Energy-saving environment-friendly dust settling and dust removal equipment

A dust removal equipment, energy saving and environmental protection technology, applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of wasting water resources, environmental pollution, etc., and achieve the effect of saving energy, protecting the environment and ensuring thoroughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

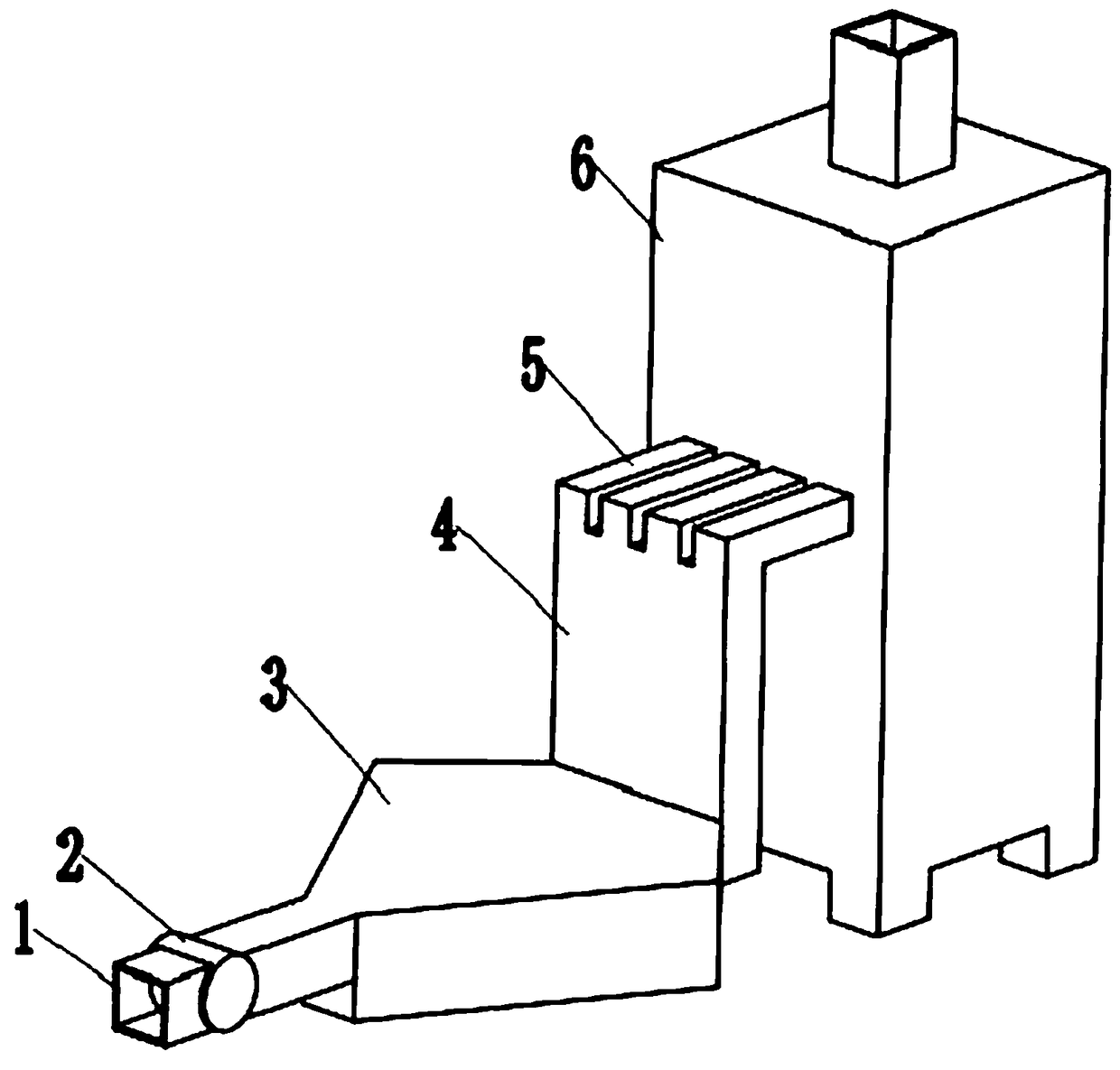

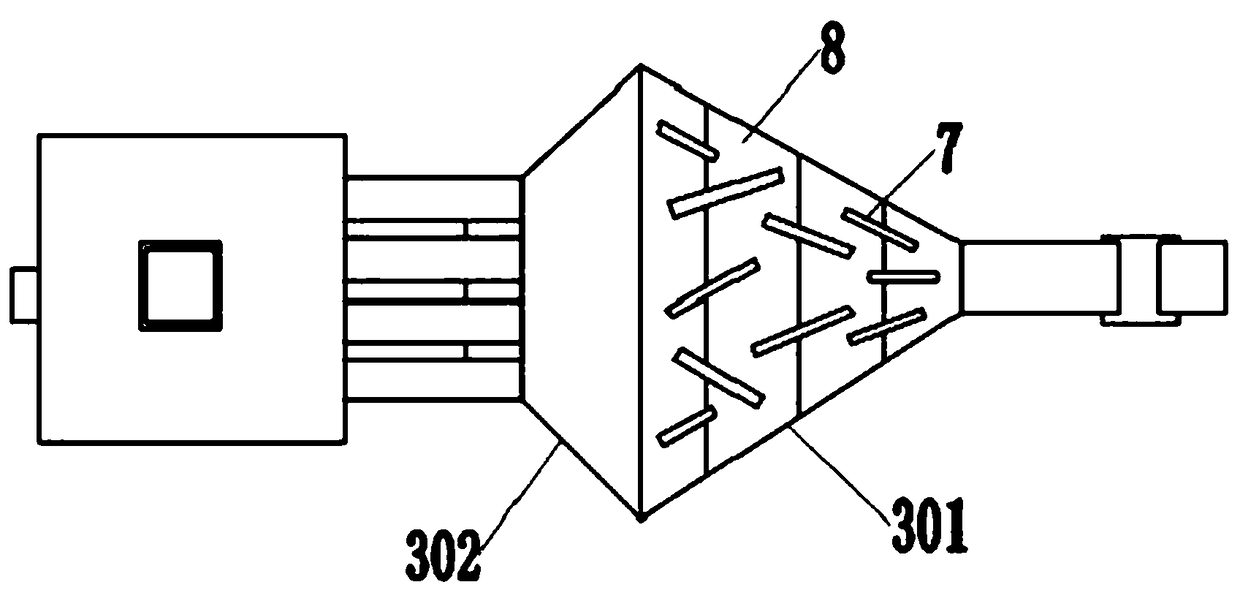

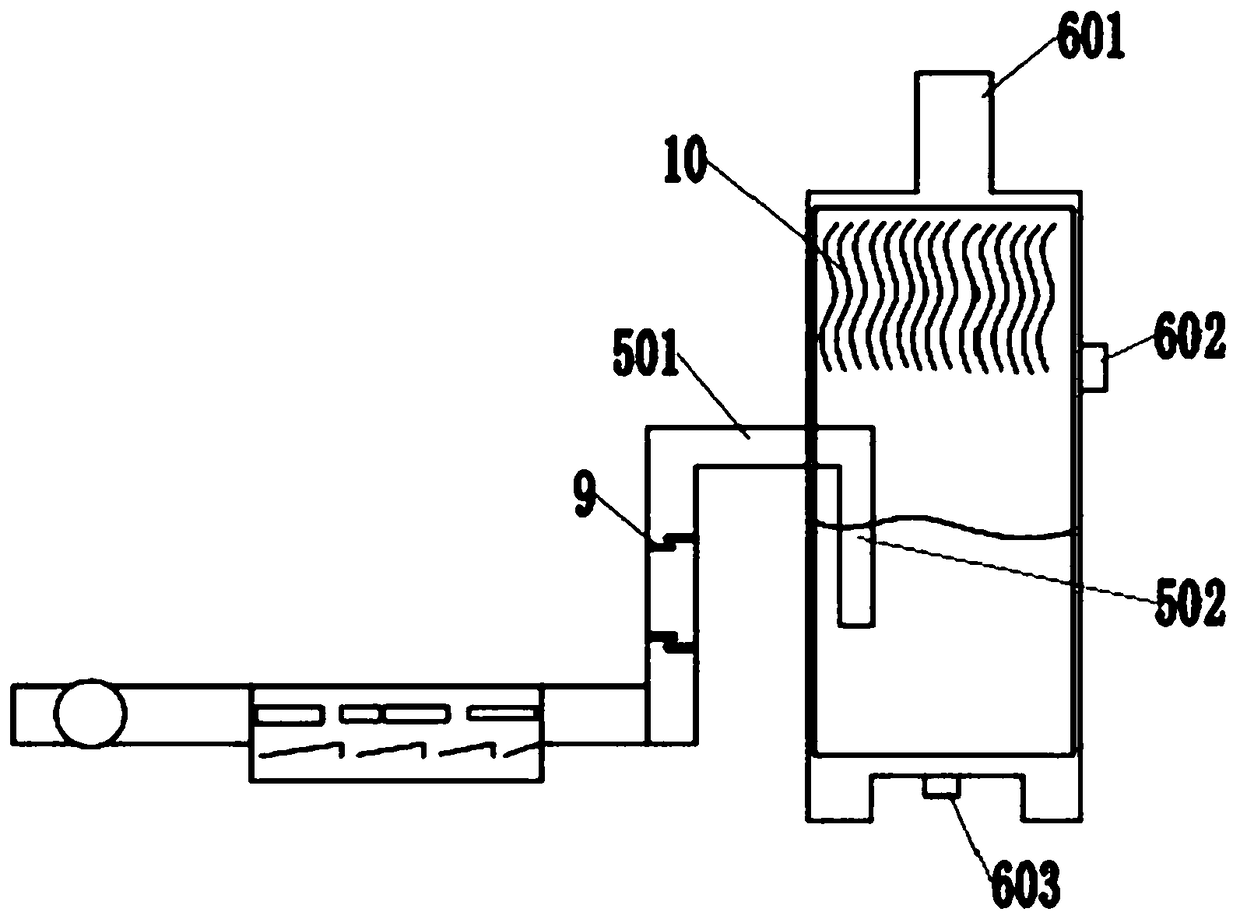

[0026] See Figure 1-4 , The invention provides a technical solution: an energy-saving and environmentally friendly dust-reducing and dust-removing equipment, including a dust inlet pipe 1, a first-level dust reduction chamber 3, a second-level dust-reduction chamber 4, an air duct 5, and a scrubbing chamber 6, the dust exhaust pipe 1 and The first-level dust reduction chamber 3 is connected. The first-level dust reduction chamber 3 is divided into a gas dividing chamber 301 and a gas collecting chamber 302. The gas dividing chamber 301 is connected to the gas collecting chamber 302. The upper layer of the gas dividing chamber 301 is provided with a