Odor treatment system

A treatment system and odor technology, which are applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of reducing the effect of treatment liquid on odor treatment, the influence of equipment service life, and the effect of odor treatment. The effect of improving the effect, treating it thoroughly, and promoting the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

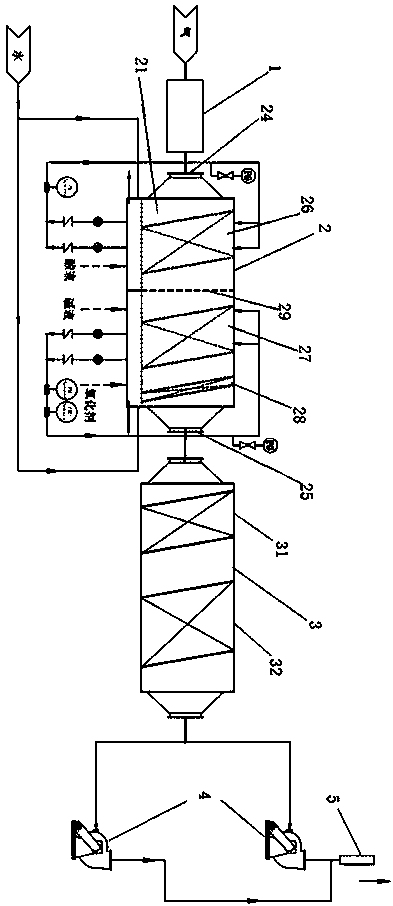

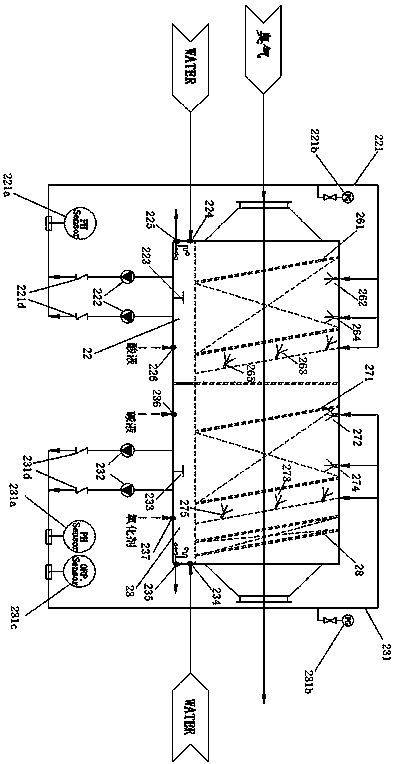

[0033] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0034] Such as figure 1 , shown in 2, a kind of odor treatment system is characterized in that: comprises heating device 1, cross-flow washing tower 2, dry degassing tower 3, blower fan 4 and the gas discharge part that is used to discharge the gas after treatment 5; the five are connected in sequence through pipelines.

[0035] The heating device 1 is arranged before the cross-flow scrubber 2, and the purpose of setting is to increase the reactivity of the odor molecules by heating, thereby promoting the reaction of the odor with the odor treatment liquid after entering the cross-flow scrubber, and making the odor The treatment of gas is mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap