Electric vehicle high-voltage interlocking loop and open circuit positioning method

A high-voltage interlocking circuit, electric vehicle technology, applied in electric vehicles, measuring electricity, power-consuming devices, etc., can solve the problem of inability to accurately locate the fault of high-voltage connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

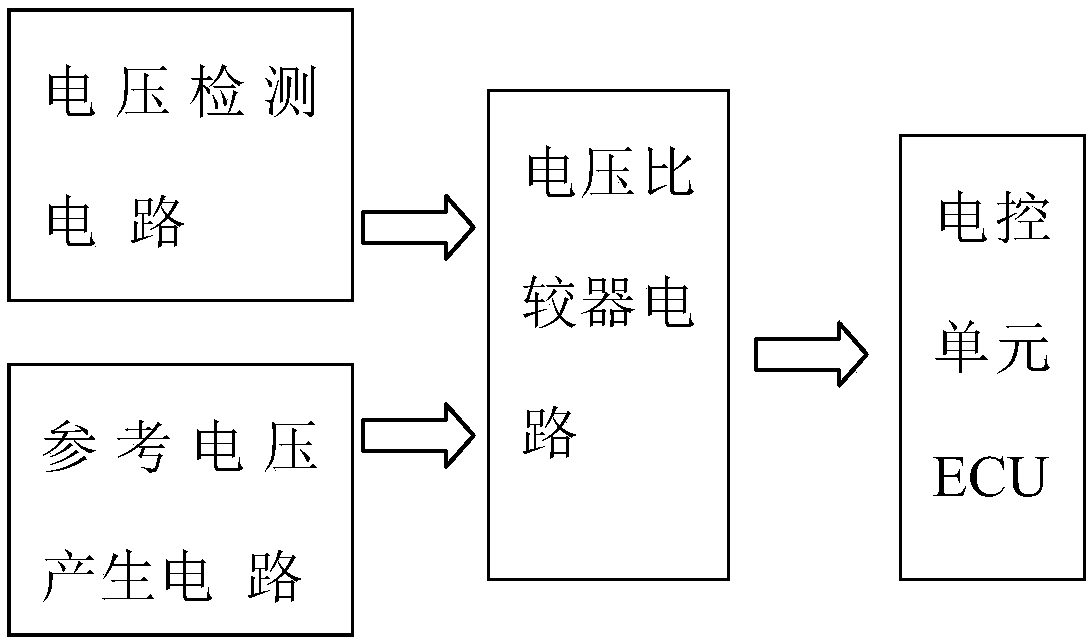

[0048] Such as figure 1 As shown, a high-voltage interlock circuit of an electric vehicle, the high-voltage interlock circuit is a low-voltage electrical connection circuit independent of the high-voltage circuit of the electric vehicle, including a voltage detection circuit, a reference voltage generation circuit, a voltage comparator circuit and an electronic control unit ECU; the detection voltage of the voltage detection circuit and the reference voltage of the reference voltage generation circuit are used as the input signal of the voltage comparator in the voltage comparator circuit, and the output signal of the voltage comparator is used as the input signal of the electronic control unit ECU.

