Intelligent capacitor film precision detection system

A capacitor film, precision detection technology, used in instruments, measuring devices, scientific instruments, etc., can solve problems such as protrusions, difficult product quality control, and large losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

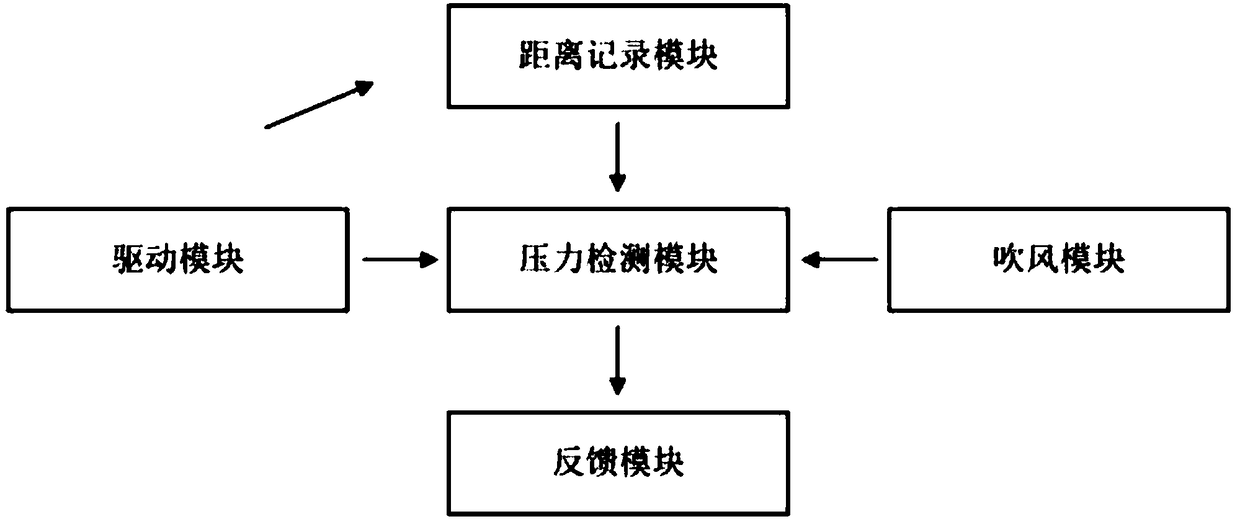

[0019] refer to figure 1 , an intelligent capacitor film precision detection system proposed by the present invention, the capacitor is made of a plastic film with a metal layer on one side, and the system includes: N pressure detection modules, N pressure detection modules used in conjunction with the N pressure detection modules A distance record module, a blower module, a drive module, and a feedback module;

[0020] The blowing module is used to blow the plastic film so that the metallized layer of the plastic film is close to the N pressure detection modules and the N distance recording modules, and the wind direction of the blowing module is perpendicular to the plastic film.

[0021] In a specific solution, when the plastic film is not coated with a metal layer, the plastic film is blown with a wind perpendicular to the plastic film, so that the metal-plated layer of the plastic film is close to the pressure detection module.

[0022] The N pressure detection modules a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com