Walking device of slewing bearing

A technology of slewing support and walking device, which is applied in the direction of steering mechanism, mechanical steering gear, transportation and packaging, etc. It can solve the problems of large operation blind area, inaccurate compensation angle, large steering radius, etc., and achieve equipment cost saving, convenient steering and labor saving , the effect of small turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

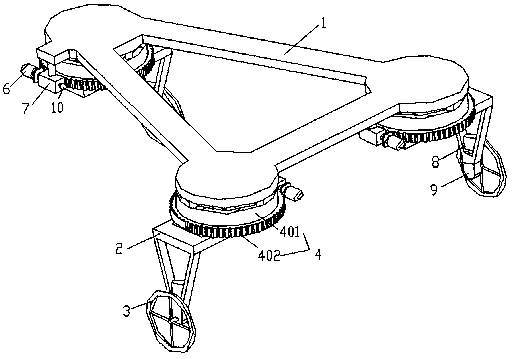

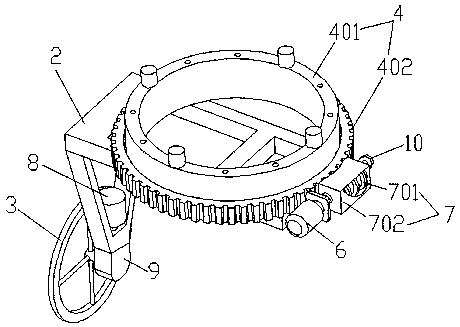

[0021] Such as figure 1 , figure 2 As shown, a slewing support walking device provided by the present invention includes a vehicle frame 1 and at least three outrigger structures. In this embodiment, the number of outrigger structures is three, and the three outrigger structures are distributed in an isosceles triangle. The outrigger structure includes a wheel 3 and a wheel bracket 2, and the wheel bracket 2 is connected to the vehicle frame 1 through a slewing support 4 to realize the rotatable connection between the wheel bracket 2 and the vehicle frame 1. The slewing support 4 includes a relatively rotatable outer ring 402 and an inner ring 401, rolling elements are arranged between the outer ring 402 and the inner ring 401, and transmission teeth are arranged on the outer surface of the outer ring 402, and the transmission teeth pass through the teeth The transmission mechanism 7 is connected in a combined manner, and the transmission mechanism 7 is connected to the rota...

Embodiment 2

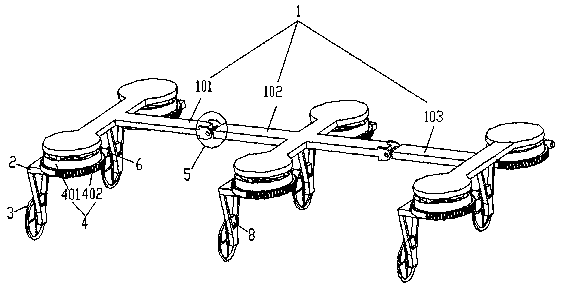

[0024] The structure principle of the slewing support walking device shown in this embodiment is basically the same as that of Embodiment 1. The difference is that the vehicle frame 1 in this embodiment is composed of three frame units that are rotatably connected. Specifically, as image 3 As shown, that is, the first frame unit 101, the second frame unit 102 and the third frame unit 103 are connected through the horizontal rotation pin 5, so as to realize the horizontal rotation between adjacent frame units, The bottom of the first frame unit 101, the second frame unit 102 and the third frame unit 103 are provided with two outrigger structures, the two outrigger structures are symmetrical about the center of the corresponding frame unit, and the outrigger structures also include wheels 3 and the wheel bracket 2, the wheel bracket 2 is connected to the corresponding vehicle frame unit through the slewing support 4, and the slewing support 4 is also driven by the slewing drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com