Adjustable two-way float valve and working method thereof

A float valve and adjustable technology, applied in the direction of the float of the control valve, the operation/release device of the valve, the lift valve, etc., to achieve the effect of accelerating separation, reducing the labor intensity of workers, and ensuring the quality of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

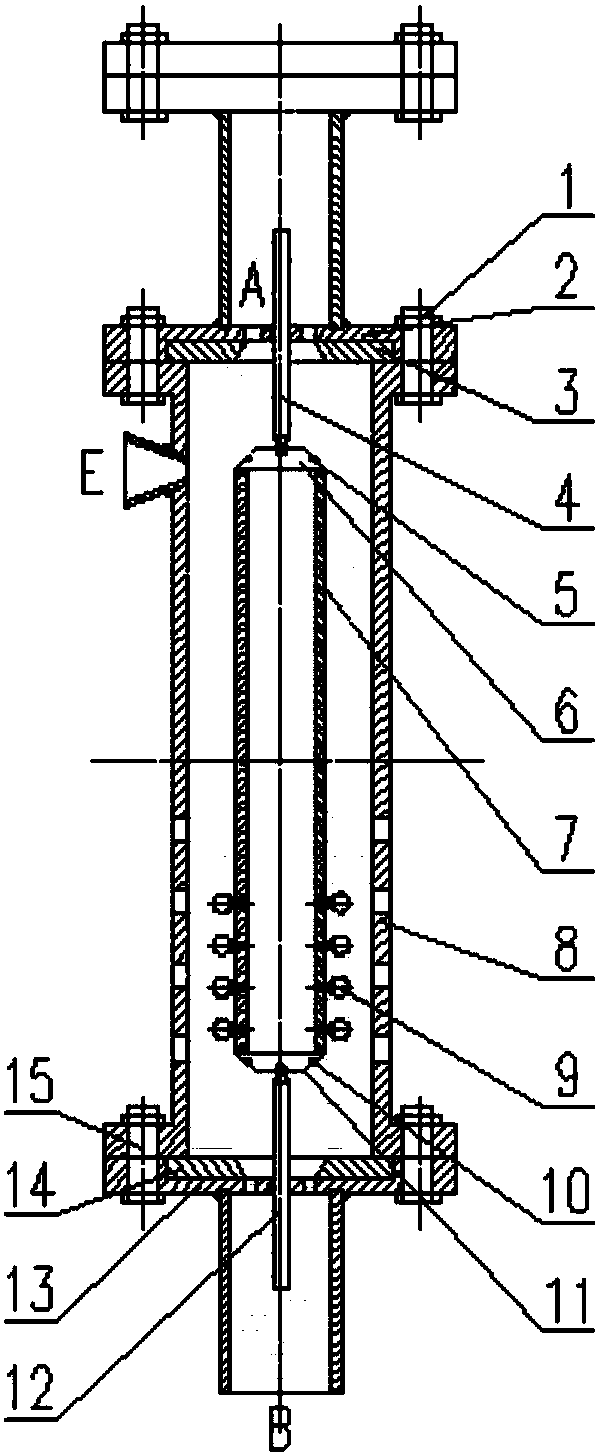

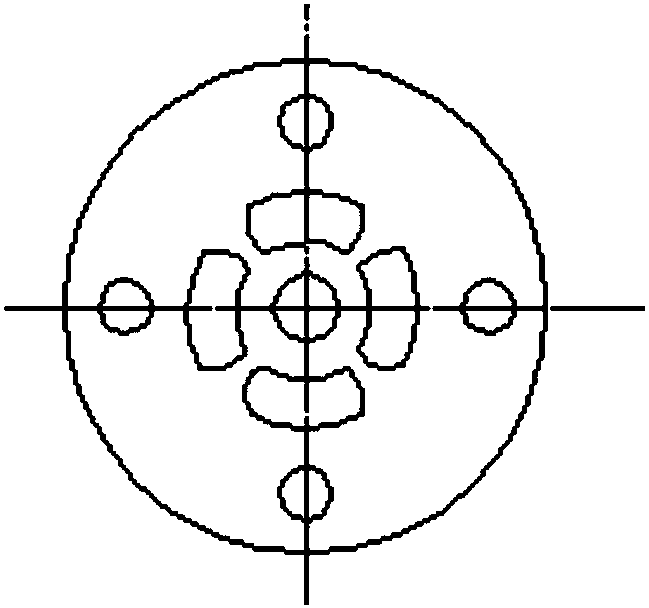

[0026] see figure 1 and figure 2 , an adjustable two-way float valve, mainly including cylinder body 8, upper valve seat 3, lower valve seat 14, upper cone valve body 6, lower cone valve body 11, float cylinder 7, upper flexible guide rod 4, lower flexible guide rod Rod 12, buoyancy regulator 9.

[0027] There is a gas acceleration port E on the top of the cylinder 8, with a taper of 10° to 25°, and several liquid inlets below; the upper valve seat 3 and the lower valve seat 14 are respectively pressed against the upper flange 2 and the lower flange 13. The upper and lower ends of the cylinder 8, the upper flange 2 is connected with the upper end of the cylinder 8 through several upper bolts 1, the lower flange 13 is connected with the lower end of the cylinder 8 through several lower bolts 15, the upper flange 2, the lower flange 13 It is in the shape of a divers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com