Automatic punching equipment for iron pipe and aluminum pipe

A technology of automatic punching and equipment, applied in the direction of pushing equipment, metal processing equipment, punching tools, etc., can solve the problems of high labor cost, lack of integrated completion, and long time consumption in the punching process, so as to reduce time consumption, The effect of saving human resources and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

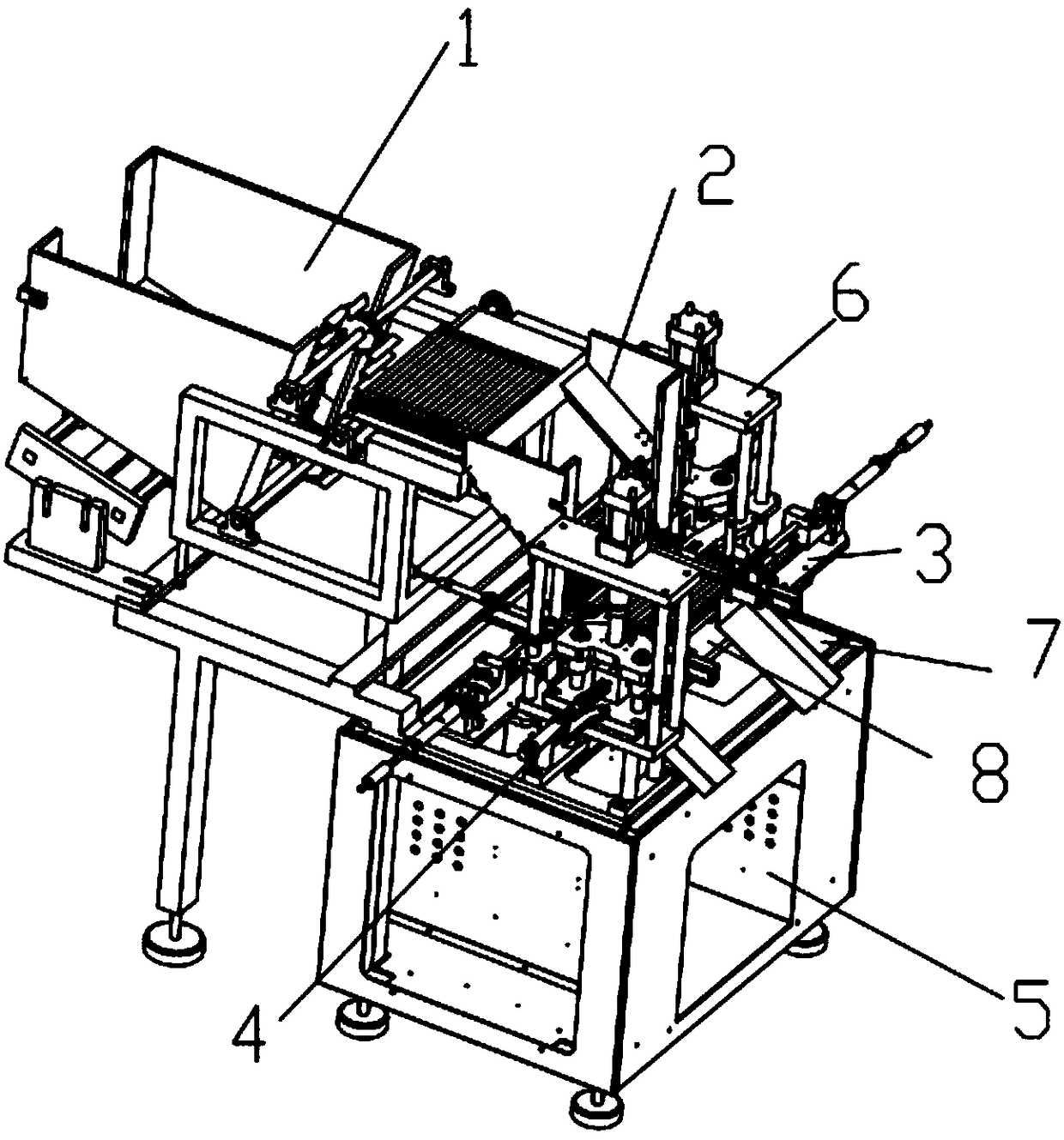

