Immersion test method for fiber monofilament corrosion resistance test

A test method and anti-corrosion technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of fiber floating, long-term test without mentioning, fiber loss, etc., and achieve economical and simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

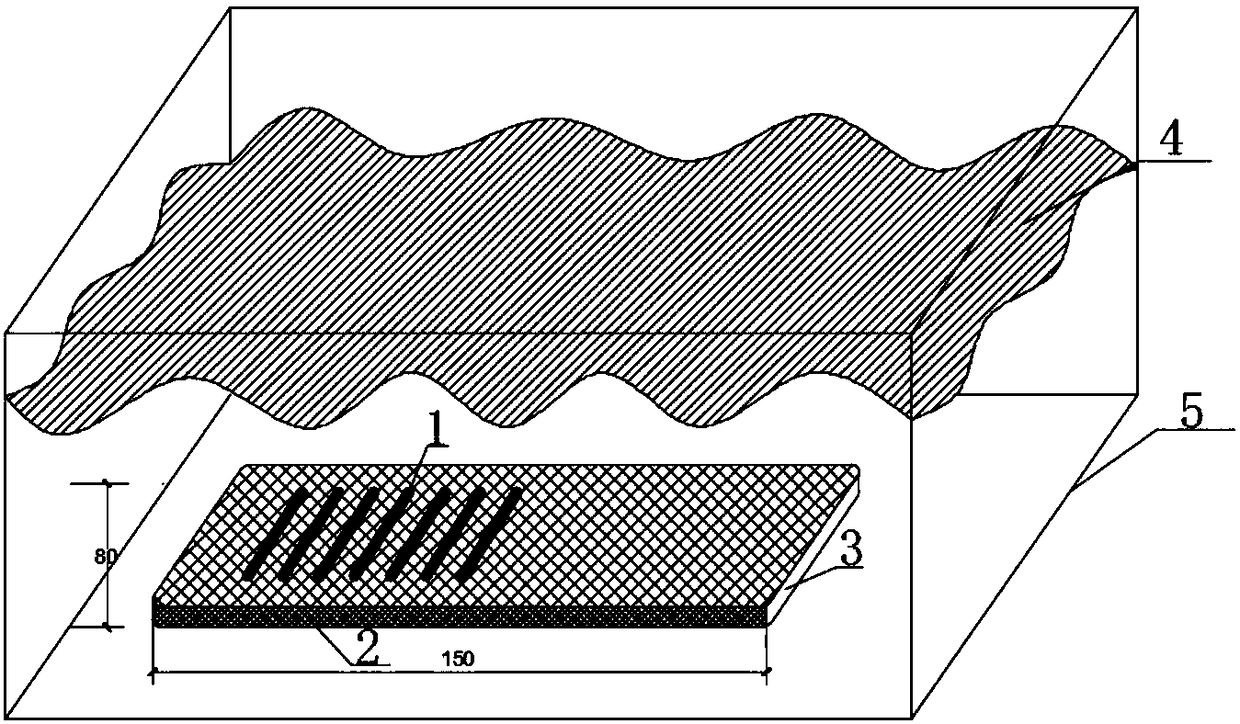

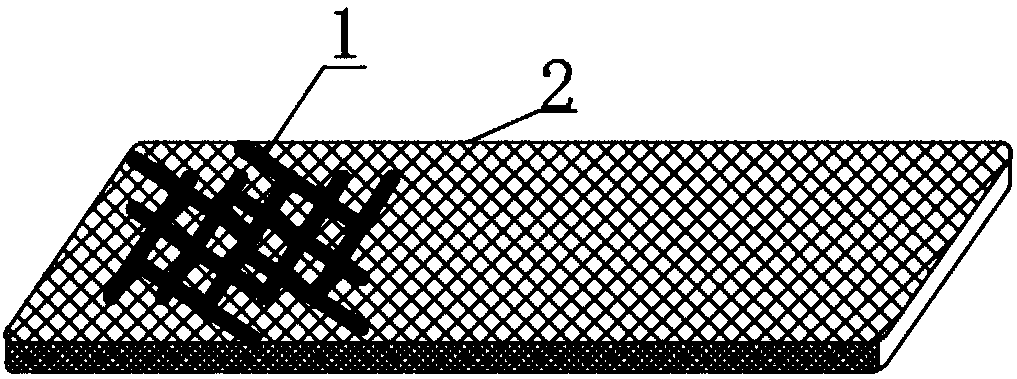

[0019] like figure 1 and figure 2 , taking polypropylene fiber (PP) soaking as an example, prepare a corrosion resistance test solution (1mol / L sodium hydroxide solution) in the soaking container 5 (2.5L storage box) in advance, and then weigh the fiber monofilament 1 (2gPP) Put it into a cloth bag 2 with a specification of 150mm×80mm (the size of the cloth bag can be adjusted according to the number of soaked fibers, so that the fibers can be dispersed and soaked in the cloth bag to ensure that the solution can erode most of the fibers), and the fiber monofilament 1 of the cloth bag opening 3 Move to the bottom of the bag 2, mark it and put it into the sodium hydroxide solution. Use tweezers (the chuck of the tweezers must have a certain curvature, not too sharp, or apply a layer of glue on the tip to make it smooth, so as to prevent the fiber from being damaged when the fiber is picked. But at the same time, it is also necessary to ensure that it can be clamped effectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com