Device for preventing frequent movement of auxiliary steam header safety door of M701F combined circulation unit

A combined cycle unit, M701F technology, applied in the direction of engine starting, machine/engine, mechanical equipment, etc., can solve the problems of frequent operation of the safety door of the auxiliary steam main pipe, short service life of the safety door, abnormal auxiliary steam supply, etc., to achieve Avoid frequent movement, prolong service life, and prevent frequent movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

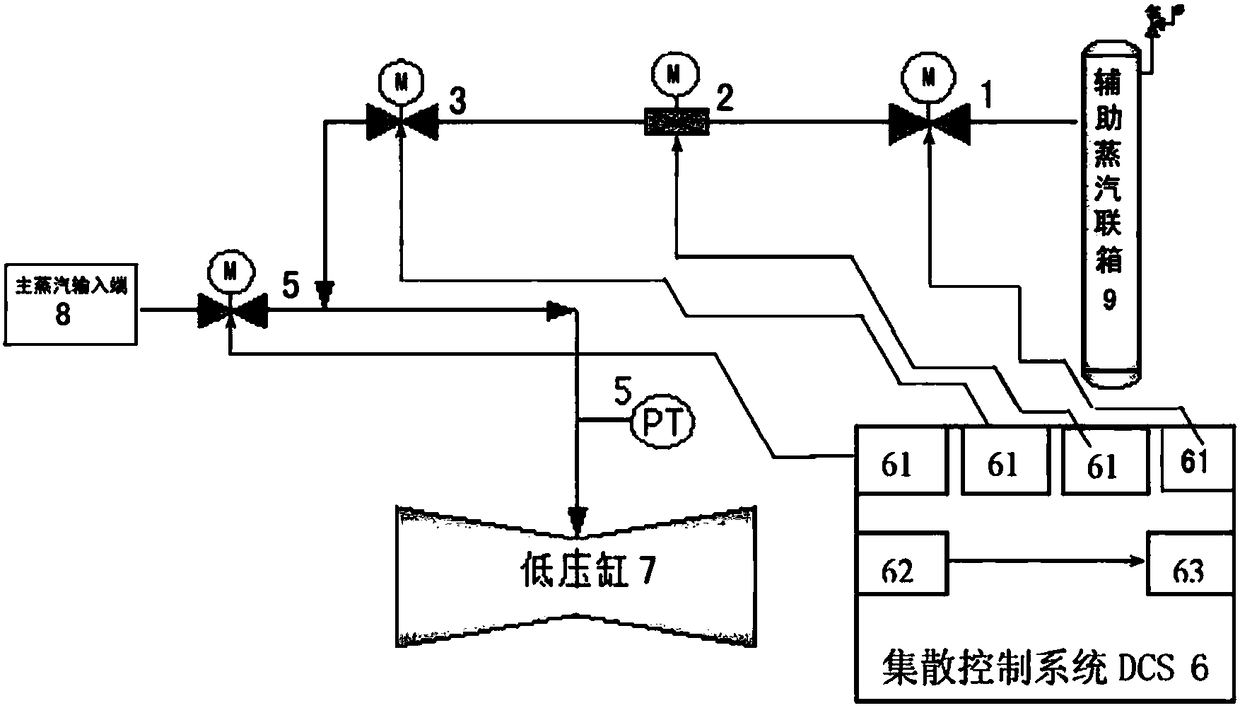

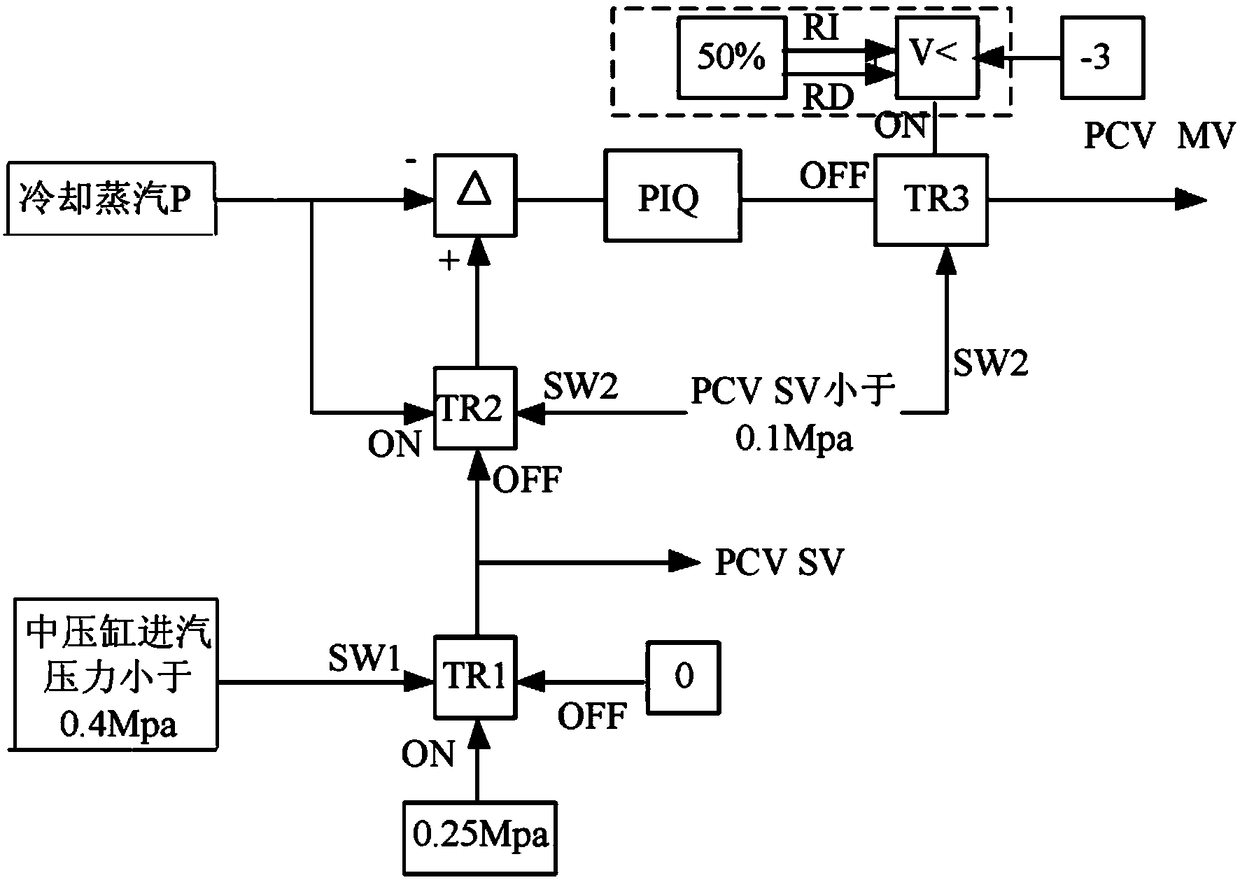

[0024] refer to figure 1 , the specific embodiment 1 includes a low-pressure cylinder 7 and an auxiliary steam header 9, the output end of the auxiliary steam header 9 is connected to the input end of the low-pressure cylinder 7, and the output end of the auxiliary steam header 9 is connected to the input end of the low-pressure cylinder 7 Set cooling steam cut-off door 1, cooling steam regulating door 2, cooling steam isolation door 3 and pressure sensor 5 in sequence, so that the output end of auxiliary steam header 9 passes through cooling steam cut-off door 1, cooling steam regulating door 2, cooling steam isolation The door 3 is connected to the low-pressure cylinder 7 to form an auxiliary steam circuit; the LP main steam input end 8 is connected to the input end of the low-pressure cylinder 7 through the electric main steam isolation door 4 to form the main steam circuit; the input end of the pressure sensor 5 is connected to the low-pressure cylinder 7, the signal The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com