A hollow triangular arc-shaped retaining wall

A hollow and retaining wall technology, applied in construction, artificial islands, infrastructure engineering, etc., can solve the problems of high labor and material costs, difficult quality control, high material consumption, etc., to achieve easy quality control, reasonable force, and artificial low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

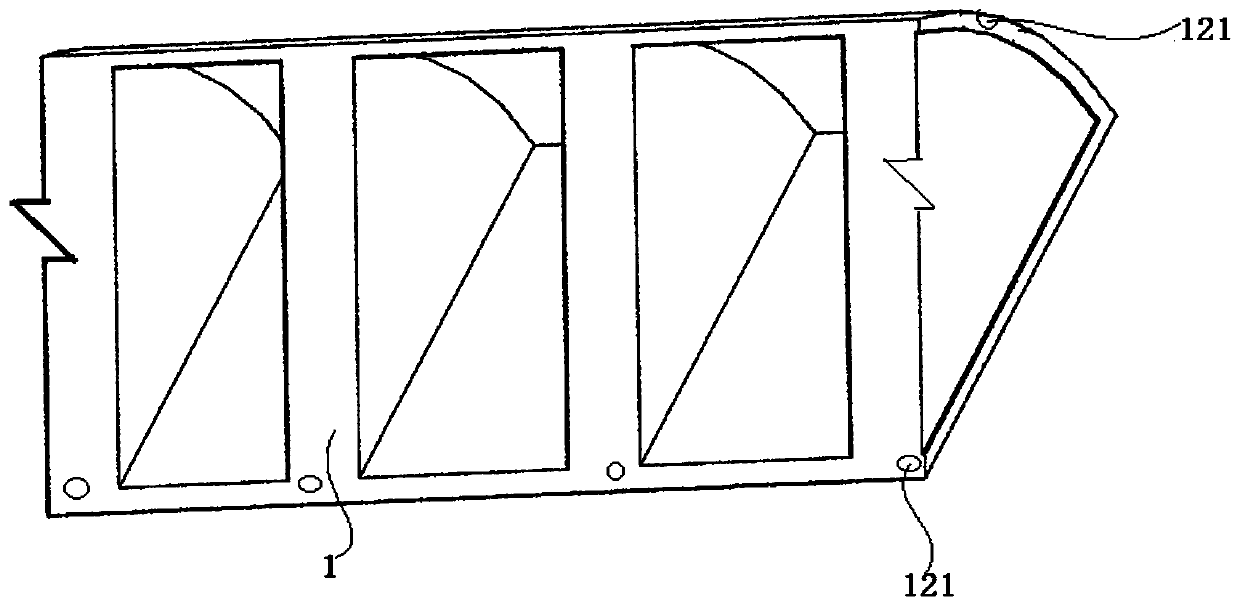

[0032] A hollow triangular arc-shaped retaining wall mainly includes n hollow triangular arc-shaped retaining wall main bodies 1 , m support piles 2 and rigid connectors 3 . n>1. m>1. n and m are integers. m=2n.

[0033] The main body 1 of the hollow triangular arc-shaped retaining wall is located on one side of the slope 5 .

[0034] Further, there is filled soil 4 between the hollow triangular arc-shaped retaining wall main body 1 and the side slope 5 . The filling 4 is construction waste.

