Chip strip type rigid framework-based chip packaging structure and process thereof

A chip packaging structure and rigid frame technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of low processing efficiency and unfavorable chip mass production, so as to improve work performance, improve processing efficiency and output, and improve heat generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described below in conjunction with accompanying drawing.

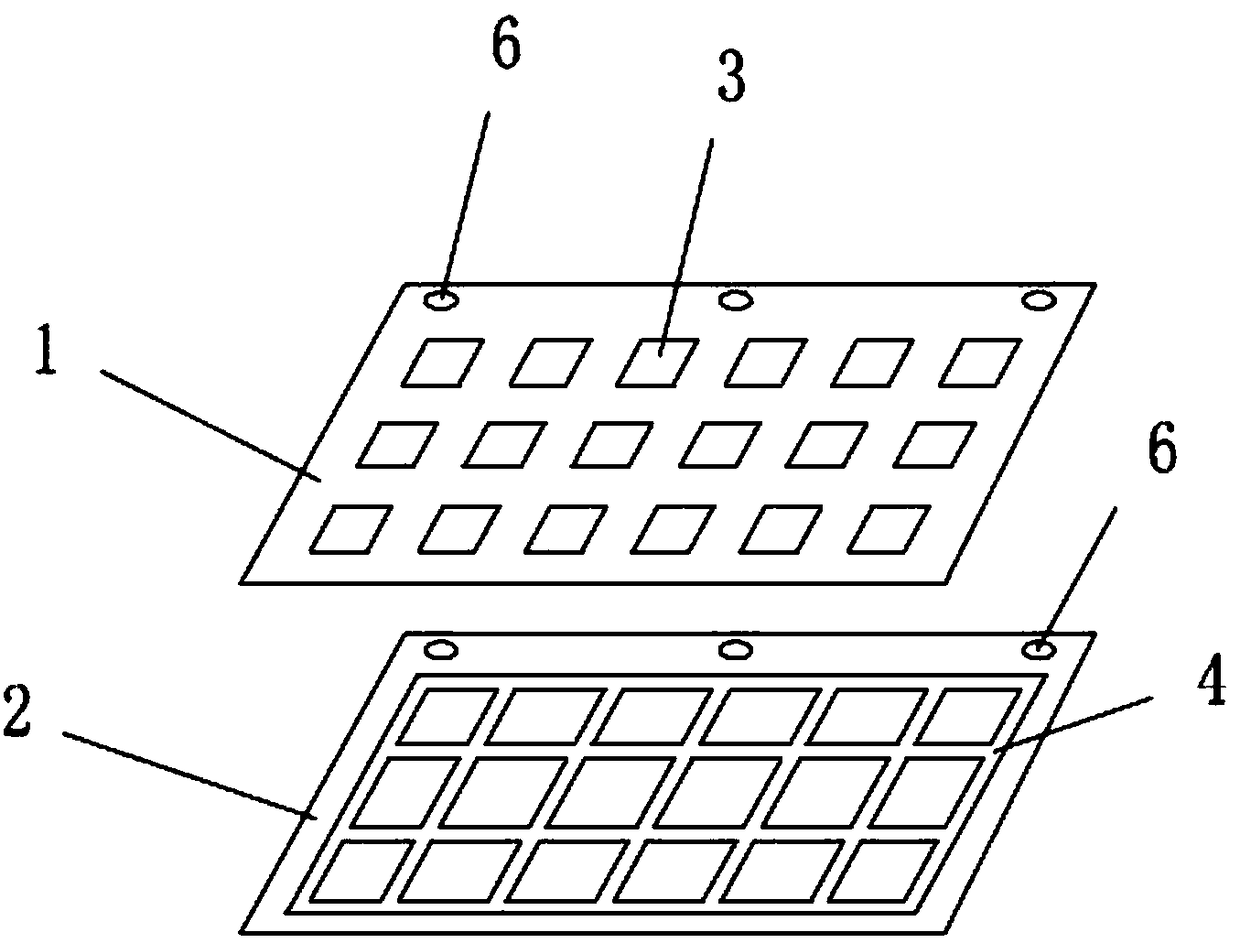

