Comprehensive controller and control method for sunlight greenhouse electric film rolling machine

A comprehensive controller, greenhouse electric roll technology, applied in non-electric variable control, greenhouse cultivation, control/regulation systems, etc., can solve the problem of not fully considering the sensitive factor of cost control, unable to meet the diversified operation requirements of farmers, reliability Insufficient design and other problems, to avoid power short circuit problems, improve scientific rationality, and solve time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

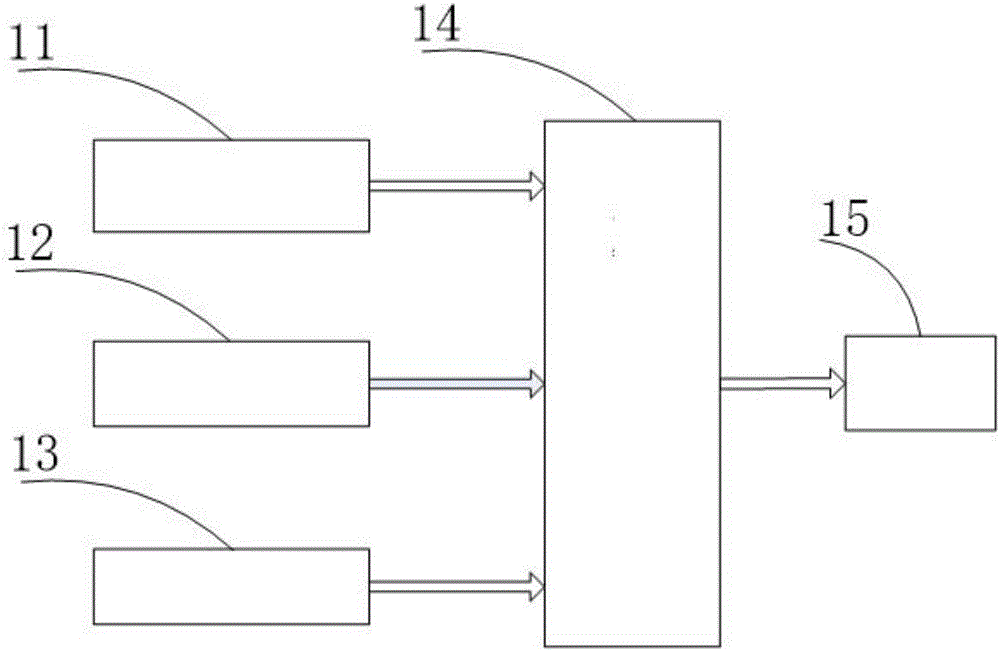

[0046] see figure 1 , a comprehensive controller for a greenhouse electric film rolling machine, which is composed of an automatic control unit 11, a remote control unit 12, a manual operation unit 13, and an interlocking linkage protection unit 14; the automatic control unit 11, the remote control unit 12, and the manual operation unit 13 are The interlock linkage protection unit 14 is connected to the electric film winding machine.

