Pineapple copying fixed-point cutting machine

A cutting machine and pineapple technology, applied in the field of pineapple profiling fixed-point cutting machine, can solve problems such as low efficiency, and achieve the effects of reducing manual operation, realizing utilization, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

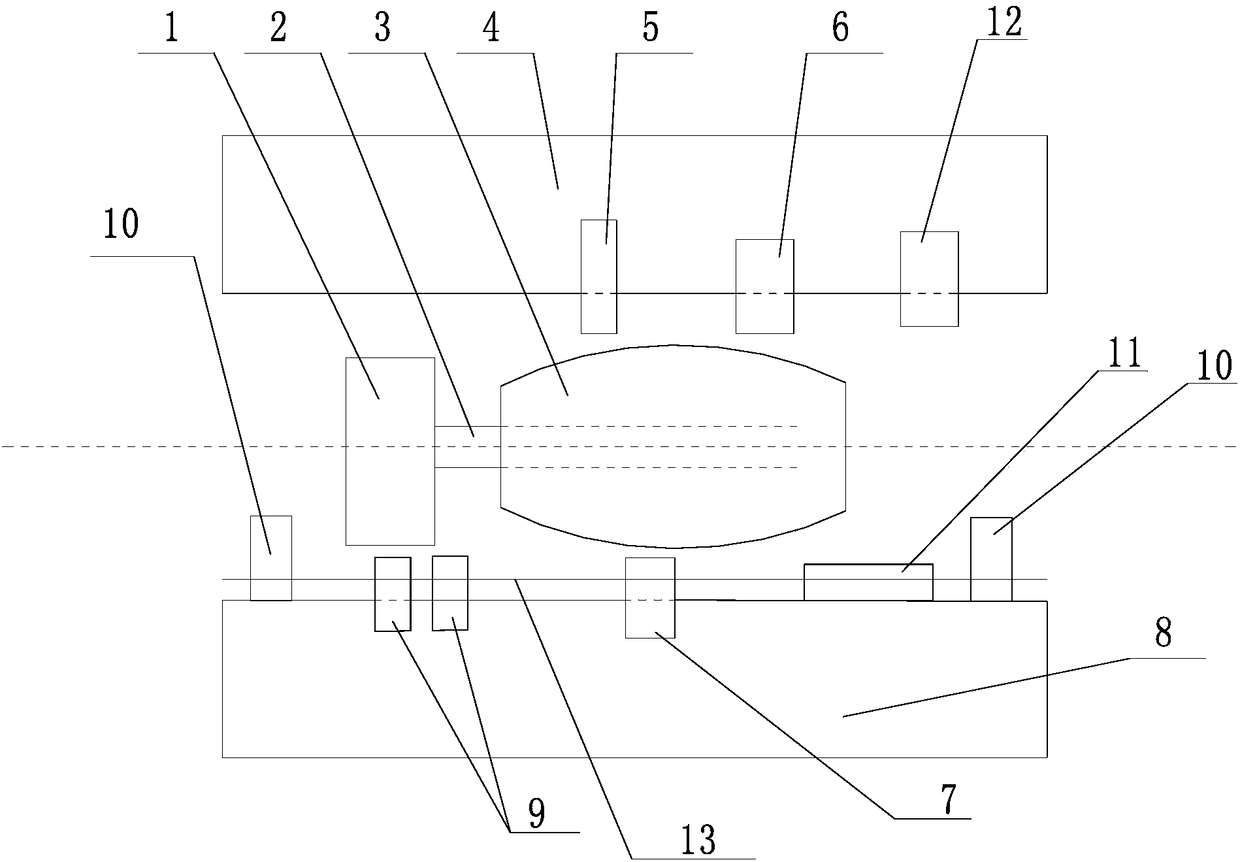

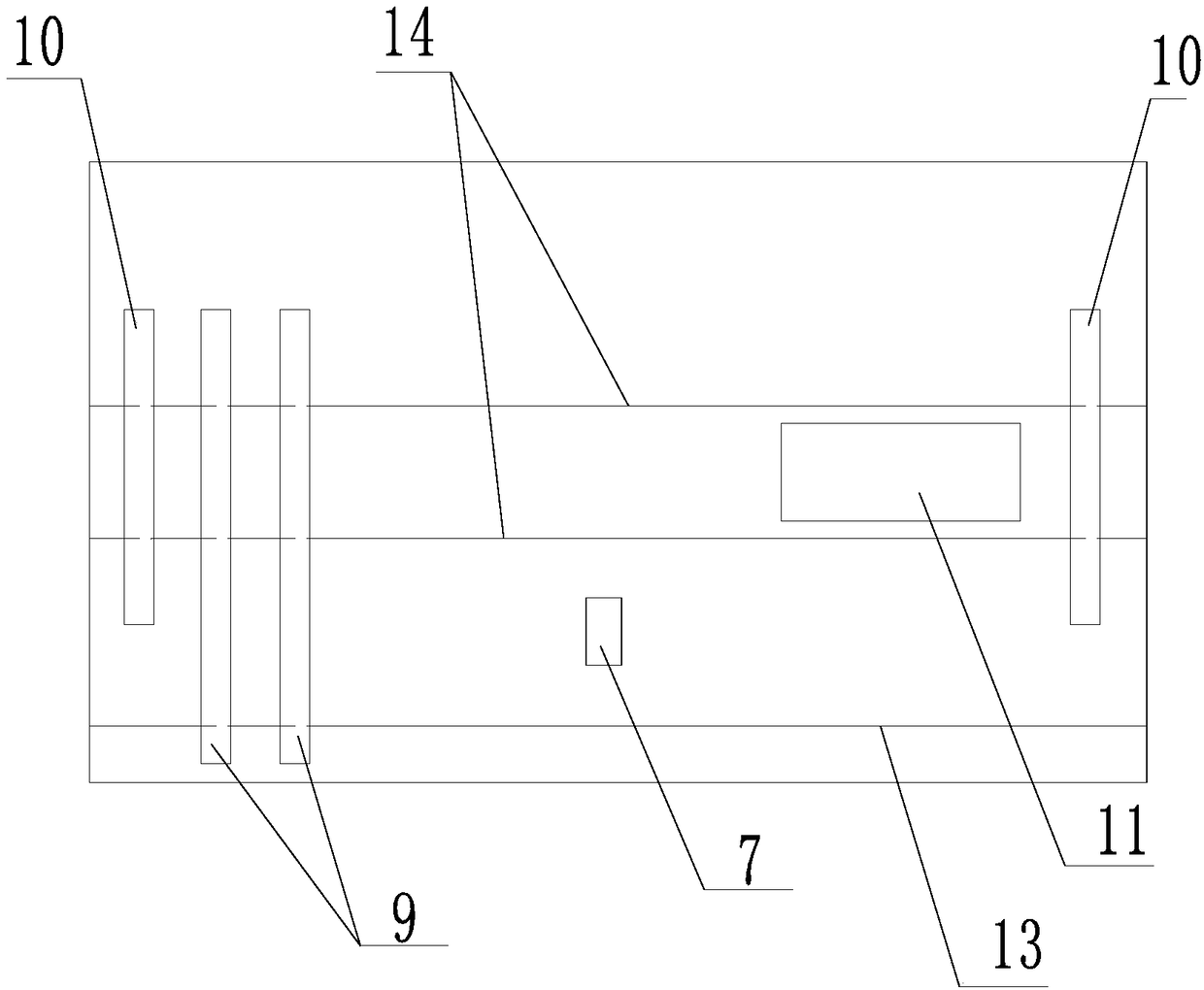

[0016] like Figure 1-2 As shown, a pineapple profiling fixed-point cutting machine includes a rotary table 1, a core member 2, an upper workbench 4, a fixed-point conical milling cutter 5, a machine vision recognition system 6, a cutting knife 7, a lower workbench 8, a cutting Tool 9, chuck 10, conveying mechanism 11, digital controller and photoelectric detection system 12; fixed-point conical milling cutter 5, photoelectric detection system 12 and machine vision recognition system 6 are arranged on the upper workbench 4, and its fixed-point conical milling Knife 5 is selected as a spiral taper milling cutter; the lower table 8 is provided with a cutting knife 7 and a cutting tool 9; the lower table 8 is provided with a horizontally placed slide bar 13; the cutting tool 9 is connected with the slide bar 13; the conveying mechanism 11 includes clamping tools, driving motors, pulleys and conveyor belts; the conveying mechanism 11 is placed in the middle of the lower workbench ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com