Composition comprising gluten-free flour and hydroxypropyl methyl cellulose

A technology of hydroxypropyl methylcellulose, composition, applied in the field of management of gluten-related disorders in individuals, capable of solving problems such as inability to maintain shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0030] All parts and percentages are by weight unless otherwise indicated. In the examples, the following test procedure was used.

[0031] Crumb hardness

[0032] The hardness measured 1 day after baking is referred to as "initial hardness". Hardness measured after 1 day after baking is called hardness over storage time and is a measure to determine shelf life. During the period between i) baking and cooling and ii) hardness measurement, the loaves were stored in polyethylene bags. Low initial hardness and / or low hardness over storage time are desirable.

[0033] For texture analysis, a modified version of AACC method 74-09 (American Association of Cereal Chemists) was applied. Firmness of wheat bread and gluten-free bread was measured with a texture analyzer TA.XTplus (Stable Microsystems Ltd., Godalming, Surrey, UK) using the following settings:

[0034] - Sample preparation: 25 mm thick bread slices freshly cut from the center of the bread loaf;

[0035] -5kg load c...

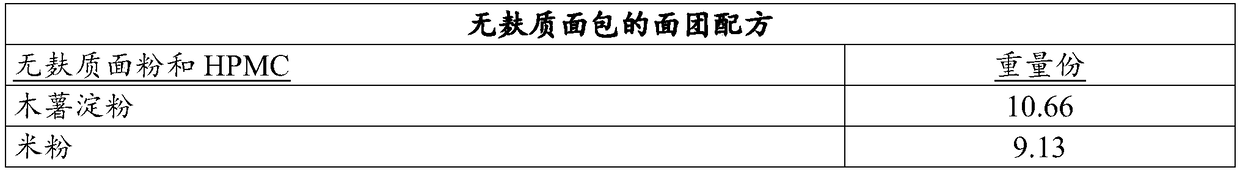

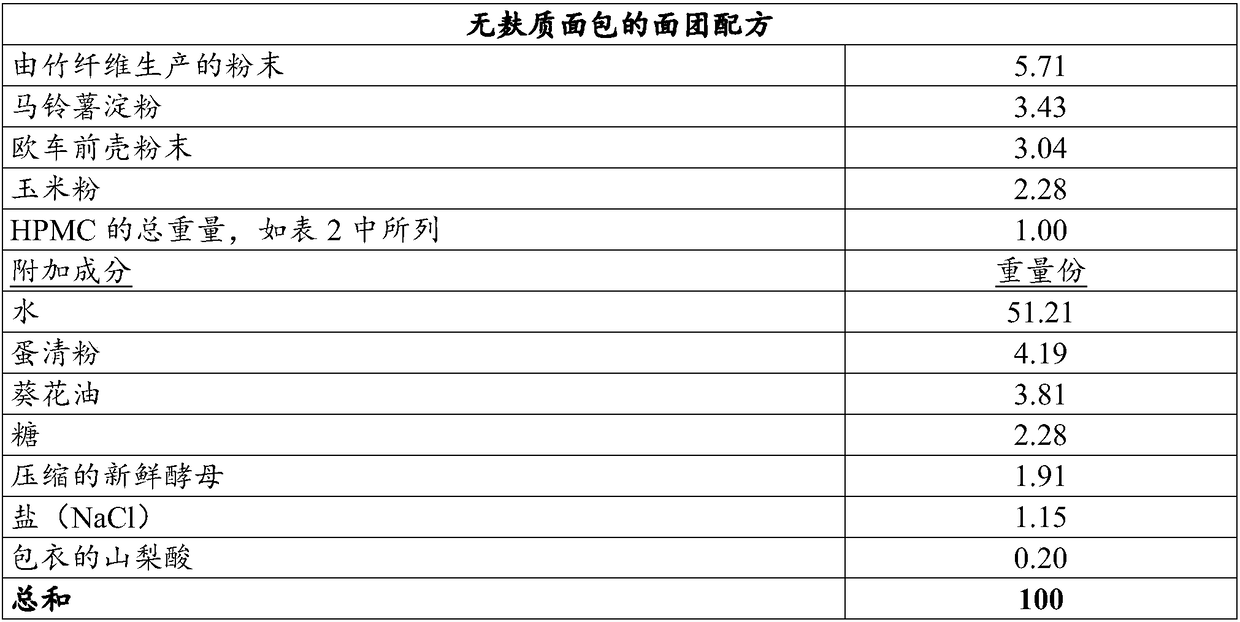

example 1-4 and comparative example A and B

[0040] Doughs were prepared from the ingredients listed in Tables 1 and 2 below. Hydroxypropylmethylcellulose (HPMC) b) has a methoxyl content of 19% to 24%, a hydroxypropoxyl content of 7% to 12%, and a viscosity of 3000 to 5000 mPa·s at 20°C Measured in 2% by weight aqueous solution. HPMC b) is available from The Dow Chemical Company as METHOCEL TM K4M cellulose ether is commercially available; abbreviated as "K4M" in Table 2 below. HPMC c) has a methoxyl content of 28% to 30%, a hydroxypropoxyl content of 7% to 12%, and a viscosity of about 19 mPa·s, measured at 20° C. in a 2% by weight aqueous solution. HPMC c) is available from The Dow Chemical Company as METHOCEL TME19 cellulose ethers are commercially available; abbreviated as "E19" in Table 2 below.

[0041] To prepare the dough, weigh all dry ingredients into a container and mix well. Add liquid ingredients to dry ingredients under high shear. The dough was kneaded for 6 minutes and then transferred to a grease...

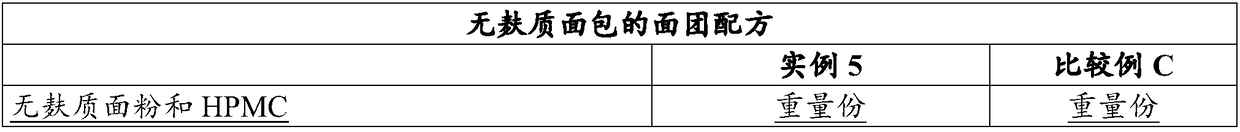

example 5 and comparative example C-E

[0049] The recipes for preparing the doughs of Example 5 and Comparative Example C are listed in Table 3 below. . The sodium carboxymethylcellulose listed in Table 3 below has a degree of substitution of 0.9 and a viscosity of 3000 to 4000 mPa·s in a 1% by weight aqueous solution at 20°C using a Brookfield LVT viscometer, 3 No. rotor measured at 30 rpm.

[0050] table 3

[0051]

[0052]

[0053] The dough preparation recipes for Comparative Examples D and E are listed in Table 4 below.

[0054] Table 4

[0055]

[0056] As described above in Examples 1-4, equal weight doughs were prepared from the recipes of Example 5 and Comparative Examples C, D, and E, except that the proofing time of the dough in Example 5 was 75 minutes and adjusted for Comparative Examples C, D and E. Proof times in D and E to produce breads of Example 5 and Comparative Examples C, D and E, all of similar volume. Afterwards, the dough pieces are baked as described above.

[0057] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com