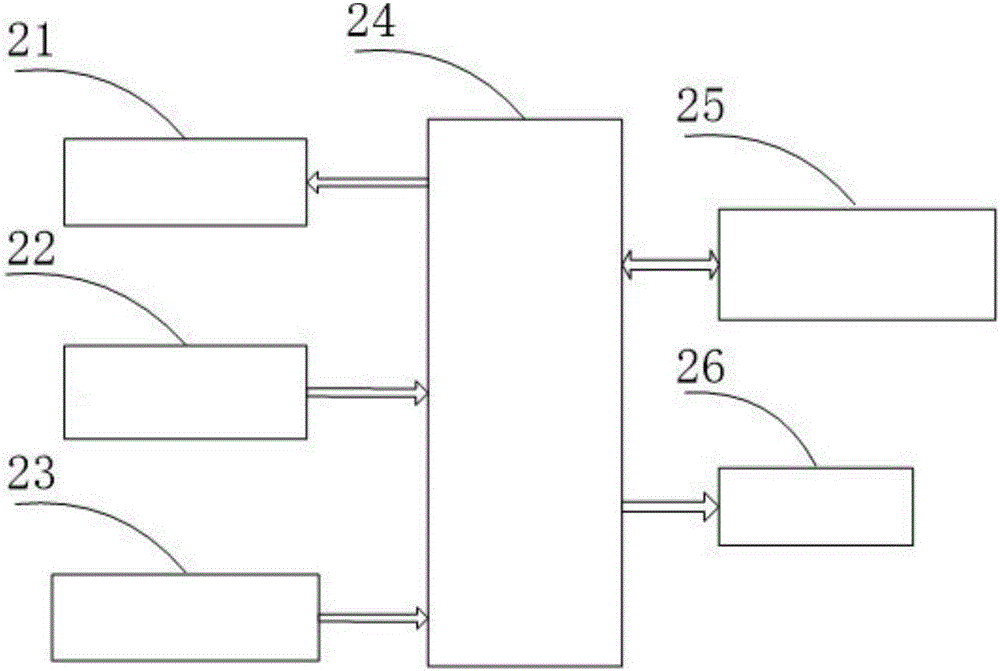

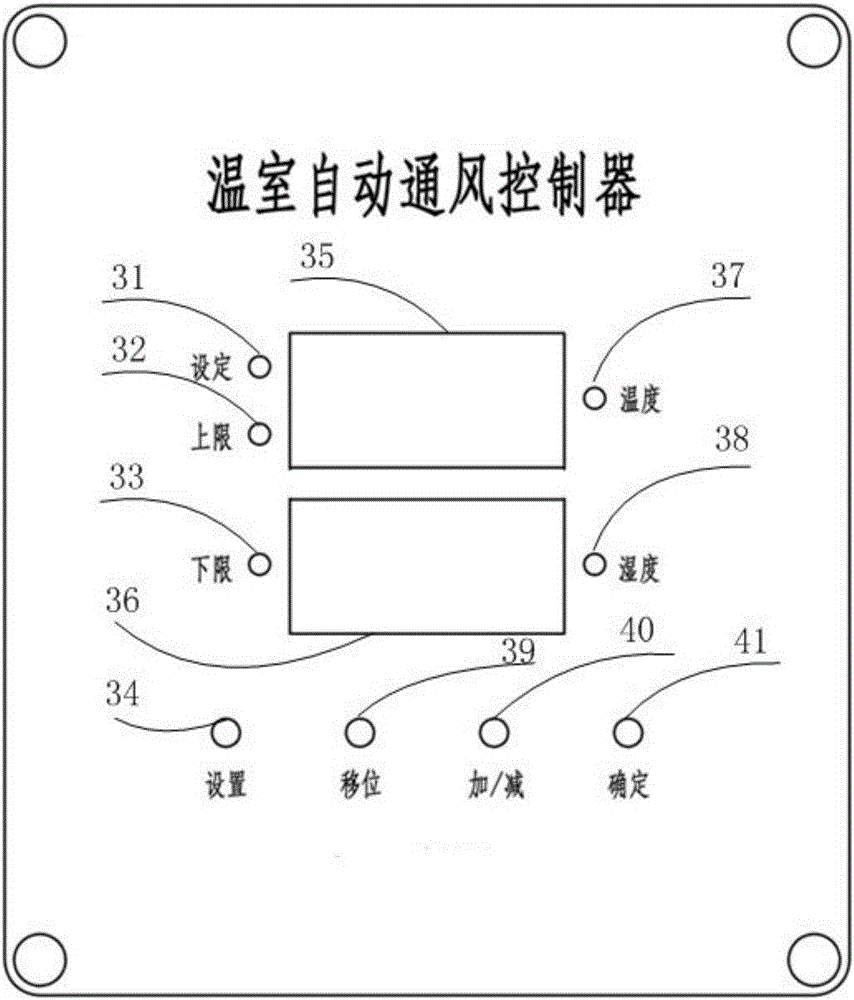

[0047] figure 2 It is a schematic diagram of the automatic control unit 11 : it includes an output relay 26 , a temperature and humidity sensor 23 , a data memory 25 and a 32-bit processor 24 .

[0048] The temperature and humidity sensor 23 adopts AM2320, and the communication interface adopts a standard IIC bus, and the length of the lead wire can work reliably between 5-15 meters during application. The temperature measurement ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com