dividing plate 7 The lower layer of the air distribution chamber 301 is provided with a dust reduction plate 8, the secondary dust reduction chamber 4 is connected to the air collection chamber 302, and the air duct 5 is respectively connected to the secondary dust reduction chamber 4 and the scrubbing chamber 6. The washing chamber...

Embodiment 2

[0029] An energy-saving and environmentally friendly dust-reducing and dust-removing equipment, comprising a dust inlet pipe 1, a first-level dust reduction chamber 3, a second-level dust-falling chamber 4, an air duct 5, and a gas washing chamber 6. The dust exhaust pipe 1 is connected to the first-level dust-reduction chamber 3, and The first-level dust reduction chamber 3 is divided into a gas dividing chamber 301 and a gas collecting chamber 302. The gas dividing chamber 301 is connected to the gas collecting chamber 302. The upper layer of the gas dividing chamber 301 is provided with a dividing plate 7, and the gas dividing chamber 301 The lower layer is provided with a dust reduction plate 8, the secondary dust chamber 4 is connected with the air collection chamber 302, the air duct 5 is respectively connected with the secondary dust chamber 4 and the air washing chamber 6, and the air washing chamber 6 is provided with dehydration Plate 10, the upper end of the scrubbing...

Embodiment 3

[0031] An energy-saving and environmentally friendly dust-reducing and dust-removing equipment, comprising a dust inlet pipe 1, a first-level dust reduction chamber 3, a second-level dust-falling chamber 4, an air duct 5, and a gas washing chamber 6. The dust exhaust pipe 1 is connected to the first-level dust-reduction chamber 3, and The first-level dust reduction chamber 3 is divided into a gas dividing chamber 301 and a gas collecting chamber 302. The gas dividing chamber 301 is connected to the gas collecting chamber 302. The upper layer of the gas dividing chamber 301 is provided with a dividing plate 7, and the gas dividing chamber 301 The lower layer is provided with a dust reduction plate 8, the secondary dust chamber 4 is connected with the air collection chamber 302, the air duct 5 is respectively connected with the secondary dust chamber 4 and the air washing chamber 6, and the air washing chamber 6 is provided with dehydration Plate 10, the upper end of the scrubbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com