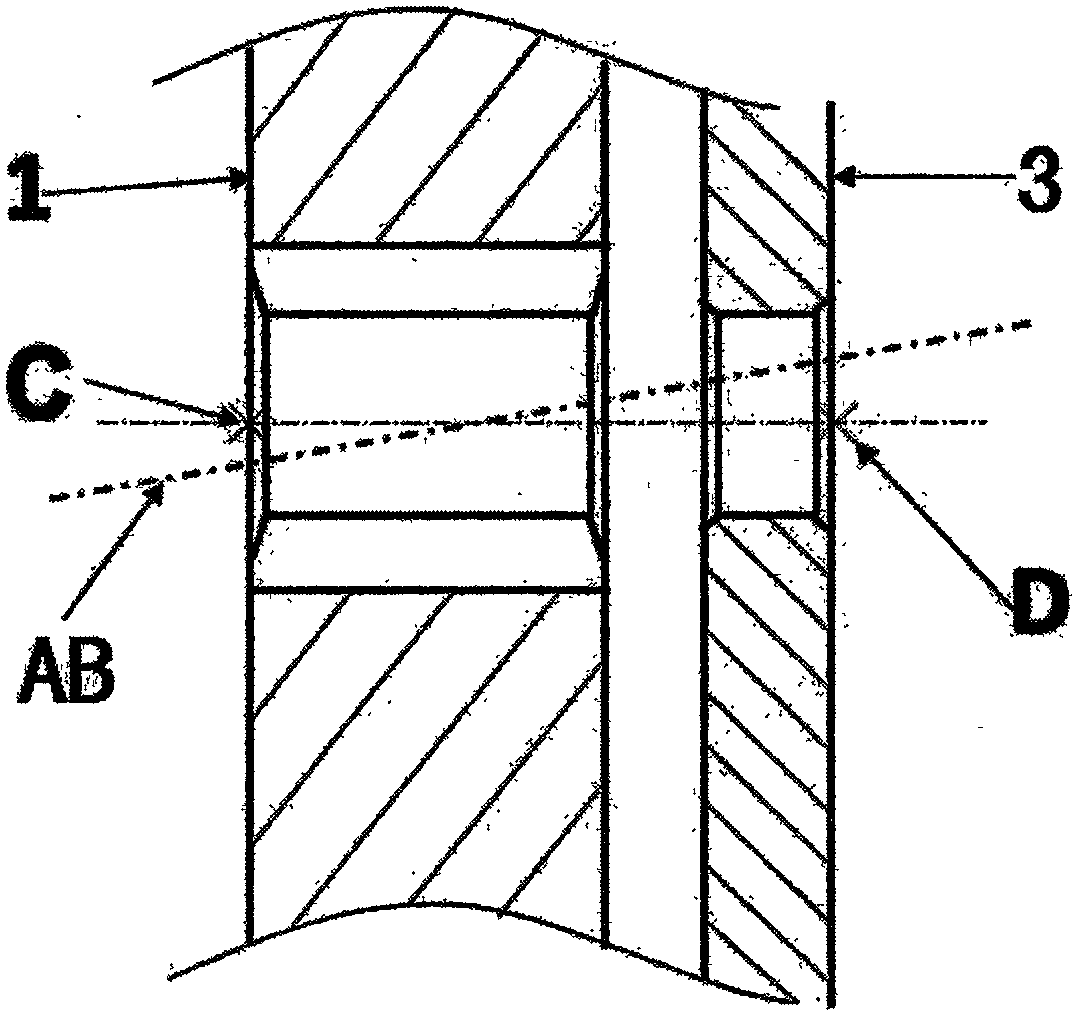

[0021] The laser tracker detection needs to use the target ball 4, the first target ball seat 2 and the second target ball seat 3, and the diameters of the first target ball seat 2 and the second target ball seat 3 should be consistent with the diameter of the circular hole. Regarding the target ball seat, the second target ball seat 3 is longer than the first target ball seat 2 If only one kind of target ball seat can be used for the measurement space

[0022] Two-point method for measuring circular holes:

[0023] Step 1 Place the first target ball seat 2 on the left surface of the circular hole of the workpiece 1, then place the target ball 4 on the first target ball seat 2, and measure point A with a laser tracker.

[0024] Step 2 Place the second target ball seat 3 together with the target ball 4 on the left surface of the round hole of the workpiece 1, and measure point B with a laser tracker. Or, the first target ball seat 2 and the target ball 4 are placed on the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com