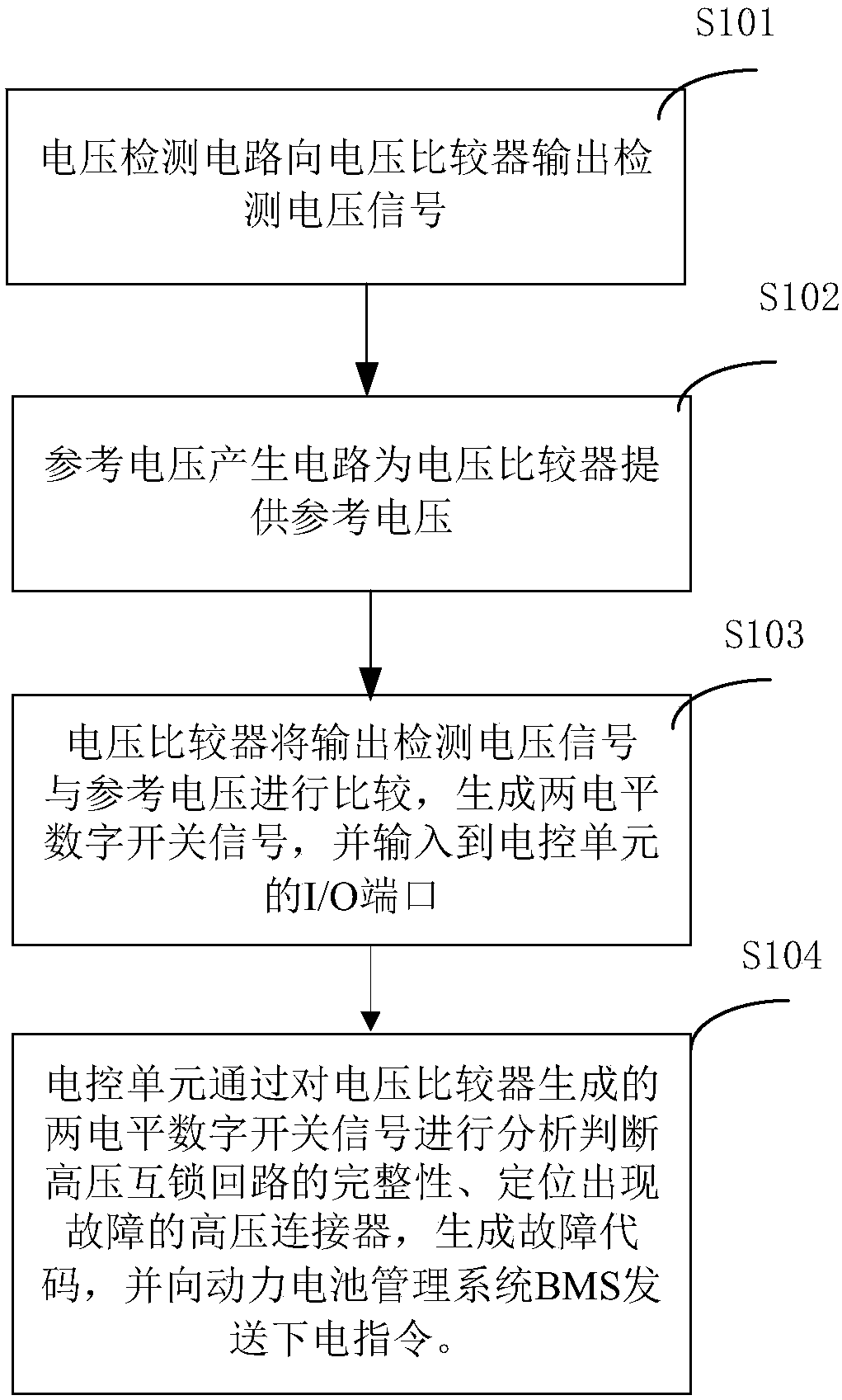

[0049] figure 2 It shows the flow chart of the high-voltage interlock open circuit positioning method of the high-voltage interlock circuit of the electric vehicle provided by the first embodiment of the present invention, and its specific steps are as follows:

[0050] In step...

