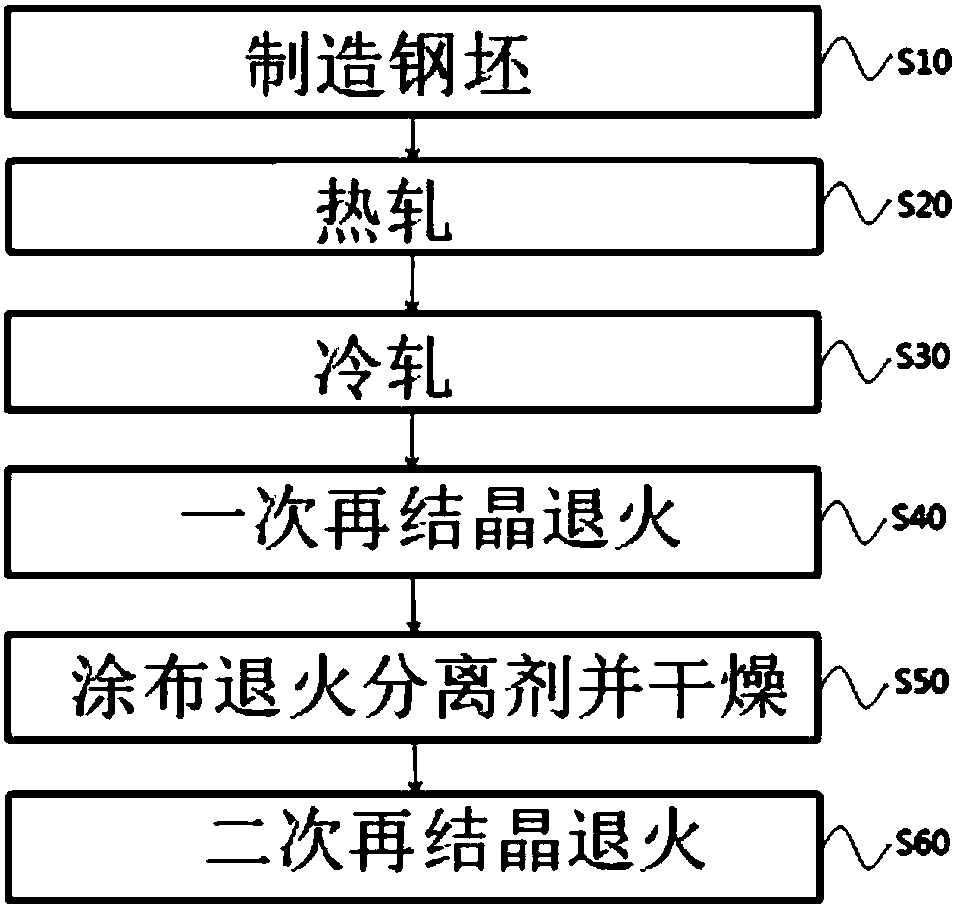

Method for manufacturing grain-oriented electrical steel sheet

A technology of oriented electrical steel sheets and manufacturing methods, which is applied in the direction of manufacturing tools, metal material coating processes, coatings, etc., can solve the problems of the difference in the formation of the base coating layer without glass, and can not be commercialized, so as to improve the iron loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0151] Manufactured by weight % including 3.2% Si, 0.055% C, 0.12% Mn, 0.026% Al, 0.0042% N and 0.0045% S and added Sn, Sb and Billets of P. After the slab of the slab composition system 1 was hot-rolled to manufacture a 2.8 mm hot-rolled sheet, the hot-rolled sheet was annealed and pickled, and then cold-rolled to a final thickness of 0.23 mm.

[0152] 【Table 1】

[0153]

[0154] The cold-rolled steel plate is then subjected to recrystallization annealing once, and maintained at a soaking temperature of 875°C in an atmosphere of a mixed gas of 74% by volume of hydrogen, 25% by volume of nitrogen and 1% by volume of dry ammonia. Hold for 180 seconds to carry out decarburization and nitriding treatment. At this time, the temperatures of the heating zone, the first soaking zone, the second soaking zone and the third soaking zone are adjusted to 800 to 900°C. In addition, adjust the dew point of the heating zone to 48°C, adjust the dew point of the first soaking zone to 52°...

Embodiment 2 and comparative example 1 to 16

[0157] Replace the billet with the slab composition system organized in the following Table 2, and the dew points of the heating zone, the first soaking zone, the second soaking zone and the third soaking zone in the first annealing process are shown in Table 2 Adjusted as sorted in , and the annealing separator was adjusted as sorted in Table 2 below to manufacture a grain-oriented electrical steel sheet.