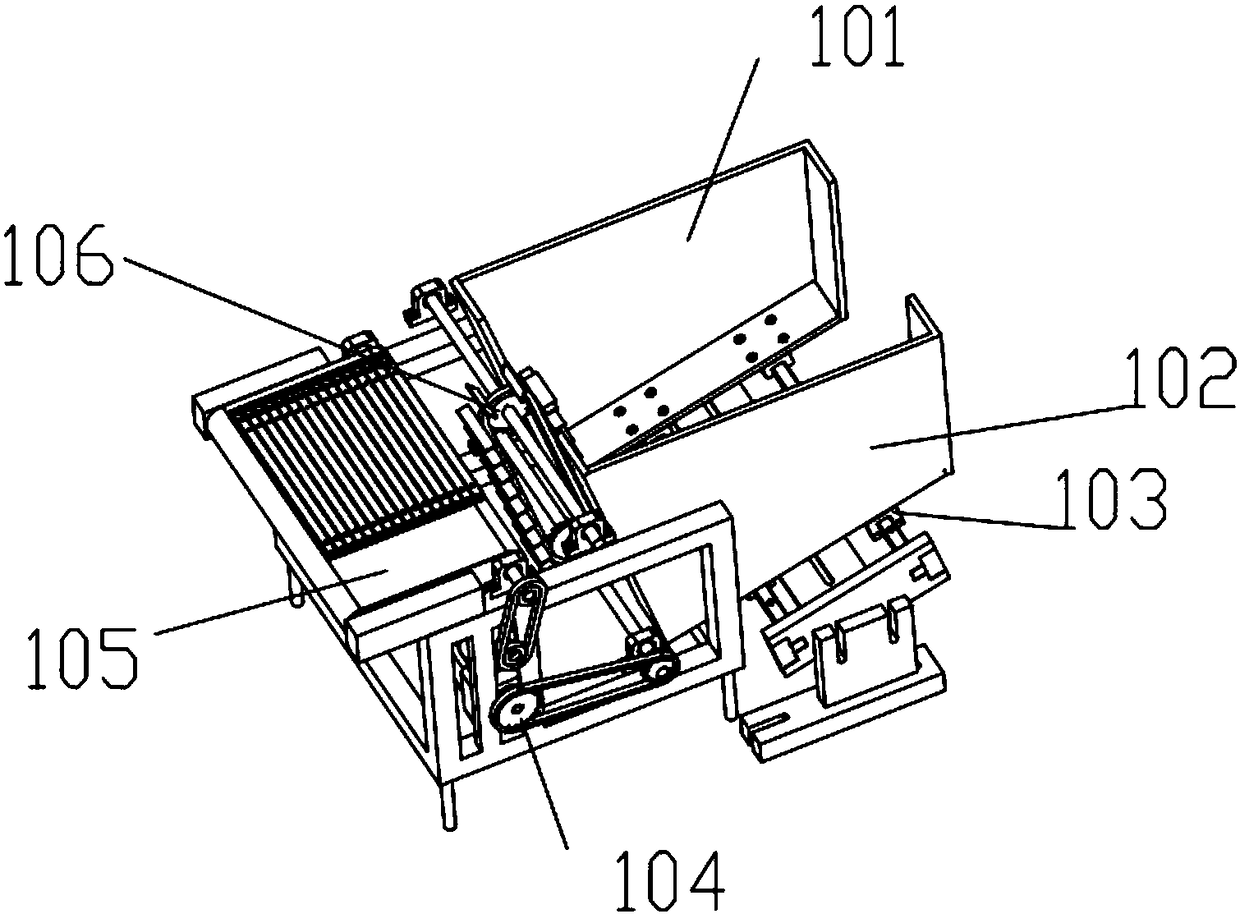

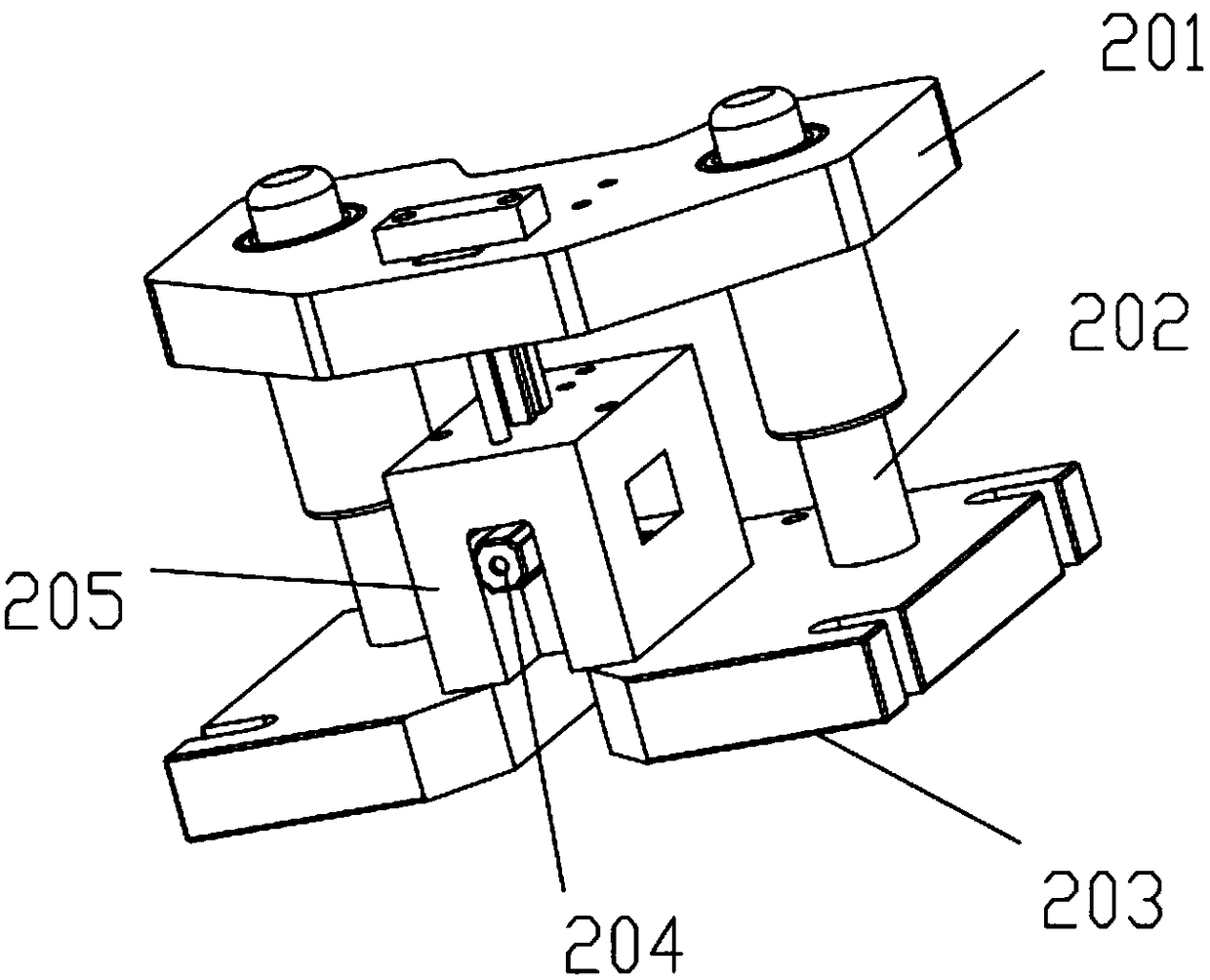

[0027] Please refer to Figure 1 to Figure 9 , an automatic punching equipment suitable for iron pipes and aluminum pipes, including a pipe automatic feeding assembly part 1, a pipe material feeding and distribution assembly part 2, a pipe pushing mold part 3, and a pipe unloading assembly set on an equipment shelf 5 Out of the mold group 4, the pipe material automatic feeding combination part 1 is connected with the pipe material passing and distributing combination 403 part 2, and the pipe material passing and distributing combination 403 part 2 is provided with a mold fixing Hydraulic frame 96, the pipe pushing die set is connected with the pipe unloading die set 4 through the pipe length adjusting slide 8, the pipe pushing die set, the pipe length adjusting slide 8 and the pipe unloading die set 4 are all located in the equipment On the shelf 5 is a large board 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com