Cement concrete pavement structure of tunnel

A cement concrete and pavement structure technology, which is applied to roads, roads, pavement details, etc., can solve the problems of tunnel cement pavement anti-slip attenuation, tunnel water accumulation, etc., and achieve improved drainage efficiency, small building area, and reduced friction sound Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

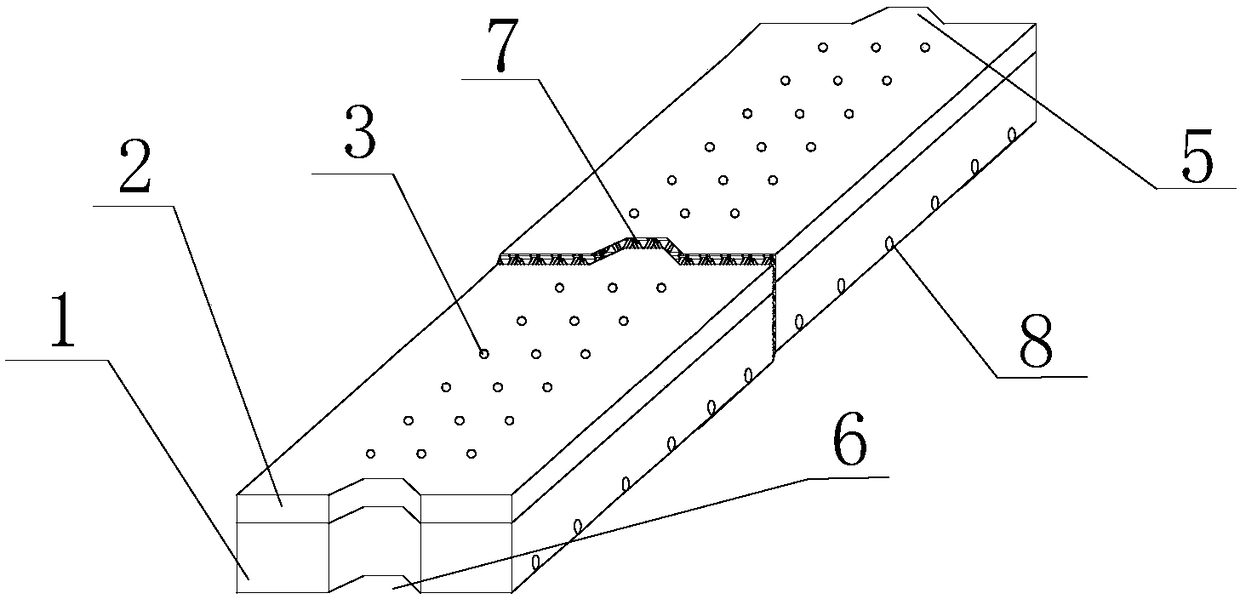

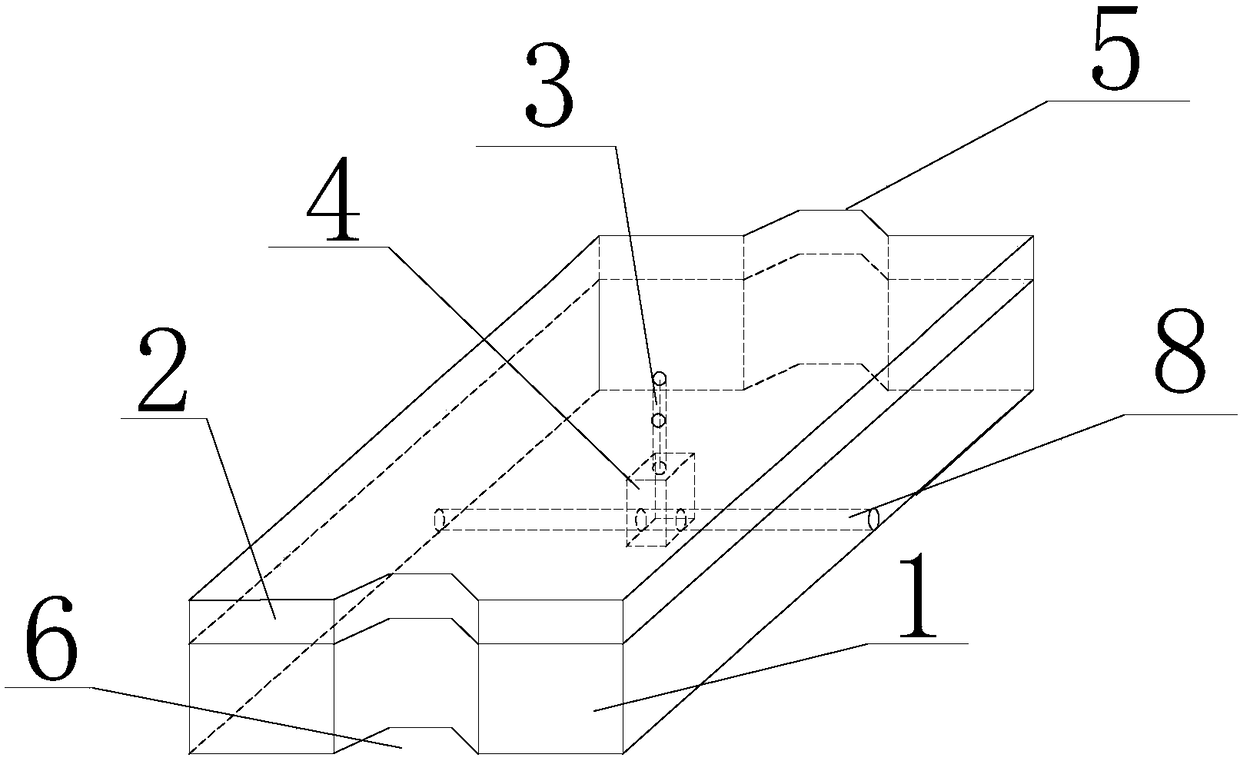

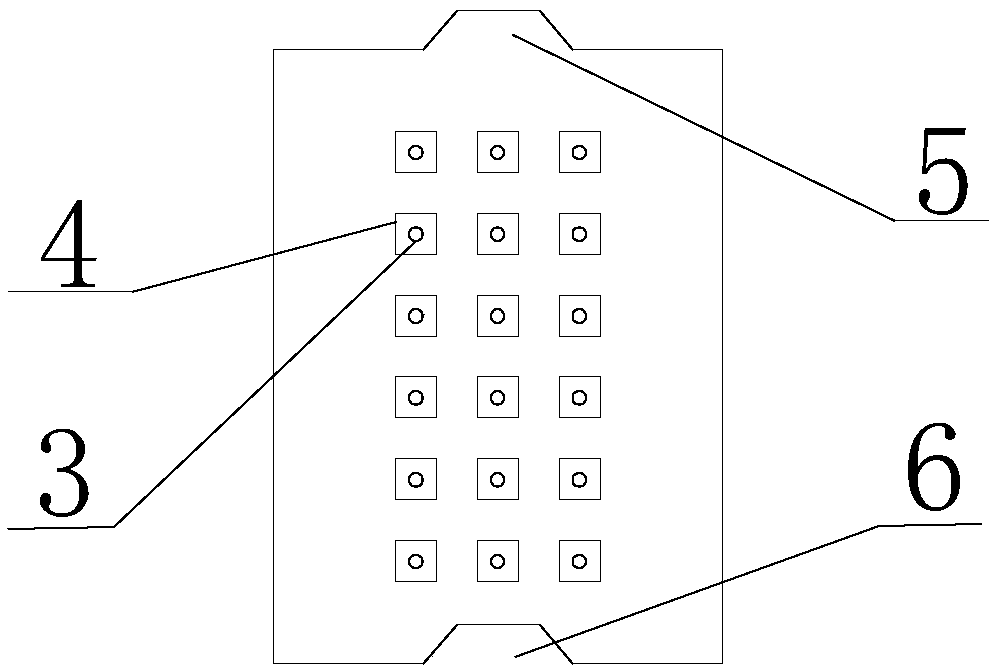

[0025] Such as Figure 1 to Figure 6 As shown, a tunnel cement concrete pavement structure includes a prefabricated cement concrete surface slab 1, the upper end of the prefabricated cement concrete surface slab 1 is provided with a rough anti-skid surface layer 2, and the prefabricated cement concrete surface slab 1 is provided with a plurality of Through the hole 3, the lower end of the prefabricated cement concrete surface layer 1 is provided with a hollow box 4, and the through hole 3 is connected with the hollow box 4.

[0026] The two ends of the prefabricated cement concrete surface slab 1 are provided with protrusions 5 and grooves 6, which are used for block connection, and asphalt and other joint fillers 7 can be added to the joint gaps, and asphalt joint fillers can also be added to the remaining joints ;

[0027] The lower end of the prefabricated cement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com