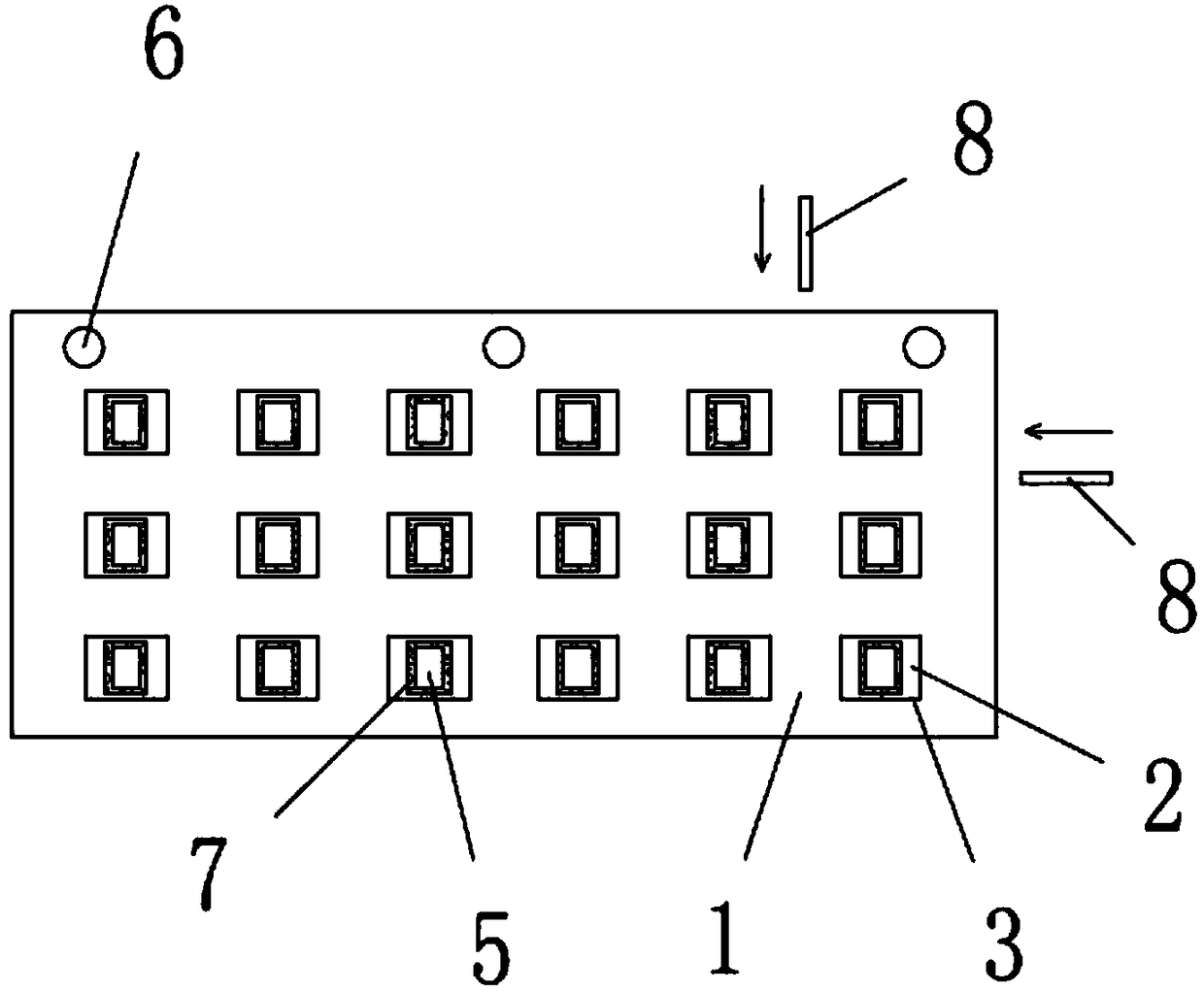

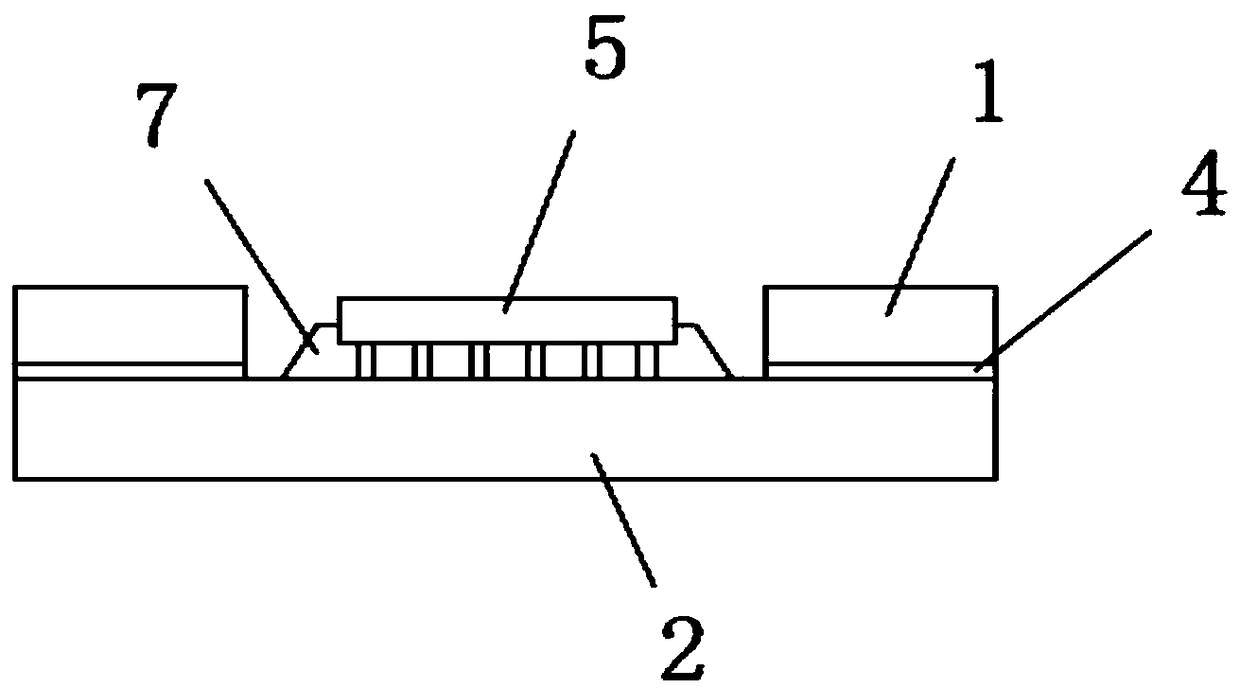

[0027] as attached Figure 1-2 As shown, a chip packaging structure based on a strip-type rigid frame according to the present invention includes a rigid frame 1 and a chip packaging substrate 2, and both the rigid frame 1 and the chip packaging substrate 2 are elongated sheet structures; The rigid frame 1 is provided with a plurality of uniformly arranged chip mounting holes 3, the chip packaging substrate 2 is provided with an adhesive layer 4, and the rigid frame 1 and the chip packaging substrate 2 are provided with a plurality of corresponding positioning holes 6, The rigid frame 1 and the chip packaging substrate 2 are positioned and aligned through the positioning holes 6, and are bonded through the adhesive layer 4; the adhesive layer 4 is a mesh structure, and the vacated part of the mesh structure corresponds to each chip mounting hole 3 , so that the adhesive layer 4 avoids ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap