Adjustable high-vibration-isolation-performance automobile seat suspension structure

A technology for car seats and performance, applied in seat suspension devices, vehicle seats, special positions of vehicles, etc., can solve the problems of complex structure, high cost, and high energy consumption, and achieve good riding comfort and structure. Simple, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

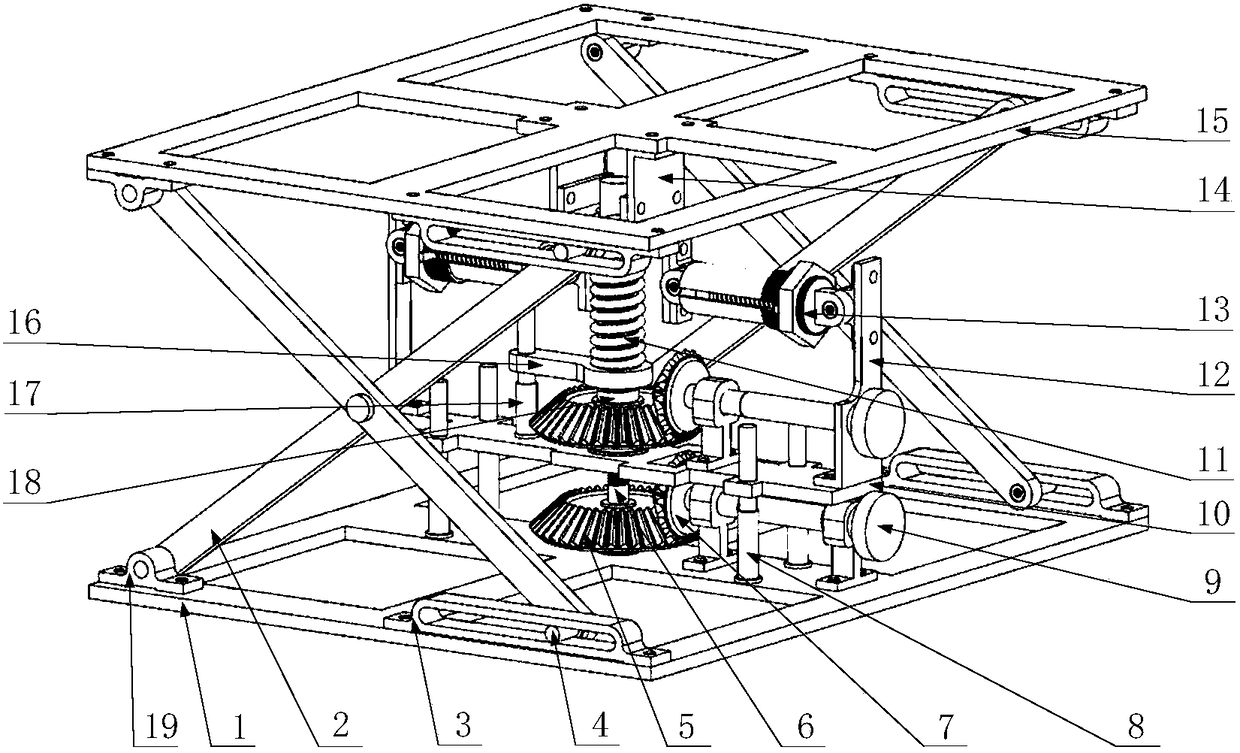

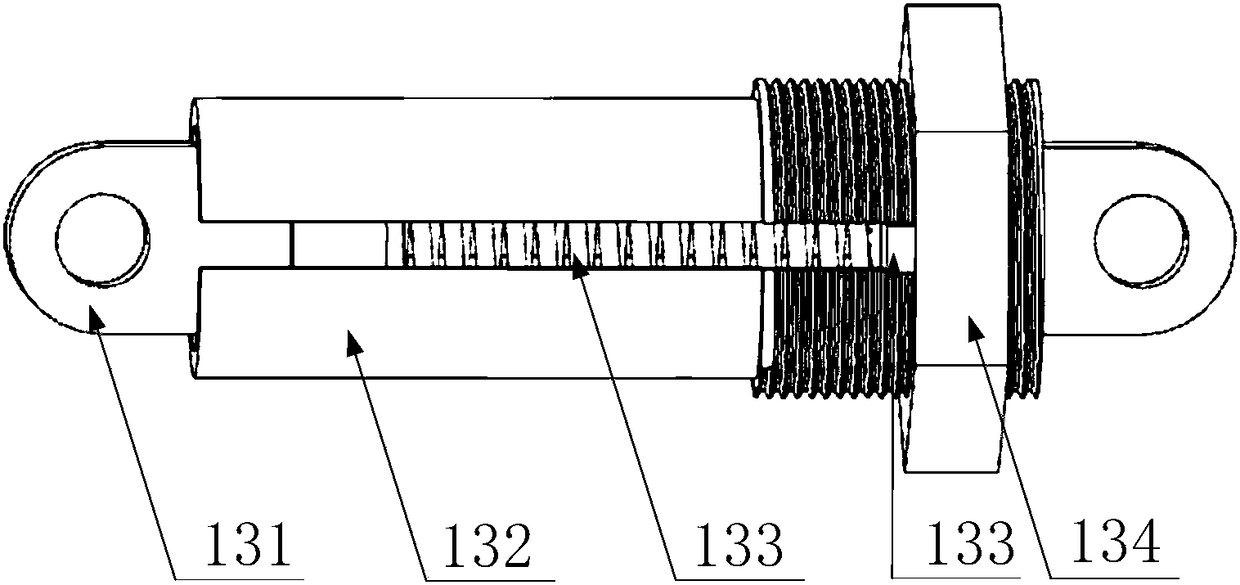

[0026] The embodiment is basically as attached figure 1 , 2 Shown: a kind of adjustable high vibration isolation performance car seat suspension structure provided by the present embodiment, comprises the lower mounting plate 1 that is fixed on the car floor (not shown), the bearing car seat (not shown) The upper mounting plate 15 and the height adjustment assembly, the lower moving plate 10, the working point adjustment assembly, the upper moving plate 16, the quasi-zero stiffness assembly and the installation Support 14; the height adjustment assembly can make the car seat adapt to drivers and passengers of different heights, which is arranged on the lower mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com