[0158] 【Table 2】

[0159]

[0160]

[0161] Figure 6 A photograph taken with a field emission transmission electron microscope (FE-EPMA) of the side surface of a cold-rolled sheet after performing one recrystallization annealing is shown. It was confirmed that the oxide layer was formed to a thickness of about 5 μm.

experiment example

[0163] The results are summarized in Table 3 below by measuring the roughness, gloss, iron loss and magnetic flux density of the grain-oriented electrical steel sheets produced in Examples 1, 2 and Comparative Examples 1 to 16. The glossiness was defined as the glossiness, and the amount of light reflected from the surface at a reflection angle of 60° was measured based on the specular glossiness of 1,000.

[0164] 【table 3】

[0165]

[0166]

[0167] As shown in Table 3, in the case of Example 1 and Example 2, the thickness of the oxide layer was formed thinner than that of the comparative example, and the removal of the forsterite layer during secondary recrystallization annealing was easy. Therefore, it is possible to obtain a metallic luster type grain-oriented electrical steel sheet which is easy to move magnetic domains. On the other hand, it was confirmed that the amount of oxygen in the oxide layer was similar to that of the comparative example and the decarburi...

PUM

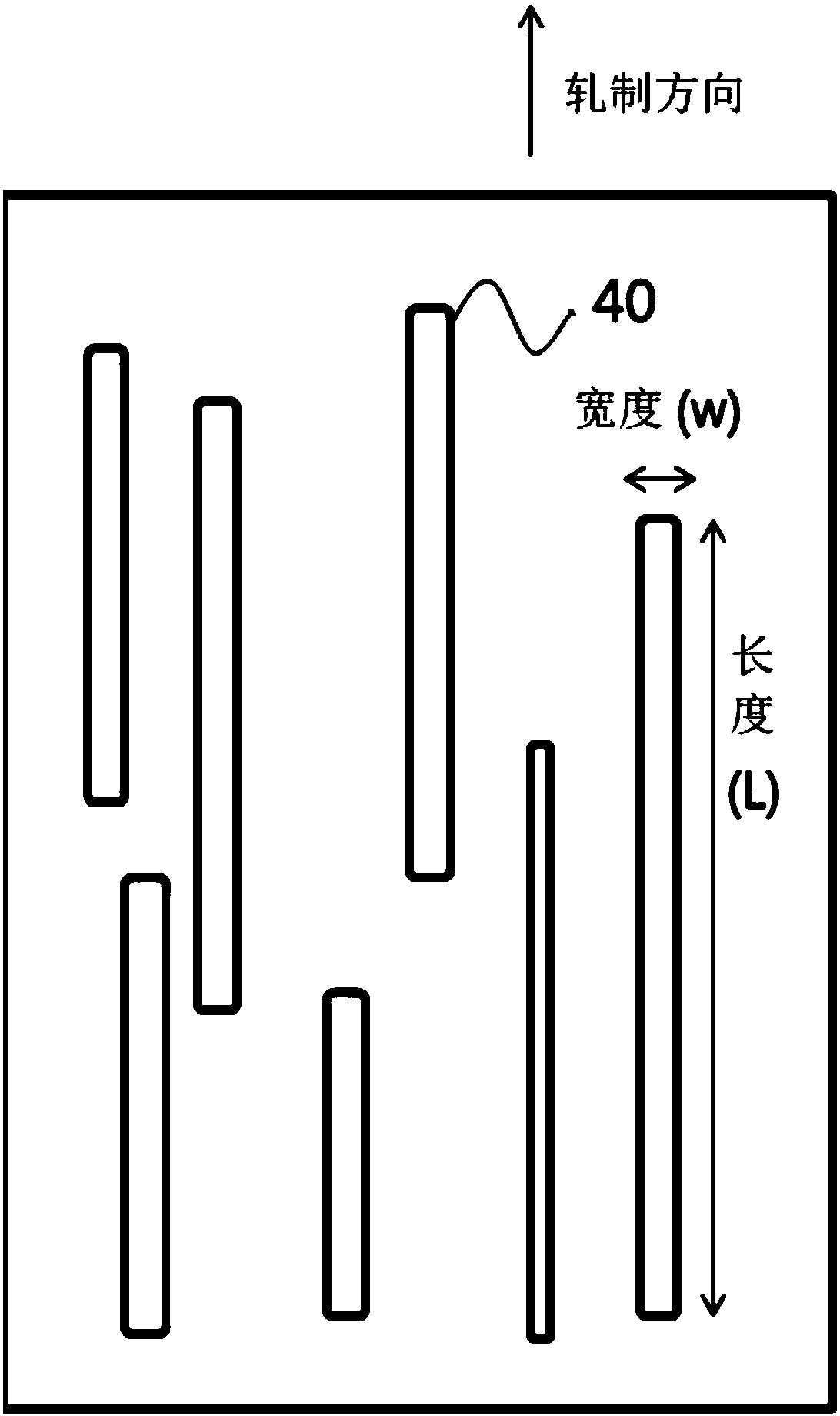

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com