Embodiment 2

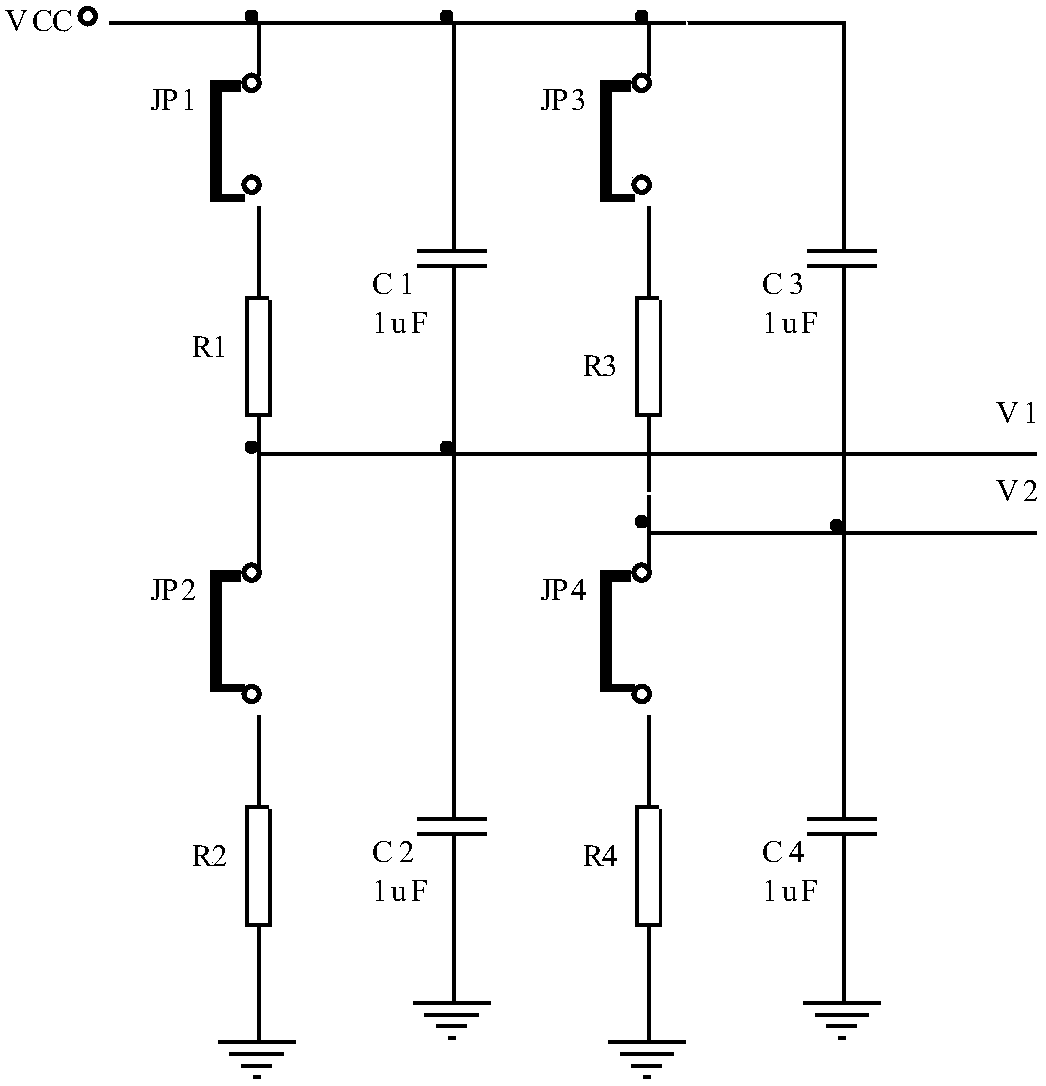

[0057] On the basis of the above-mentioned first embodiment, further optimization is performed, and the positioning detection is mainly performed on the four high-voltage connectors in the electric vehicle.

[0058] Such as image 3 As shown, the voltage detection circuit includes a first-stage voltage detection circuit and a second-stage voltage detection circuit connected in parallel, one end of the first-stage voltage detection circuit and the second-stage voltage detection circuit are electrically connected to the low-voltage power supply Vcc, and the other ends are grounded .

[0059] The voltage detection circuit includes a first-stage voltage detection circuit and a second-stage voltage detection circuit connected in parallel, one end of the first-stage voltage detection circuit and the second-stage voltage detection circuit are both electrically connected to the low-voltage power supply, and the other ends are both grounded;

[0060] The first-stage voltage detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com