Straddle type monorail track beam, manufacturing method thereof and monorail system

A straddle-type monorail and track beam technology, which is applied in the field of rail transit, can solve problems such as concrete pouring at wet joints, difficulty in vibration, impact on driving comfort, and increased difficulty of construction, so as to achieve simple structure and enhance overall stability Sexuality, the effect of less post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

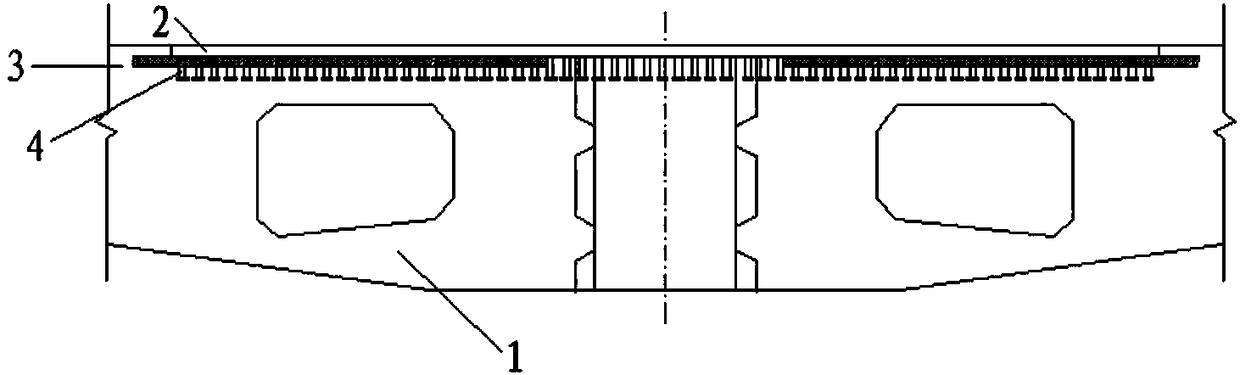

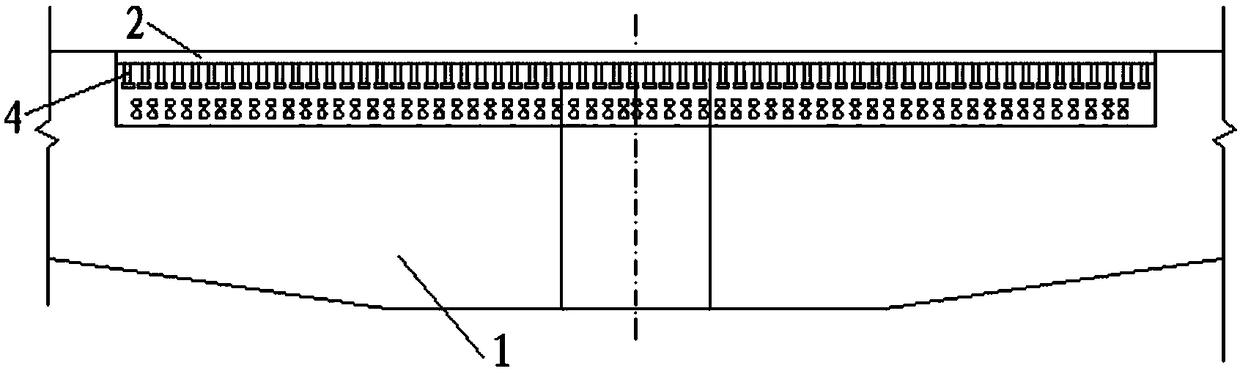

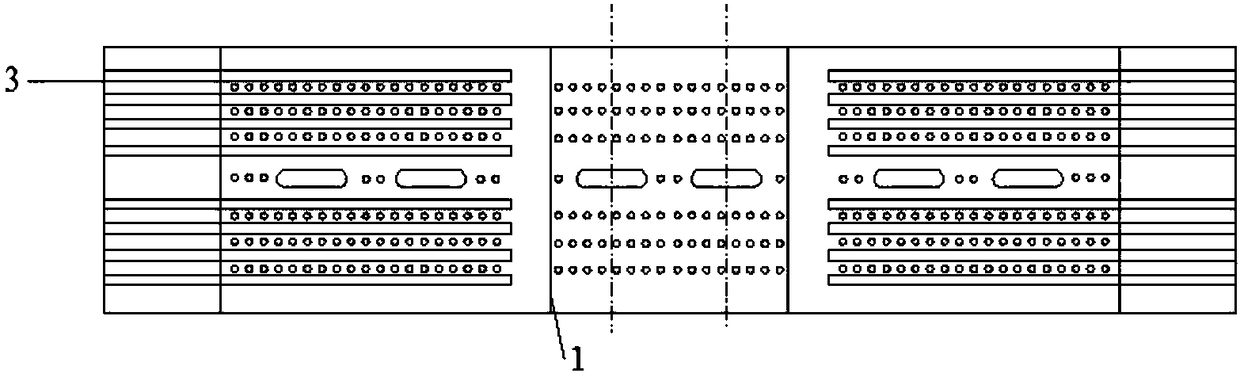

[0035] Figure 4 Shown is the top sectional view at the wet joint of the straddle type monorail track beam of the present invention; as Figure 4 and Figure 5 As shown, the straddle-type monorail track beam includes: a plurality of corrugated pipes and a plurality of steel strands 5; so that the end of the corrugated pipe is not on the same cross-section of the track beam 1; the corrugated pipe in the track beam 1 of the adjacent span is connected with the corrugated pipe in the wet joint at the pier, and the steel strand 5 passes through the adjacent span The bellows in the track beam 1 and the bellows in the wet joint; and the ends of the steel strands 5 are respectively anchored at the top surface of the adjacent span track beam 1 .

[0036] Specifically, in Figure 4 and Figure 5 In order to facilitate the display of strand 5, in Figure 4 and Figure 5 The corrugated pipe is omitted in , but the direction of the corrugated pipe is consistent with the steel strand ...

Embodiment 2

[0044] like Image 6 As shown, the present invention also provides a method for manufacturing a straddle type monorail track beam, including: S1, pre-embed a plurality of bellows in the top plate of the track beam 1, and the ends of the bellows are arranged in a staggered manner on the track at the roof of the beam 1; S2, pouring wet joints at the pier, and pre-embedding multiple bellows in the wet joints; and connecting the bellows in the track beam 1 with the bellows in the wet joints; The wire is inserted into the bellows in the track beam 1 of the adjacent span and the bellows in the wet joint to connect the track beam 1 of the adjacent span and the wet joint; The ends of the wires 5 are respectively anchored at the top surfaces of the track beams 1 of adjacent spans. And, the step S3 further includes: filling the gap between the corrugated pipe and the steel strand.

[0045] Specifically, the bellows are pre-embedded in the top plate of the track beam 1, that is, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com