Novel environmental-protection dust removal device

A dust removal device and environmental protection technology, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, can solve the problems of small dust concentration range, poor explosion-proof and moisture-proof performance, and increased maintenance workload. Low bag wear rate, low cost, and the effect of extending the life of the filter bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

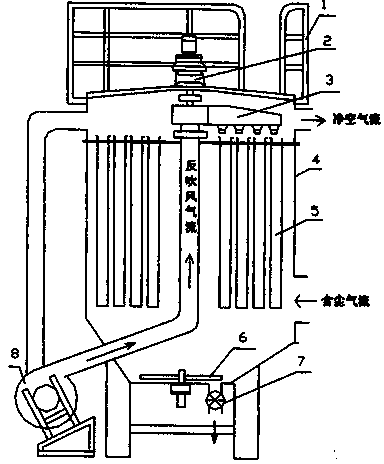

[0011] Example 1: see figure 1 , a new environmental protection dust removal device, the new environmental protection dust removal device includes an upper box, a middle box 4, a filter assembly, a dust removal system, an ash hopper part, and an ash discharge system, and the filter cloth bag is arranged in the middle box. The lower part of the box is equipped with an ash discharge system, wherein the upper box includes a clean air chamber, an inspection cover, and a clean air outlet; the middle box includes a perforated plate, an air inlet, and an inspection door; Observation port; the filter assembly includes a filter bag 5, a bag frame, and a bayonet; the dust removal system includes a blowing pipe 3, a high-pressure reverse blower 8, and a reverse blowing rotary mechanism 2; the ash discharge system includes a dust discharge lock 7, a rotary Dust scraping device 6; the auxiliary equipment includes guardrails and ladders 1, etc., the dust-laden airflow enters the middle bo...

Embodiment 2

[0012] Example 2: see figure 1 , as an improvement of the present invention, the ash hopper box adopts a flat-bottomed ash hopper structure. The ash discharge system consists of a scraper mechanism and an ash discharge locker. The dust falling into the ash hopper is forcibly scraped to the ash unloading port by the ash scraper, and then discharged through the ash unloader, which destroys the condition of the dust arching, not only prevents the dust from forming arches, but also reduces the efficiency of the whole machine. height, so that the dust can be smoothly discharged from the dust collector.

Embodiment 3

[0013] Example 3: As an improvement of the present invention, the dust removal system adopts differential pressure control. When the resistance of the filter bag reaches the set value of 1200Pa, the dust removal system starts to clean the dust. When the value is 800Pa, the cleaning system stops working.

[0014] The working principle is as follows: In the system design, reverse air flow and back blowing are adopted. The high-pressure dust-cleaning airflow generated by the high-pressure fan passes through the filter cloth in the opposite direction to the filter airflow, so that the dust on the surface falls off and falls into the ash hopper. This dust cleaning method distributes the airflow evenly on the entire filter bag, the airflow does not contain water, and the wear rate of the filter bag is low, which can prolong the life of the filter bag and is not affected by the temperament. It does not need to provide compressed air and can independently form a dust removal syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com