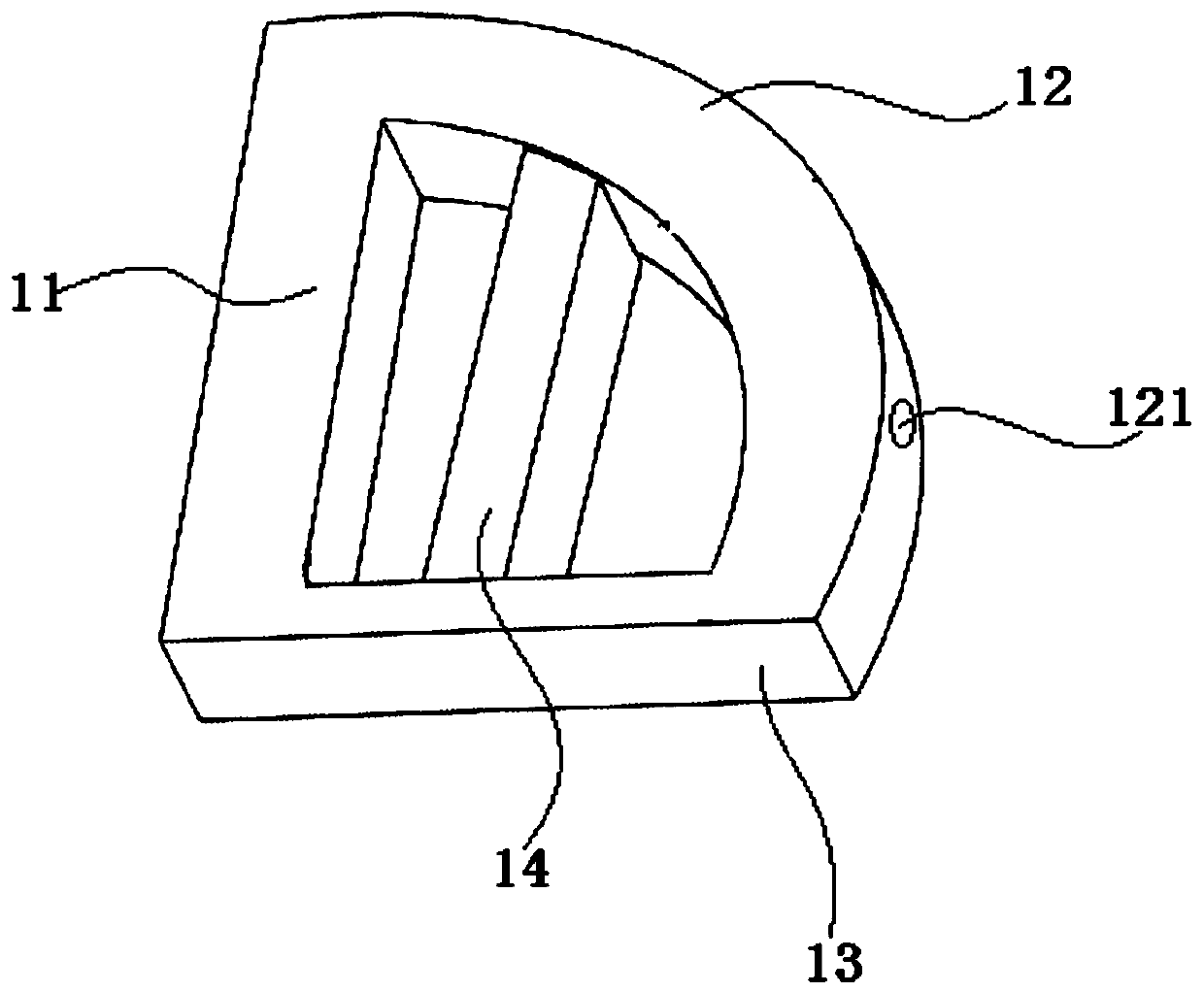

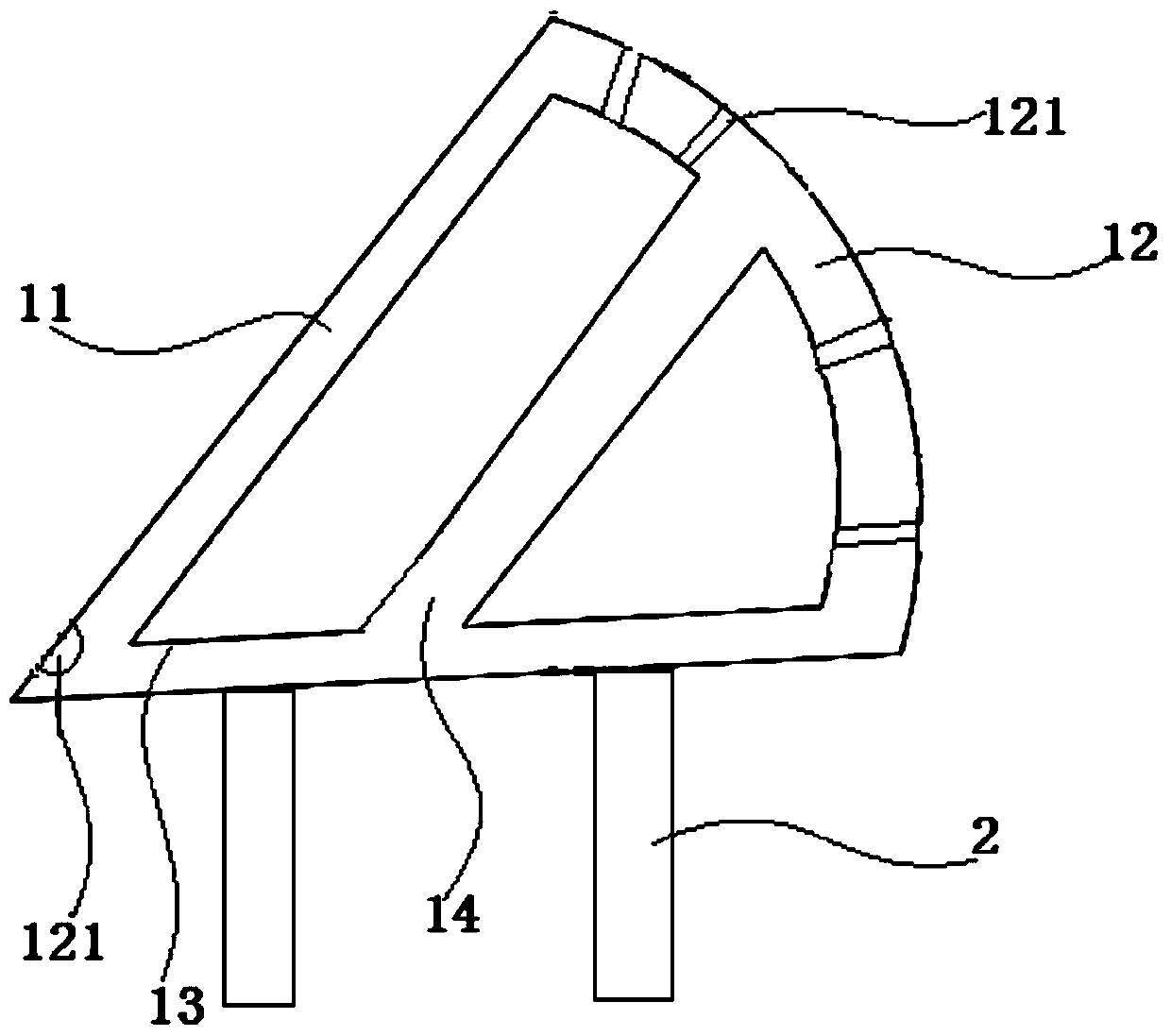

[0035] The main body 1 of the hollow triangular arc-shaped retaining wall mainly includes a hollow retaining wall block I11 , a hollow retaining wall block II12 , a hollow retaining wall block III13 and a support column 14 .

[0036] The hollow retaining wall block I11 is a hollow cuboid.

[0037] The hollow retaining wall block II12 is a hollow arc-shaped three-dimensional structure. There are several drainage holes 121 on the block II12 of the hollow retaining wall. The drainag...

Embodiment 2

[0052] A construction method for a hollow triangular arc-shaped retaining wall, comprising the following steps:

[0053] 1) Retaining wall design;

[0054] Determine the type of hollow triangular arc-shaped retaining wall main body 1 and support pile 2 according to the geological conditions and slope soil conditions, mainly including the cross-sectional form of the hollow triangular arc-shaped retaining wall main body 1 and support pile 2, prefabricated materials, reinforcement conditions and Support pile 2 buried depth.

[0055] 2) Determine the foundation and drive into the supporting piles; the main steps are as follows:

[0056] 2.1) Pile positioning;

[0057] 2.2) Inserting the prefabricated pile into the joint grouting method through static pressure or drilling (that is, drilling through a drilling rig, then inserting the prefabricated pile into the drilled hole, and then pouring concrete around the drilled hole so that the pile and soil are in close contact) to drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com