Combined tower type thin-wall ring-shaped metal rubber part stamping die with inner reinforcement rib plates and operation method thereof

A technology for reinforcing rib plates and metal rubber, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as inability to withstand high forming pressure, failure to prepare metal rubber parts, inability to form thin-walled male molds, etc., and achieve high stability. stability, uniform force, and ensure the effect of external dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

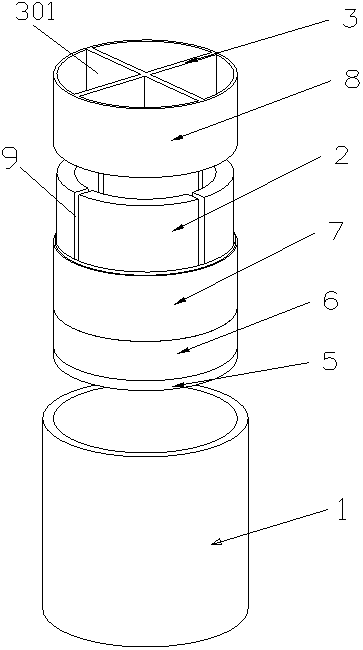

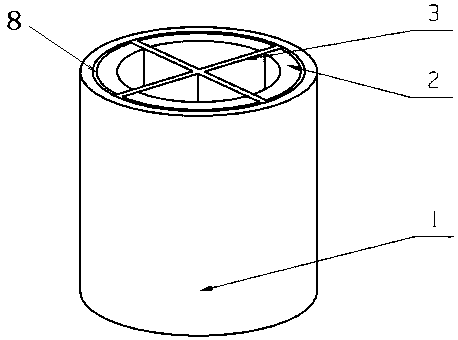

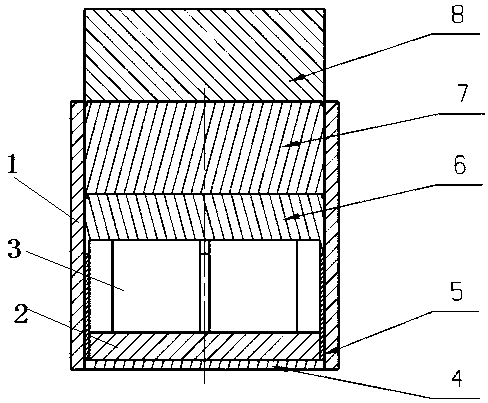

[0021] The stamping die of the combined tower type and thin-walled ring-shaped metal rubber parts with internal reinforcing ribs of the present invention includes a cylindrical female mold 1 and a cushion block 4 fixed on the bottom surface of the female mold. There is a cylindrical mandrel 2, and the outer periphery of the cylindrical mandrel is wound with a spirally coiled metal wire blank 5, and four sinking grooves 9 are evenly opened on the wall of the cylindrical mandrel 2, and the outer periphery of the cylindrical mandrel and the A plurality of cylindrical male molds 6, 7, 8 that can move axially along the cylindrical mandrel are set between the inner walls of the female molds, and the inner walls of the cylindrical male molds are fixed with reinforcing ribs 3 arranged crosswise, The reinforcing ribs 3 are limited in the sinker 9 and can move axially along the cylindrical mandrel.

[0022] Further, the above-mentioned reinforcing rib 3 is composed of two rectangular pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com