Glove blank weaving method and glove blank

A glove and fiber technology, applied in the field of glove embryos, can solve the problems of poor strength, elastic wear resistance, tear resistance, cut resistance and puncture resistance, cumbersome weaving process, large demand, etc., and achieve excellent Abrasion resistance, low production cost, comfortable wearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1 proposes a kind of weaving method of glove embryo, comprises the following steps:

[0084] (1) A strand of polyamide 6 fiber (i.e. nylon filament) with a fineness of 14D twisted into a strand of nylon yarn is drawn, and the air pressure is 2.5x10 through the grid nozzle. 5 The compressed air of Pa, prepares nylon empty cover yarn;

[0085](2) A strand of spandex yarn twisted into a plurality of spandex filaments with a fineness of 70D is used as a core wire, and a strand of CoolMax fiber twisted into a plurality of CoolMax filaments is used by a covering machine to be spirally formed outside the core wire. The method is rotated and wound to obtain the CoolMax / spandex covered yarn with a layer of CoolMax fiber covered by spandex yarn;

[0086] In the preparation process of CoolMax / spandex covered yarn, the Ratio of spandex yarn is controlled to be 2.3 times, the twist of CoolMax fiber is 560 twists / meter, and the twist direction is Z direction, and the weig...

Embodiment 2~7

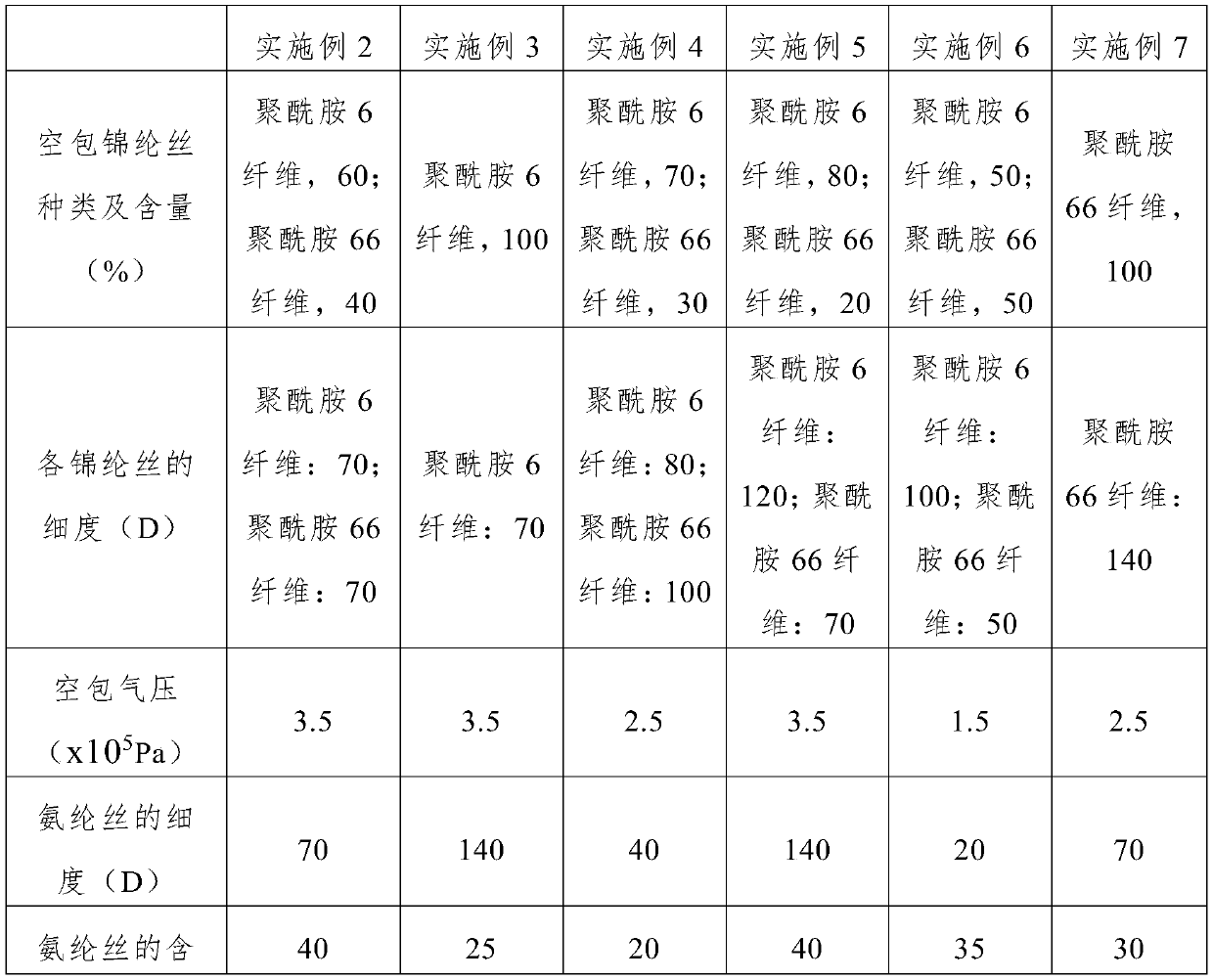

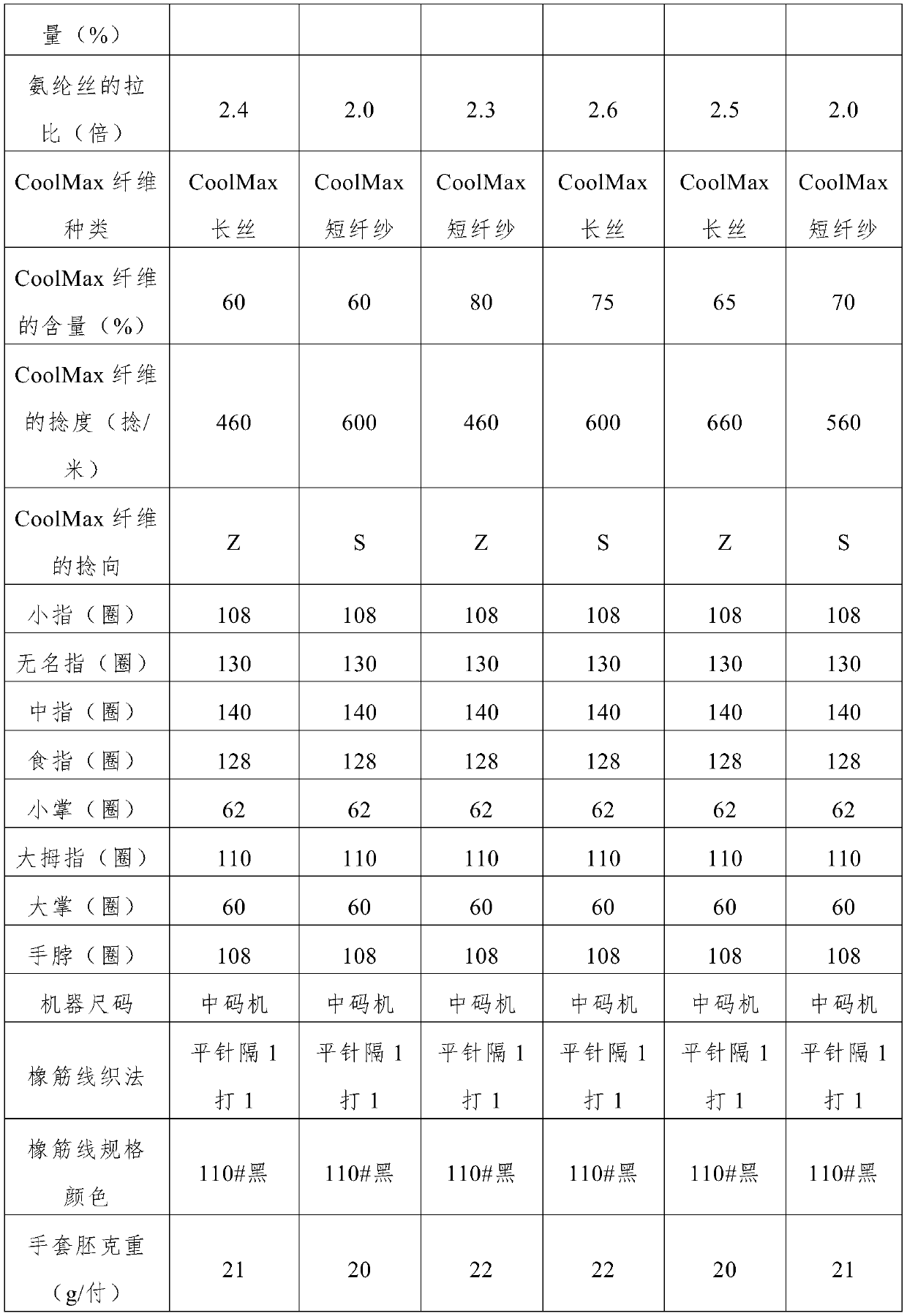

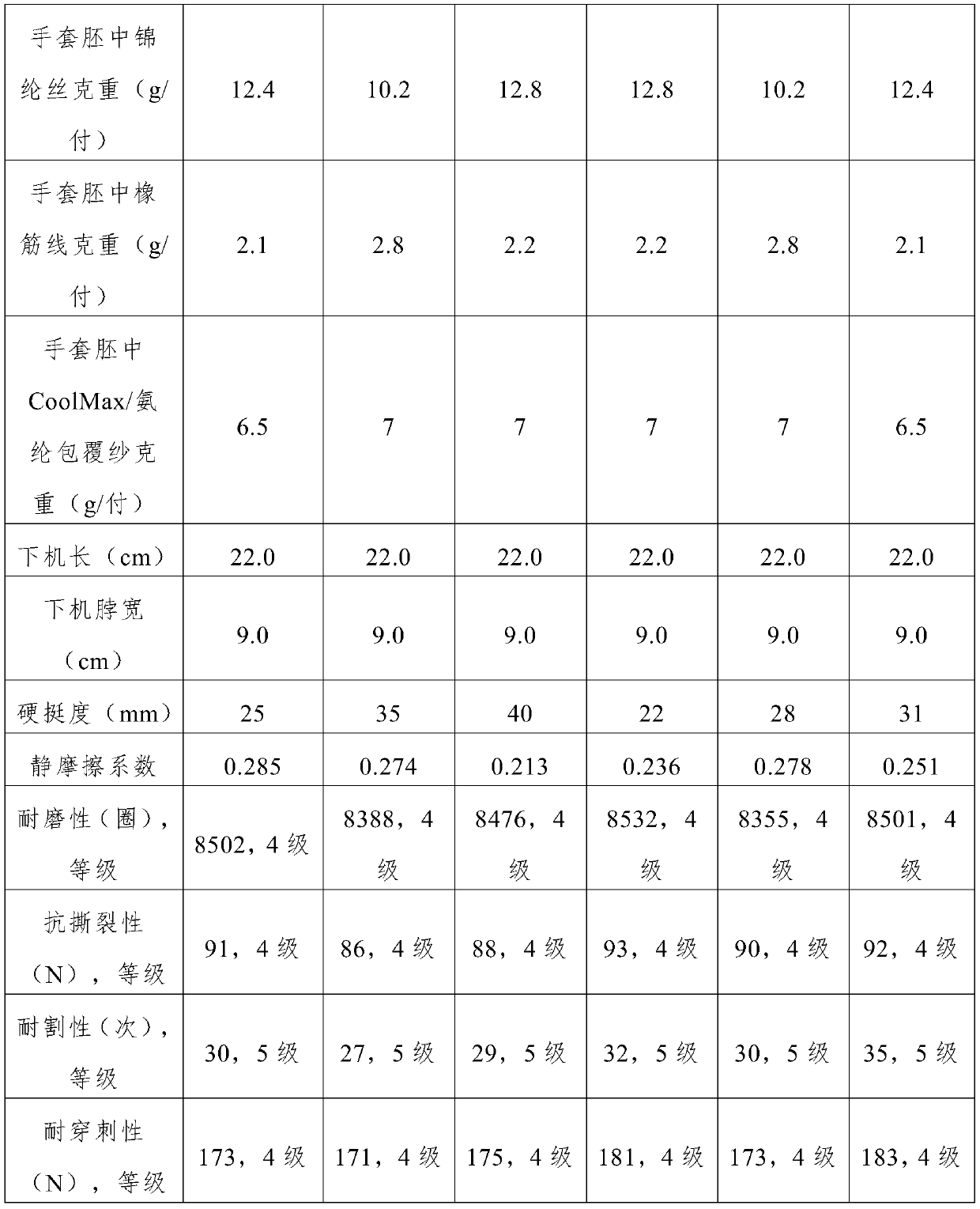

[0091] Similar to the weaving method of the glove embryo in Example 1, a method of weaving the glove embryo is proposed in Examples 2 to 7 respectively, by adjusting the type, content and fineness of the nylon filament, the air pressure of the air bag, and the fineness of the spandex filament And Rabi, the twist and twist direction of CoolMax fiber, the weight percentage preparation of spandex yarn and CoolMax fiber and other parameters to weave glove embryos with different performance requirements. The weaving parameters and performance test results of these glove embryos are shown in Table 1.

[0092] Table 1

[0093]

[0094]

[0095]

[0096] From Example 1 and the weaving parameters and performance test results of Examples 2 to 7 in Table 1, it can be seen that the present invention adopts nylon blank yarn and CoolMax covered spandex yarn to mix and weave glove embryos, and the woven gloves The embryo not only has the good hygroscopicity and air permeability char...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com