A kind of manganese series phosphating solution and its application

A manganese-based phosphating solution and solvent technology, applied in the direction of metal material coating process, etc., can solve the problems of long phosphating film formation time, slow phosphating reaction speed, uneven phosphating film roughness, and achieve film forming speed. Fast, reduced polarization potential, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

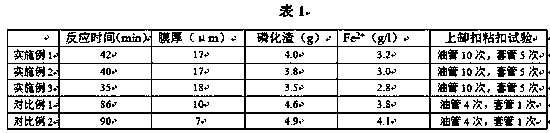

Embodiment 1

[0031] Mix Marzoff salt, sulfuric acid, ammonium molybdate, sodium fluorosilicate, copper sulfate pentahydrate, and 1,10-phenanthroline to obtain a phosphating concentrate, and then follow the phosphating concentrate: water = 1:4 ( weight ratio) to obtain a manganese-based phosphating solution.

[0032] Among them, the content of each component in the manganese-based phosphating solution is as follows: Maziv salt 195 g / L, sulfuric acid 60 g / L, ammonium molybdate 4 g / L, sodium fluorosilicate 3.5 g / L, pentahydrate Copper sulfate 0.6g / L, 1,10-phenanthroline 1.1 g / L.

[0033] Among them, the total acidity of the phosphating solution is TA 80-130; the free acidity is FA10-22.

[0034] Use this manganese-based phosphating solution to phosphate the surface of V150 high-chromium alloy steel pipe ferrules. The entire operation process of the phosphating process is as follows: degreasing→water washing→activation (pickling)→surface adjustment→phosphating→water washing→passivation Phosp...

Embodiment 2

[0036] Mix Marzoff salt, sulfuric acid, ammonium molybdate, sodium fluorosilicate, copper sulfate pentahydrate, and 1,10-phenanthroline to obtain a phosphating concentrate, and then follow the phosphating concentrate: water = 1:4 ( weight ratio) to obtain a manganese-based phosphating solution.

[0037] Among them, the content of each component in the manganese-based phosphating solution is as follows: 375 g / L of Maziv salt, 70 g / L of sulfuric acid, 6 g / L of ammonium molybdate, 5.5 g / L of sodium fluorosilicate, copper sulfate pentahydrate 1g / L, 1,10-phenanthroline 1.3 g / L.

[0038] Among them, the total acidity of the phosphating solution is TA 80-130; the free acidity is FA10-22.

[0039] Use this manganese-based phosphating solution to phosphate the surface of V150 high-chromium alloy steel pipe ferrules. The entire operation process of the phosphating process is as follows: degreasing→water washing→activation (pickling)→surface adjustment→phosphating→water washing→passivat...

Embodiment 3

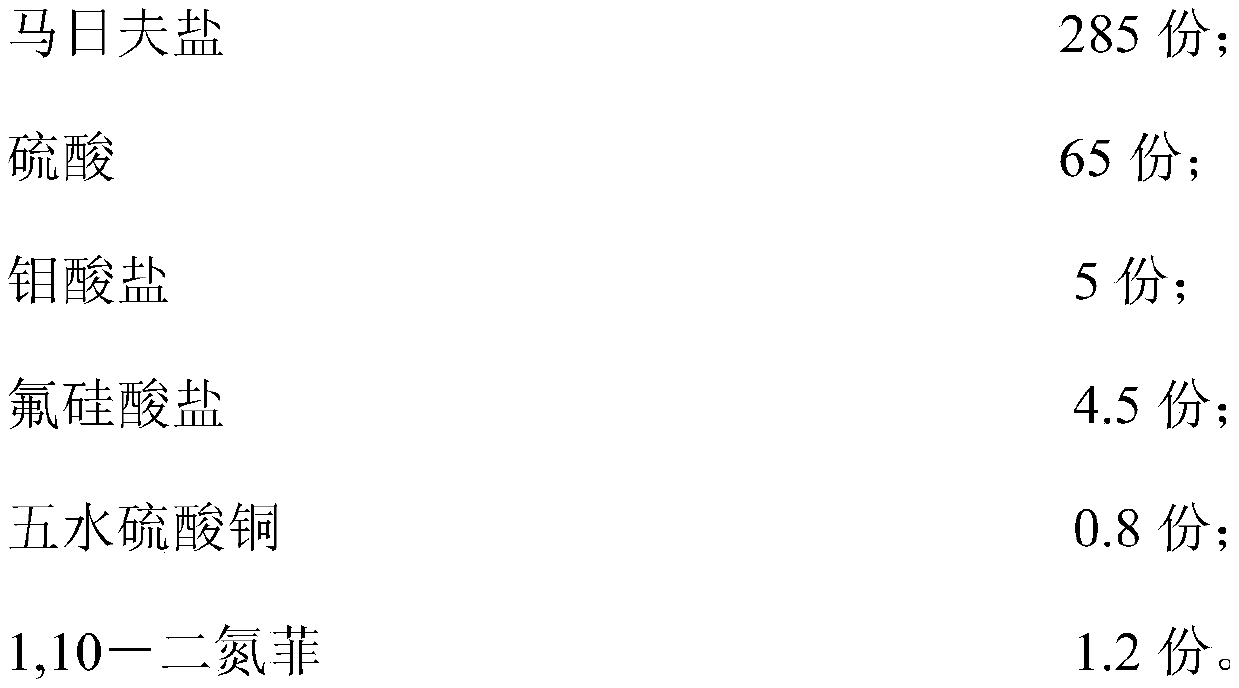

[0041] Mix Marzoff salt, sulfuric acid, ammonium molybdate, sodium fluorosilicate, copper sulfate pentahydrate, and 1,10-phenanthroline to obtain a phosphating concentrate, and then follow the phosphating concentrate: water = 1:4 ( weight ratio) to obtain a manganese-based phosphating solution.

[0042] Among them, the content of each component in the manganese-based phosphating solution is as follows: 285 g / L of Maziv salt, 65 g / L of sulfuric acid, 5 g / L of ammonium molybdate, 4.5 g / L of sodium fluorosilicate, 0.8 g / L of copper sulfate pentahydrate g / L, 1,10-phenanthroline 1.2g / L.

[0043] Among them, the total acidity of the phosphating solution is TA 80-130; the free acidity is FA10-22.

[0044] Use this manganese-based phosphating solution to phosphate the surface of V150 high-chromium alloy steel pipe ferrules. The entire operation process of the phosphating process is as follows: degreasing→water washing→activation (pickling)→surface adjustment→phosphating→water washing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap