A kind of manufacturing method of high voltage fast soft recovery diode

A manufacturing method and diode technology, which are used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as lack of complete process design, inability to take into account performance and reliability, and affecting the quality of high-voltage fast soft recovery diodes. , to achieve fast and reverse recovery characteristics, improve fast recovery characteristics, and reduce the effect of terminal leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

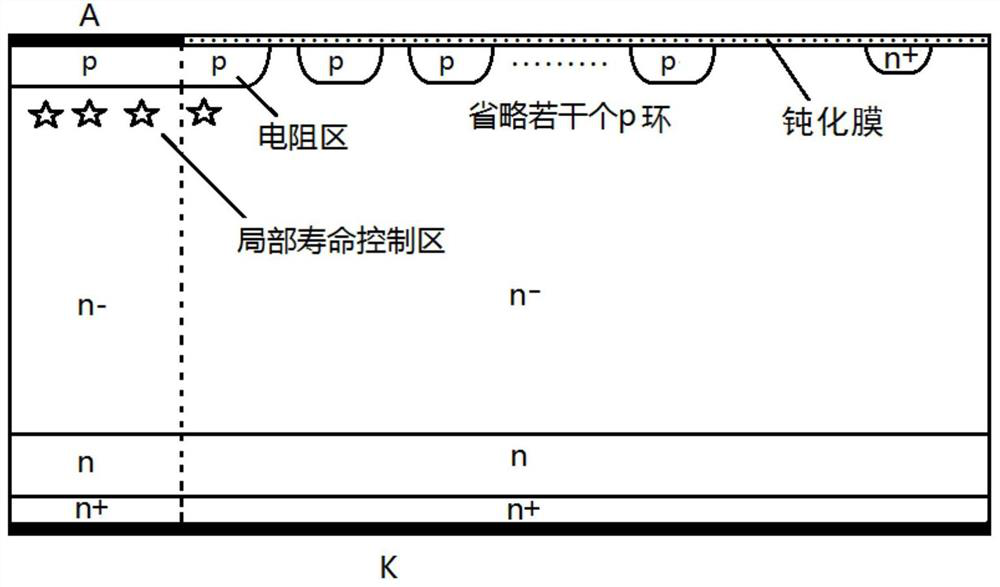

[0036] The manufacturing method of the high voltage fast soft recovery diode of the present invention is implemented according to the following steps:

[0037] Step 1. Select the original high-resistance melting neutron transmutation doped (NTD) single crystal silicon wafer, and polish it on both sides; 13 ~1×10 15 cm -2 , and the inclination angle is 7°, the phosphorous ion (P + ) injection, and then annealed at 850°C for 30 minutes to eliminate P + Lattice damage caused by implantation; then, in the range of 1150-1200°C, alternately carry out the oxidation reaction of dry oxygen-wet oxygen-dry oxygen for 9 hours to form a masking film on the surface of the silicon wafer; advance at a high temperature of 1250°C for 15-20 hours , forming an n-buffer layer, the resulting profile is as Figure 2a shown;

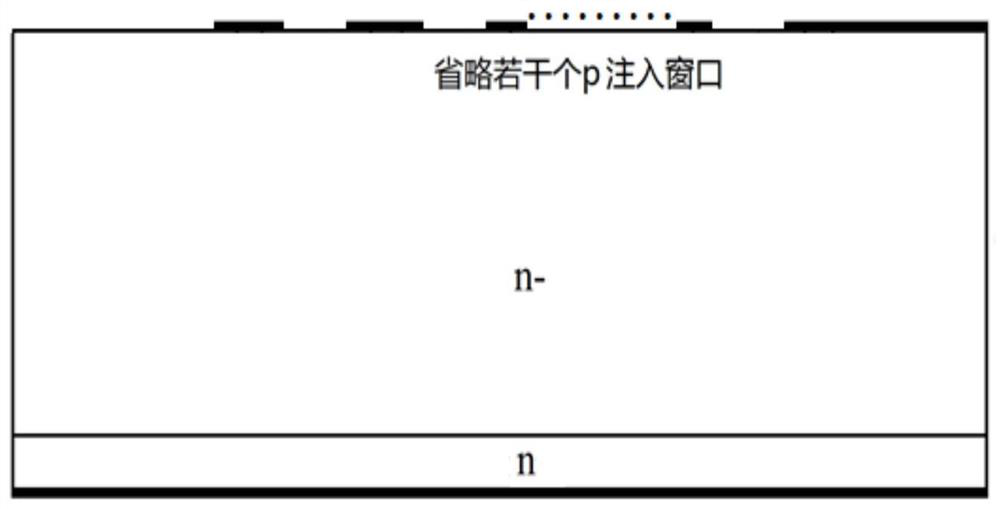

[0038] Step 2. Perform photolithography on the upper surface of the silicon wafer treated in step 1 to form boron ion implantation windows in the active region and the ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com