Attached type lifting scaffold

A lifting scaffolding and attachment technology, which is applied to the scaffolding supported by the house structure, the house structure support, the house structure support, etc., can solve the problems of the scaffold body, such as heavy weight, unsuitable installation, and no safety guarantee, so as to achieve the bearing capacity and effect Significant, scientific and reasonable frame structure, avoiding deformation and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

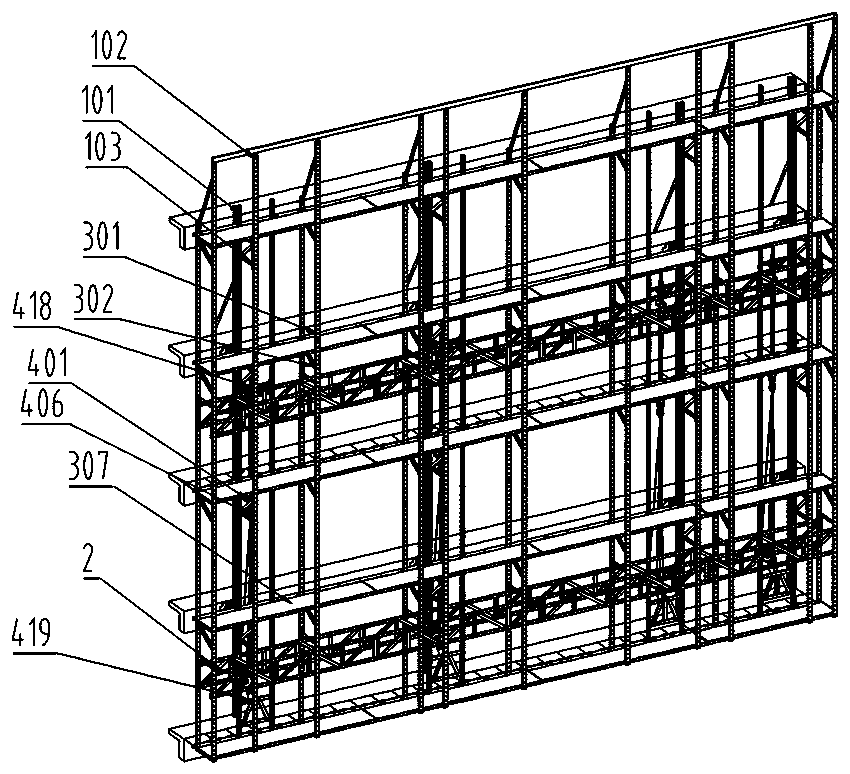

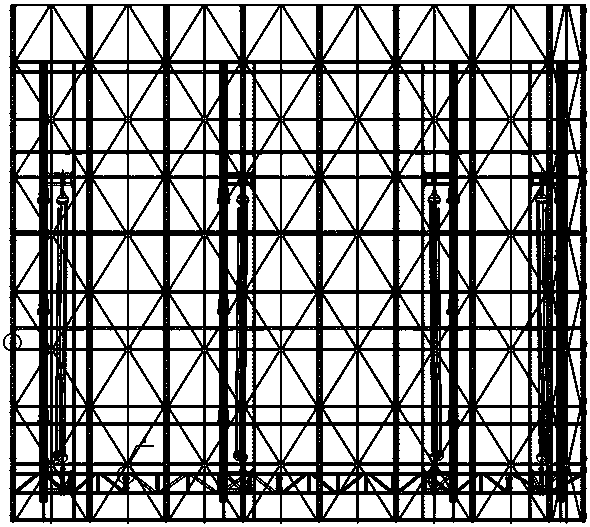

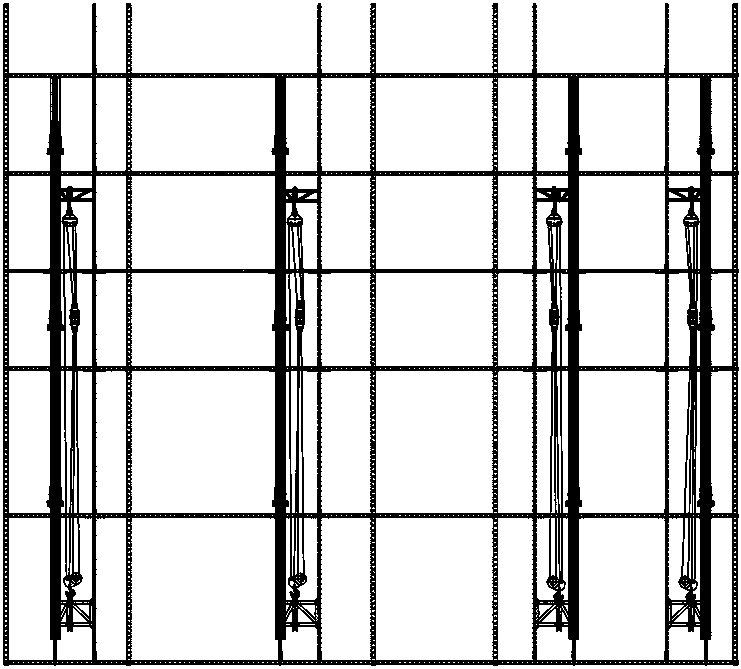

[0081] Embodiment 1: a kind of attached lifting scaffold, such as Figure 1-52 As shown, it includes a vertical main frame 1, a horizontal support truss 2, a frame frame mechanism 3, a lifting mechanism 4 and an attachment support mechanism 5;

[0082] The vertical main frame 1 includes guide rails 101 and main frame poles 102 that are evenly arranged vertically, and is connected by a "Z" type support 103 between the guide rails 101 and the main frame poles 102. The guide rails 101 include guide rails 101 poles and two relative The guide rail channel steel 104 installed on the back, the same side of the two guide rail channel steel 104 is fixed with the connecting plate 417, the vertical rod of the guide rail 101 is fixed on the connecting plate 417 through the angle steel, due to the design of the angle steel at the butt joint surface, the guide rail groove is effectively reduced The steel 104 and the main frame pole 102 are vertically connected to each other, which improves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com